Poly(L-lactide) (PLLA) | CAS Number: 26161-42-2

Overview

Poly(L-lactide) (PLLA), CAS Number 26161-42-2, is a high-performance, biodegradable, and biocompatible aliphatic polyester derived from renewable resources such as corn starch or sugarcane. As one of the most extensively studied members of the polylactide family, PLLA has become a benchmark polymer in biomedical engineering, controlled drug delivery, and sustainable materials.

Owing to its semi-crystalline structure, excellent mechanical strength, and tunable degradation behavior, PLLA serves as a versatile material for applications ranging from bioabsorbable sutures and tissue scaffolds to bioplastic packaging and pharmaceutical excipients. Its ability to degrade into naturally metabolizable L-lactic acid makes it an environmentally friendly and physiologically compatible polymer.

Chemical Structure and Composition

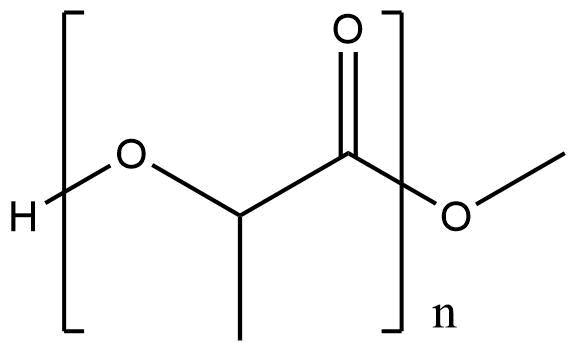

Poly(L-lactide) is a homopolymer of the optically pure L-isomer of lactic acid. It is synthesized through the ring-opening polymerization (ROP) of L-lactide, a cyclic dimer of L-lactic acid, resulting in the following repeating structure:

[–O–CH(CH₃)–CO–]_n

Key structural attributes include:

-

Chirality: Derived exclusively from L-lactic acid, PLLA exhibits a regular, isotactic configuration that promotes crystallinity.

-

Crystallinity: Typically ranges between 30–40%, influencing its mechanical strength and degradation rate.

-

Glass Transition Temperature (Tg): ~55–65°C

-

Melting Temperature (Tm): ~170–180°C

The stereoregular nature of PLLA gives it superior tensile strength, stiffness, and thermal stability compared to its racemic (PDLLA) counterpart.

Synthesis of Poly(L-lactide)

PLLA is commonly synthesized via catalytic ring-opening polymerization (ROP) of L-lactide using metal-based catalysts such as stannous octoate (Sn(Oct)₂) under inert and anhydrous conditions.

Typical Synthesis Conditions

-

Monomer: L-lactide

-

Catalyst: Sn(Oct)₂ or zinc lactate

-

Temperature: 120–180°C

-

Reaction Time: 8–24 hours

-

Atmosphere: Inert gas (nitrogen or argon)

The polymerization proceeds through a coordination–insertion mechanism, producing high-molecular-weight PLLA with controlled polydispersity. Subsequent precipitation and solvent extraction steps ensure the removal of unreacted monomers and catalysts, resulting in high-purity, medical-grade polymer.

Physicochemical Properties

| Property | Description |

|---|---|

| Chemical Name | Poly(L-lactide) |

| CAS Number | 26161-42-2 |

| Molecular Formula | (C₃H₄O₂)_n |

| Appearance | White or off-white solid/granules |

| Molecular Weight (Mw) | 10,000 – 300,000 g/mol (customizable) |

| Glass Transition Temperature (Tg) | 55–65°C |

| Melting Temperature (Tm) | 170–180°C |

| Crystallinity | 30–40% (depends on processing history) |

| Solubility | Soluble in chloroform, dichloromethane, and dioxane; insoluble in water |

| Degradation Products | L-lactic acid (metabolically benign) |

| Biodegradability | Complete hydrolytic degradation via ester bond cleavage |

Degradation Behavior

PLLA undergoes hydrolytic degradation through the cleavage of ester linkages in the polymer backbone. The degradation process involves two main stages:

-

Bulk Hydrolysis: Random scission of ester bonds leads to a reduction in molecular weight.

-

Surface Erosion and Bioabsorption: The low-molecular-weight oligomers are metabolized into L-lactic acid, which enters the Krebs cycle and is eventually converted into CO₂ and water.

The degradation rate depends on several factors:

-

Crystallinity: Higher crystallinity → slower degradation.

-

Molecular weight: Lower Mw → faster hydrolysis.

-

Environmental factors: Temperature, pH, and moisture accelerate degradation.

Typically, PLLA takes several months to years to completely degrade under physiological conditions, which is ideal for long-term biomedical implants and scaffolds.

Applications

1. Biomedical and Pharmaceutical Applications

-

Absorbable Sutures and Implants: PLLA is widely used for resorbable surgical sutures, orthopedic pins, and fixation devices, offering excellent mechanical support during tissue healing.

-

Drug Delivery Systems: Employed as a biodegradable matrix for microspheres, nanocapsules, and implants, enabling controlled release of small molecules, peptides, and proteins.

-

Tissue Engineering: Its biocompatibility and mechanical strength make it suitable for scaffold fabrication to support cell growth and tissue regeneration.

-

Medical Device Coatings: PLLA is used as a drug-eluting stent coating, facilitating localized and time-controlled drug release.

2. Sustainable Materials and Packaging

PLLA is increasingly used in bioplastics and eco-friendly packaging materials due to its renewable origin and compostability. Its high clarity and rigidity make it a sustainable alternative to petroleum-based polymers such as PET.

3. Custom Polymer Development

At ResolveMass Laboratories Inc., Poly(L-lactide) can be customized for research or industrial use, with tunable molecular weights, end-group functionalization, and copolymer blends (e.g., with PGA or PEG) to achieve specific mechanical, degradation, and processing characteristics.

Quality Assurance and Characterization

ResolveMass Laboratories ensures each batch of Poly(L-lactide) (CAS 26161-42-2) meets rigorous analytical and quality control standards. Our in-house analytical team characterizes every polymer using:

-

Nuclear Magnetic Resonance (¹H and ¹³C NMR) for monomer purity and stereoregularity

-

Gel Permeation Chromatography (GPC) for molecular weight and distribution

-

Differential Scanning Calorimetry (DSC) for Tg and Tm

-

Thermogravimetric Analysis (TGA) for thermal stability

-

FTIR and HPLC for functional group confirmation and impurity analysis

All materials are produced under ISO 9001:2015-certified conditions, with full documentation including CoA, MSDS, and analytical reports available upon request.

Advantages

-

Biodegradable and biocompatible

-

Derived from renewable resources

-

Excellent mechanical strength and transparency

-

FDA-approved for multiple biomedical applications

-

Customizable molecular weight and crystallinity

-

Environmentally sustainable and recyclable

Conclusion

Poly(L-lactide) (PLLA, CAS 26161-42-2) represents the cornerstone of biodegradable polymer science. Combining excellent biocompatibility, mechanical integrity, and controlled degradability, PLLA has become indispensable in modern biomedical engineering, pharmaceutical formulation, and sustainable polymer applications.

At ResolveMass Laboratories Inc., we supply research-grade and GMP-grade PLLA tailored to your specific application needs — from custom synthesis and molecular weight optimization to analytical characterization for regulatory submissions and R&D projects.

Read below Learn with Us Articles:

PLGA Nanoparticles Synthesis: A Step-by-Step Guide for Beginners

PLGA 50:50 Poly(D L-lactide-co-glycolide) Supplier Guide: What to Look for in a Reliable Provider

The Science Behind GPC: A Deep Dive into Analyzing PLA, PLGA, and PCL for Research

Reviews

There are no reviews yet.