Introduction

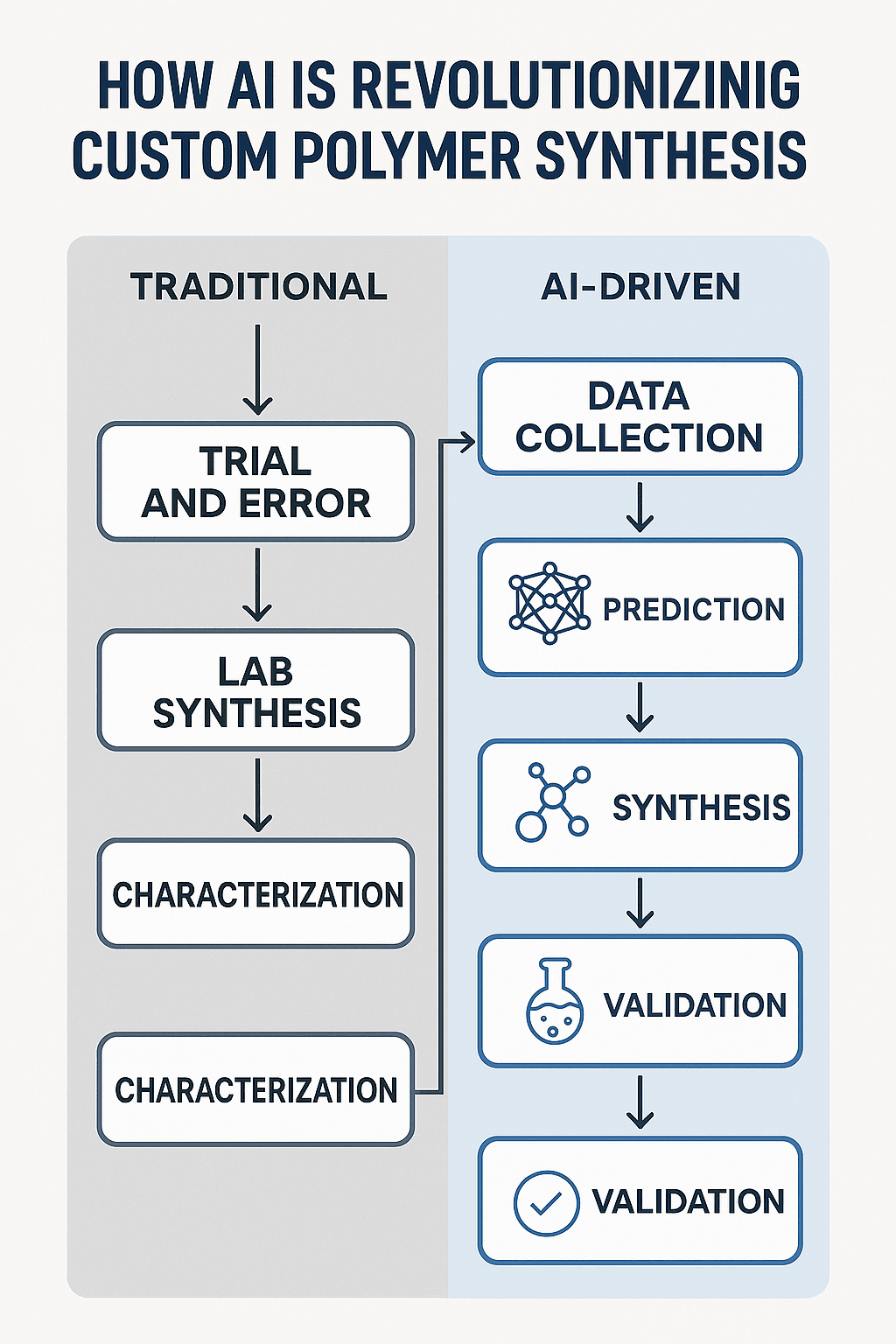

Custom polymer synthesis has become a cornerstone for advancing materials in industries such as healthcare, electronics, and sustainable packaging. However, the traditional trial-and-error approach to developing polymers is time-intensive, costly, and often inefficient. Artificial Intelligence (AI) is emerging as a game-changer, transforming the way researchers and manufacturers design, develop, and produce polymers. By leveraging AI, the field of custom polymer synthesis is experiencing enhanced precision, speed, and scalability.

ResolveMass Laboratories Inc. is at the forefront of leveraging artificial intelligence (AI) to revolutionize custom polymer synthesis. By integrating advanced AI algorithms and machine learning models in Polymer Chemistry, ResolveMass accelerates the design and optimization of polymers with tailored properties for specific applications, such as drug delivery, sustainability, and advanced materials. AI enables the prediction of polymer behavior, optimization of synthesis pathways, and identification of novel monomers, significantly reducing development time and costs. This innovative approach ensures precision, scalability, and sustainability, positioning ResolveMass as a leader in next-generation polymer science.

Explainer Video – AI in Custom Polymer Synthesis

AI-Driven Polymer Lifecycle Assessment

AI is increasingly being applied to evaluate the entire lifecycle of polymeric materials, providing insights that guide both design and sustainability decisions. Through advanced data modeling, researchers can estimate environmental impacts—including carbon footprint, degradation rate, and recyclability—long before the material is produced. This proactive approach ensures that polymer development aligns with global sustainability targets and regulatory requirements.

In addition, lifecycle assessment models supported by AI enable manufacturers to identify inefficiencies across production, usage, and disposal stages. By predicting points of resource waste or performance degradation, companies can redesign polymer systems to be more durable, efficient, and environmentally responsible. This creates a closed-loop approach where polymers are engineered not only for performance but also for end-of-life recovery.

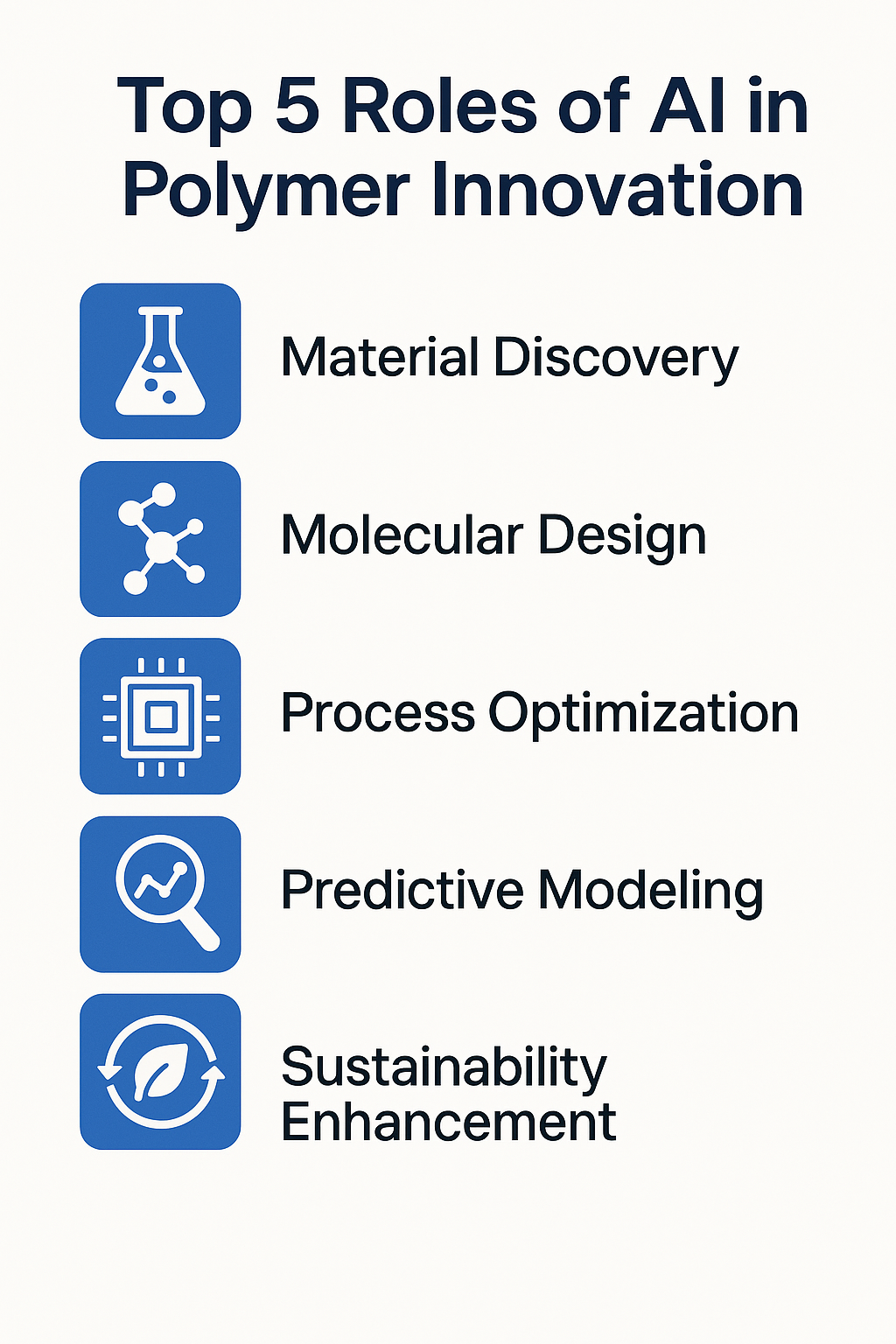

The Role of AI in Custom Polymer Synthesis

AI plays a pivotal role in overcoming challenges in polymer synthesis through:

1. Accelerating Material Discovery

AI algorithms can rapidly screen and predict the properties of countless polymer combinations, significantly speeding up the discovery of new materials.

- Example: Deep learning models predict polymer properties like thermal stability and tensile strength before synthesis.

- Impact: Reduces the time needed for experimental trials by narrowing down optimal candidates.

Explore how custom monomer selection boosts the performance and potential of polymers Monomer Selection Strategies for Custom Polymer Synthesis

2. Optimizing Polymer Design

By analyzing data from previous experiments, AI can suggest optimal synthesis routes, reaction conditions, and catalysts. This optimization leads to higher yields, reduced waste, and more sustainable manufacturing processes.

- Application: Designing biodegradable polymers for medical implants or high-strength polymers for aerospace.

- Tools: Generative adversarial networks (GANs) create virtual libraries of polymer structures with desired attributes.

Biodegradable materials are at the forefront of design innovation – see what’s the Emerging Trends in Custom Polymer Synthesis for 2025 and Beyond

3. Personalized Polymer Design

In applications like drug delivery, AI enables the design of polymers tailored to individual patient needs, ensuring better compatibility and efficacy. Custom polymers can be engineered to release drugs at controlled rates, target specific tissues, or degrade safely within the body.

Complex polymer design demands innovative inputs – deuterated polymers are leading the way. See how – Deuterated Polymers: A Cornerstone Guide to Synthesis, Applications, and Future Trends

4. Quality Control and Predictive Maintenance

These AI systems can monitor production processes in real-time, detecting anomalies and predicting equipment maintenance needs. So it works as a proactive approach to ensures consistent product quality and reduces downtime.

AI is turning barriers into breakthroughs – learn the top polymer synthesis challenges being tackled today 👉 Top Challenges and Opportunities in Custom Polymer Syntheis

AI-Augmented Catalyst Discovery

Catalysts play a central role in polymer synthesis, influencing reaction rates, polymer architecture, and final material performance. AI-driven catalyst discovery models allow chemists to explore vast chemical spaces, identifying catalyst candidates that may not have been evident through traditional experimentation. These models use pattern recognition and structure–function mapping to correlate catalyst features with expected polymer outcomes, thereby reducing the dependency on empirical testing.

With the integration of AI, researchers can also evaluate catalyst stability, toxicity, and cost-effectiveness before laboratory testing. This holistic evaluation accelerates the transition from conceptual catalyst design to industrial application. As the polymer industry pushes toward more efficient and greener processes, AI-guided catalyst development becomes indispensable in achieving controlled polymerization with minimal environmental impact.

AI Techniques Transforming Polymer Synthesis

1. Predictive Modeling and Simulation

AI algorithms, particularly machine learning models, can predict the properties of polymers based on their chemical structure and composition. This predictive capability allows researchers to design polymers with desired properties even before synthesis, saving time and resources by focusing efforts on promising candidates.

Chemical structure plays a defining role in material prediction – see the difference in polymer types here – Thermoplastic vs. Thermosetting Polymers: Insights for Custom Polymer Synthesis

2. Inverse Design for Tailored Properties

Inverse design involves specifying desired polymer properties and using AI to identify the molecular structures that would exhibit those properties. For instance, researchers have utilized AI-guided inverse design to discover recyclable vitrimeric polymers with specific glass transition temperatures, demonstrating the potential of AI in creating sustainable materials with tailored functionalities.

3. Process Optimization and Automation

AI can optimize polymer synthesis processes by analyzing large datasets of experimental results to identify optimal reaction conditions. This includes parameters such as temperature, pressure, and reactant concentrations. Moreover, AI-driven automation can enhance consistency and control over production lines, leading to higher yields and reduced waste.

4. Quality Control and Defect Detection

AI enhances quality assurance systems by integrating image processing and advanced analytics. Through machine vision technology, AI algorithms can identify discrepancies not visible to the human eye, allowing for real-time defect detection during production. This ensures consistency, reliability, and adherence to quality standards.

5. Sustainable Polymer Development

AI plays a crucial role in developing sustainable polymers by enabling the rational design of biodegradable materials and optimizing recycling strategies. By analyzing data on polymer degradation in different environments, AI can help design polymers that are more environmentally friendly and contribute to a circular polymer economy.

Explore the core polymerization methods that AI is now revolutionizing A Comprehensive Guide to Polymerization Techniques: Step-Growth vs Chain-Growth

Human–AI Collaboration in Polymer Research

While AI brings powerful computational capabilities, human expertise remains essential in interpreting results, validating predictions, and refining experimental approaches. Chemists and materials scientists provide the domain knowledge needed to guide AI models, ensuring that computational outputs align with real-world polymer chemistry principles. This collaboration accelerates innovation while maintaining scientific rigor.

Furthermore, AI systems benefit significantly from expert feedback, creating a continuous improvement loop. As researchers validate results and input new data, AI models evolve to become more accurate and versatile. This synergy ensures that polymer science advances through both computational intelligence and human creativity, leading to groundbreaking materials that may not emerge from either discipline alone.

Applications of AI in Custom Polymer Synthesis

1. Drug Delivery Systems

AI designs polymers with controlled-release mechanisms, improving the efficacy of pharmaceuticals.

- Case Study: Using AI, researchers developed a PEGylated polymer matrix for a cancer drug, optimizing its solubility and bioavailability.

2. Sustainable Polymers

AI aids in designing biodegradable and recyclable polymers to replace petroleum-based plastics.

- Example: Identifying plant-based monomers that offer durability comparable to conventional polymers.

Sustainable polymers start with smart monomer choices – explore effective selection strategies here – Monomer Selection Strategies for Custom Polymer Synthesis

3. Advanced Electronics

Polymers with unique electrical and thermal properties are critical for flexible electronics and semiconductors. AI identifies material combinations to meet these requirements.

- Example: Designing conductive polymers for high-performance batteries.

4. Biomedical Applications

AI customizes biocompatible polymers for tissue engineering and prosthetics.

- Impact: Enhanced patient outcomes with tailored polymer solutions.

See the real applications of polymer synthesis in modern science here 👉 The Importance of Polymer Synthesis in Modern Science and Technology

AI in Polymer Testing and Characterization

Polymer characterization traditionally relies on techniques like NMR, GPC, DSC, and FTIR, which generate complex datasets requiring expert interpretation. AI is now streamlining this process by automating spectral analysis, identifying patterns, and detecting anomalies with exceptional precision. These tools accelerate the validation of polymer structure and performance, significantly reducing analytical bottlenecks.

AI-powered characterization platforms also enable real-time decision-making during synthesis. By integrating sensor data and predictive analytics, engineers can adjust reaction parameters on the fly, preventing material defects and improving yield. This fusion of AI and analytical chemistry ensures that polymer development becomes both faster and more dependable.

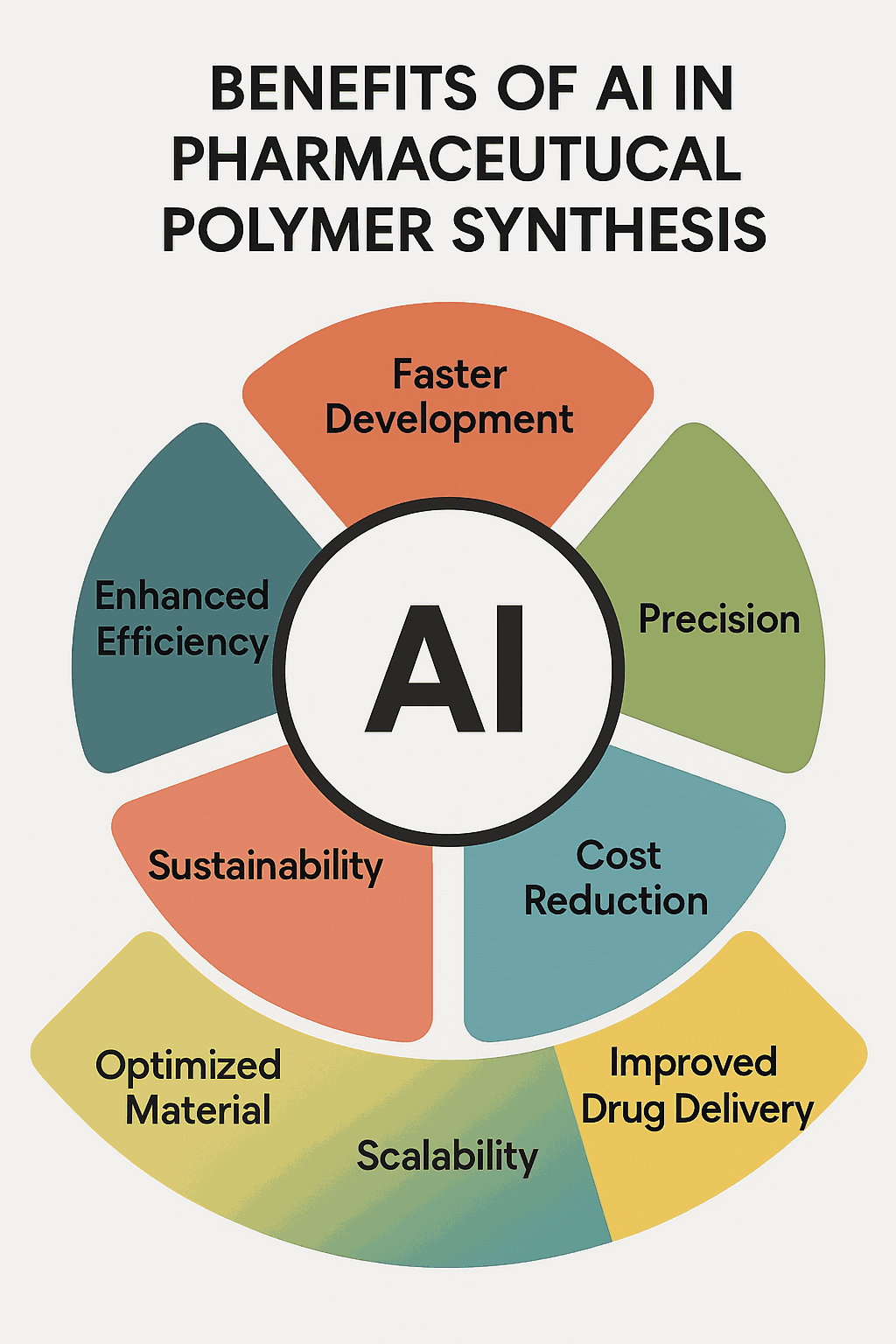

Benefits of AI Integration in Polymer Synthesis

1. Speed and Efficiency

AI dramatically reduces the time required for R&D by automating repetitive tasks and optimizing synthesis pathways.

2. Cost Reduction

Efficient resource utilization and minimized experimental failures lower overall development costs.

3. Enhanced Precision

AI ensures polymers meet exact specifications, reducing variability and improving reliability.

4. Sustainability

By optimizing reactions and minimizing waste, AI supports greener polymer synthesis practices.

Discover how different polymerization methods influence AI-driven synthesis outcomes – RAFT vs. ATRP: Choosing the Best Method for Custom Polymer Synthesis

Challenges in AI-Driven Polymer Synthesis

1. Data Availability and Quality

AI models rely on extensive, high-quality datasets. However, data on certain polymerization techniques and properties are limited.

2. Computational Complexity

Simulating large polymer systems at an atomic level requires significant computational power.

3. Integration into Traditional Workflows

Adopting AI tools requires training and adaptation, which can be a barrier for traditional labs.

See what challenges come up while creating custom polymers 👉 Top Challenges and Opportunities in Custom Polymer Synthesis

Future Opportunities

1. Autonomous Laboratories

Combining AI with robotics could lead to fully automated polymer synthesis labs, accelerating innovation.

2. Personalized Polymers

AI could enable on-demand synthesis of polymers tailored to individual requirements, such as patient-specific drug delivery systems.

3. Collaborative AI Models

AI systems that integrate insights from various industries (e.g., healthcare, energy) could uncover new polymer applications.

Discover what the future holds for AI in polymer design through global industry forecasts here Global Market Insights: The Future of Custom Polymer Synthesis

Conclusion

AI is revolutionizing the field of custom polymer synthesis by enabling faster material discovery, optimizing polymer design, and reducing environmental impact. The synergy of AI and polymer science opens doors to innovative applications, from sustainable materials to advanced biomedical devices.

High purity leads to high performance – explore how to achieve it in custom synthesis here 👉 How to Ensure High Purity in Custom Polymer Synthesis

- Explore our Custom Polymer Synthesis Services.

- Learn more about our expertise in Material Characterization.

- Contact us for innovative solutions at our Contact Us page.

ResolveMass Laboratories Inc.: Your Trusted Partner in Polymer Synthesis and Characterization

ResolveMass Laboratories Inc. is a leading contract research organization in Canada, recognized for its excellence in custom polymer synthesis and advanced polymer characterization. With over a decade of experience, we have successfully delivered high-performance polymer solutions for applications in pharmaceuticals, biotechnology, medical devices, and advanced materials. Our multidisciplinary team of polymer chemists and materials scientists holds extensive expertise in designing, synthesizing, and characterizing complex polymer systems—including block copolymers, functionalized bioconjugates, and PEGylated compounds.

What sets us apart is our ability to provide end-to-end support—from molecular design and synthesis to structural validation using techniques like NMR, GPC, MALDI-TOF, DSC, TGA, LCMS, GCMS, and FTIR. Whether you require custom polymers for research or GMP-grade materials for product development, we tailor every project to your specifications while ensuring regulatory compliance and quality assurance.

Clients across North America trust ResolveMass for our scientific rigor, transparency, and commitment to delivering reproducible results. Partner with ResolveMass Laboratories for polymer synthesis and characterization—where innovation meets dependability.

FAQs on Custom Polymer Synthesis

AI accelerates the discovery of new polymers by rapidly analyzing vast chemical spaces and predicting material properties before any laboratory synthesis. Machine learning models can learn from existing polymer data to suggest combinations with desired thermal, mechanical, or chemical performance characteristics. This reduces the need for time-consuming trial-and-error experimentation. As a result, researchers can focus their lab efforts on the most promising candidates, increasing efficiency and innovation.

Yes — AI enhances process efficiency by identifying optimal reaction conditions such as temperature, pressure, and catalyst types based on patterns in historical experimental data. These optimizations reduce waste, improve yield, and shorten production timelines. AI can also automate routine tasks and continuously adjust parameters in real time to maintain quality. This leads to smarter, more sustainable manufacturing workflows with less manual intervention.

AI-based quality control systems use advanced analytics and machine vision to detect defects that might be missed by human inspection. By processing sensor and imaging data in real time, these systems can flag anomalies or deviations early in production. This improves reliability, reduces material scrap, and ensures consistent performance of final products. Additionally, predictive maintenance powered by AI can anticipate equipment issues before they lead to downtime.

A significant challenge is the availability of high-quality, standardized data, which is essential for training effective AI models but often limited in the polymer field due to complex structures and synthesis routes. There are also issues related to the interpretability of AI predictions, as many advanced models act as “black boxes” without clear reasoning paths. Finally, the computational cost of simulating large polymer systems can be high, requiring powerful hardware and efficient algorithms.

Absolutely — AI can evaluate the environmental impacts of polymer life cycles and help design materials that degrade more easily or are fully recyclable. By predicting degradation behavior and suggesting greener monomers or synthesis pathways, AI supports the creation of environmentally responsible polymers. This contributes to reducing plastic waste and supports circular economy goals. Additionally, optimized manufacturing processes minimize energy use and emissions.

AI models, especially those based on machine learning, can correlate molecular structure with polymer performance traits like tensile strength, thermal stability, and flexibility. These predictive insights allow scientists to estimate how a polymer will behave before synthesis, saving research time and material resources. Advanced models even incorporate chemical language understanding to interpret complex polymer patterns. This capability enables smarter material engineering and discovery.

Yes — while AI can process data and suggest designs, human chemists and materials scientists remain essential for interpreting results, validating predictions, and designing practical experiments. Expert judgment is crucial for setting research objectives, evaluating AI outputs in context, and integrating insights into real-world applications. The best outcomes come from collaborative human–AI workflows where each complements the other’s strengths.

Ready to Get Started?

📩 Contact our expert team

📞 Request a quote for method development

📅 Book a consultation with our scientists

🧪 Submit your sample for testing

References

- Pyzer-Knapp, E.O., Pitera, J.W., Staar, P.W.J. et al. Accelerating materials discovery using artificial intelligence, high performance computing and robotics. npj Comput Mater 8, 84 (2022). https://doi.org/10.1038/s41524-022-00765-z

- Smith, R., et al. “Generative Models in Custom Polymer Design.” Journal of Polymer Science, 2022. DOI: 10.1016/j.polymer.2022.08.015

- Kim, J., et al. “Machine Learning for Sustainable Polymer Solutions.” ACS Sustainable Chemistry & Engineering, 2023. DOI: 10.1021/sc6001256

Bioanalytical Services FAQs

Bioanalytical Services FAQs – Comprehensive Guide for Pharma & Biotech Bioanalytical services play a critical…

Drug Discovery Services – FAQs

Drug Discovery Services – FAQs: Introduction Drug discovery is a complex, multi-stage process that transforms…

When Should You Start NDA-Ready Chemistry, Manufacturing, and Controls (CMC) Development?

✅ Summary of the Article Start NDA-Ready CMC Development as early as Preclinical Phase, with…

Advanced Bioanalytical Strategies for Complex Drug Modalities

Introduction Advanced Bioanalytical Strategies have become a critical enabler in modern drug development as pharmaceutical…

Bioanalytical Challenges in Antibody Drug Conjugates and Protein Degrader Programs

Introduction The biopharmaceutical landscape has witnessed remarkable innovation, with Antibody Drug Conjugate bioanalytical services becoming…

LC-MS Bioanalysis for Oligonucleotides and RNA-Based Therapeutics

Introduction LC-MS bioanalysis for oligonucleotides has emerged as the cornerstone analytical technique supporting the rapid…

🧠 How to Build a Predictive AI Pipeline for Custom Polymer Synthesis in Pharma

To move beyond theoretical use and truly integrate AI into pharma polymer R&D, a predictive pipeline is essential. Here’s a step-by-step framework to build one:

⚙️ Step 1: Digitalize Your Lab Workflow

Start by converting wet-lab experiments into structured digital formats.

Actions:

- Record all formulation inputs: monomer types, ratios, solvents, temperature, stirring time, pH, etc.

- Track outputs: yield, viscosity, particle size, zeta potential, drug entrapment, etc.

Tools: ELN (Electronic Lab Notebook), LIMS (Laboratory Information Management System)

📊 Step 2: Build a Centralized Polymer-Drug Dataset

Instead of fragmented spreadsheets, create a relational dataset linking:

- Polymer types and characteristics

- Drug physicochemical properties (logP, solubility, pKa)

- Performance outcomes (release profile, bioavailability, stability)

This dataset is your foundation for ML model training.

🔍 Step 3: Select the Right AI Algorithm

Choose your model based on the goal:

| Objective | Suggested AI Method |

|---|---|

| Predict drug release | Random Forest, XGBoost |

| Optimize polymer ratio | Bayesian Optimization |

| Simulate particle size behavior | Neural Networks, SVR |

| Select polymers for stability | Decision Trees, Ensemble |

🧪 Step 4: Validate with Retrospective Studies

Before using AI for new predictions, test it with previously completed projects.

✅ Ask: Can it correctly predict the results of polymer-drug systems you’ve already tested?

This builds confidence and internal validation.

🔁 Step 5: Link AI Output to Experimental Decision-Making

Make the AI model actionable:

- Auto-suggest next best polymer-monomer pair

- Predict ideal surfactant or stabilizer concentration

- Recommend experimental batches likely to succeed (above threshold)

Example Output: “Use 70:30 PCL:PEG with 0.2% Pluronic F127 to achieve sustained release > 12h.”

🔐 Step 6: Integrate Regulatory Intelligence

For pharma, link your pipeline to ICH, FDA, and EMA guidelines.

Add modules for:

- Biodegradability prediction (as per FDA polymer guidance)

- Extractables/leachables risk from excipient-polymer blends

- Toxicity risk modeling via QSAR

🚀 Step 7: Expand for Cross-Functional Use

Make the pipeline usable across departments:

- Formulation: For polymer screening

- Quality: For stability projections

- Tech Transfer: For scale-up simulation

- Regulatory: For dossier-ready data outputs