Gel Permeation Chromatography (GPC) is a crucial analytical technique used to determine the molecular weight distribution of polymers, including biodegradable polyesters like Poly Lactide (PLA), Poly(Lactide-co-Glycolide) (PLGA), and Polycaprolactone (PCL). As biodegradable polymers gain traction in medical, pharmaceutical, and industrial applications, accurate characterization of their molecular properties is vital. This blog delves into the significance of GPC analysis, its role in evaluating PLA, PLGA, and PCL, and how the method ensures polymer consistency and quality.

🔍 Article Highlights

- Explains the fundamentals of Gel Permeation Chromatography (GPC) and why it is essential for analyzing biodegradable polymers such as PLA, PLGA, and PCL.

- Describes how molecular weight parameters (Mn, Mw, and PDI) influence polymer performance, degradation behavior, and application suitability.

- Demonstrates the role of GPC in monitoring polymer degradation kinetics, especially for biomedical and drug delivery applications.

- Outlines GPC methodology, including sample preparation, instrumentation, calibration approaches, and data interpretation.

- Highlights how molecular weight distribution impacts functional performance in medical devices, pharmaceuticals, 3D printing, and packaging.

- Discusses regulatory expectations, analytical challenges, and recent advancements in GPC technology for high-quality polymer characterization.

Understanding GPC and Its Importance

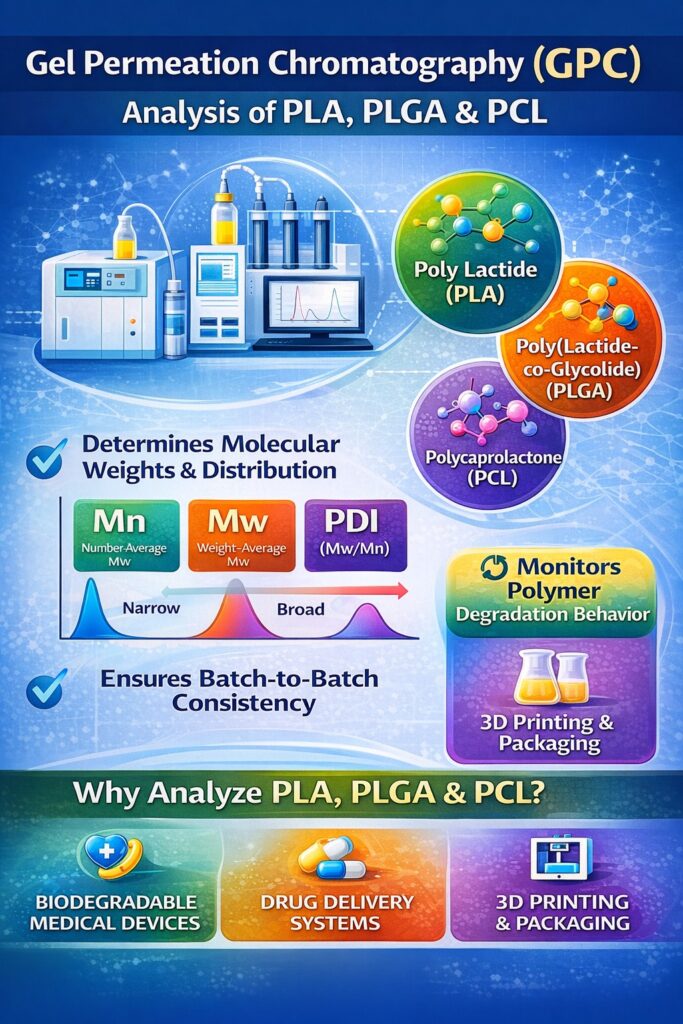

GPC, also known as Size Exclusion Chromatography (SEC), is a technique used to separate and analyze macromolecules based on their hydrodynamic volume rather than their chemical properties. The primary goal of Gel Permeation Chromatography (GPC) analysis is to determine:

- Number-average molecular weight (Mn)

- Weight-average molecular weight (Mw)

- Polydispersity index (PDI)

- Molecular weight distribution

Role of GPC in Monitoring Polymer Degradation Kinetics

Understanding how biodegradable polymers degrade over time is essential for both research and application development. GPC is widely used to monitor degradation kinetics by tracking changes in molecular weight distribution as polymers are exposed to moisture, heat, or physiological conditions. By periodically analyzing samples, researchers can observe chain scission events and quantify molecular weight reduction, which directly reflects polymer breakdown mechanisms.

This information is particularly valuable in biomedical research, where degradation behavior influences mechanical stability, drug release, and biocompatibility. For specialized applications, GPC analysis for drug delivery polymers allows scientists to correlate degradation rates with material performance, ensuring that materials degrade as intended throughout their functional lifespan. GPC enables scientists to correlate degradation rates with material performance, allowing more accurate prediction of in-use behavior. These insights support informed polymer selection and help ensure that materials degrade as intended throughout their functional lifespan.

Why GPC for PLA, PLGA, and PCL?

GPC is particularly effective for analyzing PLA, PLGA, and PCL due to:

- High precision in molecular weight determination

- Capability to detect polymer degradation

- Understanding batch-to-batch consistency

- Assessing polymer suitability for biomedical and pharmaceutical applications

Structure and Properties of PLA, PLGA, and PCL

Before diving into GPC analysis, it is essential to understand the fundamental differences between these three biodegradable polymers.

Poly Lactide (PLA)

PLA is a biodegradable, thermoplastic polyester derived from renewable resources such as corn starch and sugarcane. It exhibits:

- High mechanical strength and stiffness

- Good biocompatibility

- Slow degradation rate

- Applications in 3D printing, medical implants, and packaging

Poly(Lactide-co-Glycolide) (PLGA)

PLGA is a copolymer of lactic acid and glycolic acid, widely used in drug delivery systems due to its tunable degradation rate, which depends on the lactic-to-glycolic ratio.

- Faster degradation compared to PLA

- Excellent biocompatibility

- Used in drug delivery microspheres and biodegradable sutures

Polycaprolactone (PCL)

PCL is a semicrystalline biodegradable polyester with a low melting point (~60°C) and is extensively used in tissue engineering and controlled drug release.

- Lower mechanical strength than PLA and PLGA

- Slower degradation rate (~2-4 years)

- Good flexibility and biocompatibility

GPC Analysis of PLA, PLGA, and PCL: Methodology

Sample Preparation

To obtain accurate results, polymer samples must be properly prepared before GPC analysis. This involves:

- Dissolution: PLA, PLGA, and PCL are dissolved in suitable solvents like tetrahydrofuran (THF) or chloroform.

- Filtration: Filtering through a 0.2 µm membrane to remove undissolved particles.

- Injection: Introduction of the polymer solution into the GPC system.

Need a protocol? Check our comprehensive GPC sample preparation guide for best practices to avoid common errors.

Instrumentation and Calibration

A standard GPC setup includes:

- Pump: Ensures constant solvent flow.

- Injector: Introduces the polymer solution into the column.

- Columns: Packed with porous beads to separate polymers by molecular size.

- Detector: Refractive index (RI) or UV detector to analyze molecular weight distribution.

- Data System: Converts detector signals into molecular weight data.

To understand the mathematical approach behind these results, explore the different methods of measuring polymer molecular weight by GPC.

Complementary Analytical Techniques Supporting GPC Findings

Although GPC is the primary technique for determining molecular weight distribution, it is often used alongside complementary analytical methods to build a complete polymer characterization profile. Techniques such as Differential Scanning Calorimetry (DSC), Nuclear Magnetic Resonance (NMR), and Fourier Transform Infrared Spectroscopy (FTIR) provide additional insight into thermal properties, chemical composition, and functional group integrity.

By integrating GPC results with data from these methods, researchers can confirm structural changes and validate analytical conclusions. For example, molecular weight shifts observed in GPC may correspond to crystallinity changes detected by DSC. This multi-technique approach strengthens data reliability and reduces the risk of misinterpretation, especially in regulated research environments.

Calibration Methods

GPC calibration is essential for accurate molecular weight determination. Two common methods are:

- Universal Calibration: Uses polystyrene standards and Mark-Houwink equations to calculate molecular weight.

- Conventional Calibration: Uses polymer-specific standards for direct comparison.

Data Interpretation

The molecular weight parameters derived from GPC include:

- Mn (Number-Average Molecular Weight): Sum of individual polymer molecule weights divided by the number of molecules.

- Mw (Weight-Average Molecular Weight): Reflects the weight contribution of each polymer molecule.

- PDI (Polydispersity Index, Mw/Mn): Indicates molecular weight distribution (PDI = 1 for monodisperse polymers; higher PDI values suggest broader distributions).

Influence of Molecular Weight Distribution on Functional Performance

Molecular weight distribution plays a critical role in determining the physical and functional properties of biodegradable polymers. While average molecular weight values such as Mn and Mw provide useful benchmarks, the overall distribution reveals how uniformly polymer chains are formed. GPC helps identify whether a polymer batch contains a narrow or broad range of chain lengths, which can significantly affect performance outcomes.

For applications such as drug delivery systems or implantable devices, variations in molecular weight distribution can lead to inconsistent degradation and unpredictable behavior. Utilizing high-resolution GPC molecular weight analysis acts as a key decision-making tool during formulation optimization and material qualification. A broad distribution may result in uneven erosion, while a narrow distribution often promotes more controlled and reproducible performance. GPC data therefore acts as a key decision-making tool during formulation optimization and material qualification.

Applications of GPC Analysis in PLA, PLGA, and PCL

Biodegradable Medical Devices

GPC helps evaluate the molecular weight and degradation behavior of medical implants, stents, and scaffolds, ensuring performance consistency.

Pharmaceutical Formulations

PLGA and PCL are extensively used in drug delivery systems. GPC verifies polymer integrity, ensuring controlled drug release kinetics.

3D Printing and Packaging

PLA is a primary material in 3D printing and sustainable packaging. GPC ensures material consistency and mechanical performance.

Regulatory and Quality Expectations for GPC in Biomedical Polymers

In regulated biomedical and pharmaceutical applications, GPC data plays a vital role in demonstrating polymer consistency and quality. Regulatory authorities expect validated analytical methods with well-defined calibration procedures, system suitability criteria, and reproducibility. Molecular weight data generated by GPC is often included in technical dossiers to support material characterization and stability claims.

Quality control laboratories rely on GPC to monitor batch-to-batch variability and detect early signs of polymer degradation during storage or processing. Consistent molecular weight profiles help ensure that products meet predefined specifications and perform reliably in their intended use. As a result, GPC serves not only as a research tool but also as a cornerstone of quality assurance programs.

Challenges and Solutions in GPC Analysis of PLA, PLGA, and PCL

Common Challenges

- Solubility Issues: Not all solvents are suitable for these polymers.

- Degradation During Analysis: Heat and solvent exposure can degrade polymers.

- Peak Broadening: Due to improper calibration.

Solutions

- Use optimized solvents (e.g., THF for PLA, PLGA, and PCL).

- Minimize exposure to heat and moisture.

- Use high-resolution columns for precise separation.

Advancements in GPC Technology for Biodegradable Polymer Analysis

Recent advancements in GPC technology have significantly enhanced the analysis of biodegradable polymers such as PLA, PLGA, and PCL. Modern systems now incorporate multi-detector setups, including light scattering and viscometry, which enable absolute molecular weight determination without complete reliance on calibration standards. These improvements are particularly beneficial for copolymers where hydrodynamic behavior may vary.

In addition, enhanced column chemistries and advanced data-processing software have improved resolution and analytical accuracy. Faster run times and improved sensitivity allow researchers to analyze complex polymer systems more efficiently. These technological developments continue to expand the role of GPC in cutting-edge polymer research and industrial quality control.

Expert Tip: Selecting the right hardware is half the battle. Read our guide on GPC column and detector selection to optimize your setup for PLA and PLGA analysis.

Conclusion

GPC analysis is an indispensable tool for characterizing PLA, PLGA, and PCL, ensuring these biodegradable polymers meet industry standards for biomedical and industrial applications. With precise molecular weight determination and polymer profiling, GPC plays a pivotal role in advancing sustainable materials and innovative healthcare solutions.

Frequently Asked Questions

GPC solvents are selected based on the solubility and chemical stability of the polymer being analyzed. Common organic solvents include tetrahydrofuran (THF), chloroform, dimethylformamide (DMF), and toluene, while aqueous GPC uses water or buffered solutions. The solvent must fully dissolve the polymer, be compatible with the column, and maintain a stable flow during analysis.

GPC commonly uses refractive index (RI) detectors due to their broad compatibility with most polymers. UV detectors are employed when polymers contain UV-active groups, while light scattering and viscometer detectors provide absolute molecular weight and structural information. Multi-detector systems enhance accuracy by combining complementary detection principles.

GPC columns are packed with porous polymeric or silica-based materials designed to separate molecules by size. Columns vary in pore size to accommodate different molecular weight ranges and are often connected in series for improved resolution. Specialty columns are available for organic, aqueous, and high-temperature GPC applications.

Universal calibration is a GPC approach that correlates elution volume with the product of intrinsic viscosity and molecular weight. It relies on the principle that polymers with the same hydrodynamic volume elute at the same time, regardless of chemical composition. This method allows accurate molecular weight determination using standard polymers and viscosity data.

GPC provides detailed molecular weight distribution data without chemically altering the sample. It offers high reproducibility, minimal sample preparation, and compatibility with a wide range of polymers. The technique is widely used for quality control, degradation studies, and research due to its reliability and non-destructive nature.

Reference

- Balaiah, S., Shyamala, K., Swapna, K., Srikanth Sandesh, J., & Sharma, J. V. C. (2021). A review on gel permeation chromatography and its pharmaceutical applications. International Journal of Pharmaceutical Research and Applications, 6(1), 604–610. Retrieved from https://ijprajournal.com/issue_dcp/A%20Review%20on%20Gel%Permeation%20Chromatography%20and%20Its%20Pharmaceutical%20Applications.pdf

- Balke, S. T. (1969). Gel permeation chromatography. Industrial & Engineering Chemistry Product Research and Development, 8(1), 6–12. https://doi.org/10.1021/i360029a008

QUICK ENQUIRY

When Should You Start NDA-Ready Chemistry, Manufacturing, and Controls (CMC) Development?

✅ Summary of the Article Start NDA-Ready CMC Development as early as Preclinical Phase, with…

Advanced Bioanalytical Strategies for Complex Drug Modalities

Introduction Advanced Bioanalytical Strategies have become a critical enabler in modern drug development as pharmaceutical…

Bioanalytical Challenges in Antibody Drug Conjugates and Protein Degrader Programs

Introduction The biopharmaceutical landscape has witnessed remarkable innovation, with Antibody Drug Conjugate bioanalytical services becoming…

LC-MS Bioanalysis for Oligonucleotides and RNA-Based Therapeutics

Introduction LC-MS bioanalysis for oligonucleotides has emerged as the cornerstone analytical technique supporting the rapid…

Chemistry, Manufacturing, and Controls (CMC) Services for Small Molecules vs Peptides vs Oligonucleotides

Summary: Key Takeaways at a Glance CMC Services for Peptides require specialized analytical, manufacturing, and…

Drug Substance vs Drug Product Chemistry, Manufacturing, and Controls (CMC) : IND and NDA Perspectives

✅ Summary: Drug Substance vs Drug Product CMC – IND and NDA Perspectives CMC for…