Poly(caprolactone) (PCL) | CAS No.: 24980-41-4

Overview

Poly(caprolactone) (PCL), CAS Number 24980-41-4, is a biodegradable aliphatic polyester widely recognized for its excellent biocompatibility, thermal stability, and processability. Synthesized by the ring-opening polymerization (ROP) of ε-caprolactone, PCL has become an essential material in drug delivery systems, tissue engineering scaffolds, resorbable sutures, and biodegradable packaging.

Due to its slow and predictable degradation rate, low melting temperature, and compatibility with other polymers, PCL serves as a versatile polymer for blending and copolymerization. It is frequently used as a soft segment in biodegradable copolymers such as PCL–PEG, PCL–PLA, and PCL–PLGA, which are engineered for tailored mechanical and degradation properties in biomedical and industrial applications.

Chemical Identity

| Property | Description |

|---|---|

| Chemical Name | Poly(ε-caprolactone) |

| CAS Number | 24980-41-4 |

| Synonyms | PCL; Polycaprolactone; Poly(ε-caprolactone); PCL polymer; PCL biodegradable polyester |

| Molecular Formula | (C₆H₁₀O₂)_n |

| Molecular Weight (Mw) | 10,000 – 100,000 g/mol (customizable) |

| Appearance | White or off-white granules, flakes, or powder |

| Glass Transition Temperature (Tg) | -60°C |

| Melting Temperature (Tm) | 58–64°C |

| Density | 1.1–1.2 g/cm³ |

| Solubility | Soluble in chloroform, dichloromethane, benzene, and toluene; insoluble in water |

| Biodegradation Products | 6-hydroxycaproic acid (non-toxic, metabolized via β-oxidation pathway) |

Structure and Synthesis

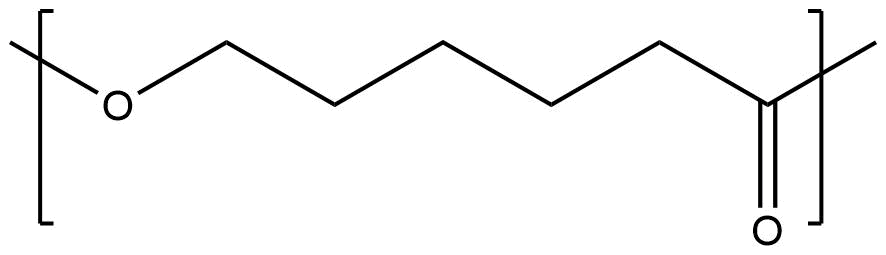

Poly(caprolactone) is a semi-crystalline polyester with repeating –[O–(CH₂)₅–CO]– units. It is typically synthesized by ring-opening polymerization (ROP) of ε-caprolactone using catalysts such as stannous octoate (Sn(Oct)₂), zinc lactate, or aluminum isopropoxide.

Typical Synthesis Route

-

Monomer: ε-caprolactone

-

Catalyst: Sn(Oct)₂ or similar organometallic catalysts

-

Temperature: 100–160°C

-

Reaction Type: Coordination–insertion mechanism

-

Atmosphere: Inert gas (argon or nitrogen)

This process yields PCL with narrow molecular weight distribution, excellent reproducibility, and adjustable polymer chain lengths depending on the desired end-use. Post-polymerization, the product is purified via precipitation and vacuum-dried to remove residual monomers and catalysts.

Physicochemical and Thermal Properties

PCL’s unique combination of low glass transition temperature (Tg) and moderate melting temperature (Tm) gives it exceptional flexibility and ductility, even at sub-zero temperatures. Its semi-crystalline morphology contributes to good tensile strength, while the long aliphatic chains confer hydrophobicity and stability.

Key attributes include:

-

Excellent melt processability — compatible with extrusion, injection molding, and electrospinning.

-

High flexibility — ideal for soft biomedical materials.

-

Slow degradation rate — extending utility in long-term implantable systems.

-

Compatibility — miscible or blendable with various natural and synthetic polymers (e.g., PLA, PEG, gelatin).

Degradation Behavior

PCL degrades primarily via hydrolytic cleavage of ester linkages in its backbone, producing 6-hydroxycaproic acid, which is further metabolized through the β-oxidation pathway in the body.

The degradation rate is slower than that of PLLA or PLGA, often extending over months to several years, depending on molecular weight, crystallinity, and environmental conditions.

Key factors influencing degradation:

-

Molecular weight: Lower Mw → faster degradation

-

Crystallinity: Higher crystallinity → slower hydrolysis

-

Environmental factors: Temperature, pH, and enzymatic activity

This slow and steady degradation makes PCL ideal for long-term drug delivery implants, bone fixation devices, and tissue scaffolds requiring sustained structural integrity.

Applications

1. Drug Delivery Systems

PCL is widely employed in controlled and sustained-release formulations, including microparticles, nanoparticles, and implants. Its hydrophobic nature slows drug diffusion, allowing long-term release profiles for hydrophobic drugs, hormones, and antibiotics.

2. Tissue Engineering and Regenerative Medicine

PCL serves as a biocompatible scaffold material for bone, cartilage, nerve, and skin tissue regeneration. Its mechanical flexibility, combined with biodegradability, supports cell adhesion, proliferation, and differentiation.

PCL can be electrospun into nanofibers or 3D printed into porous scaffolds, mimicking natural extracellular matrix (ECM) structures.

3. Biomedical Devices

Because of its elasticity and resorbability, PCL is used in resorbable sutures, wound dressings, and soft tissue implants.

It also acts as a polymer coating for drug-eluting medical devices, providing biocompatible surface modification and controlled degradation.

4. Copolymer and Blend Component

PCL is often combined with faster-degrading polymers such as PLA or PLGA to tailor degradation kinetics and mechanical properties. Copolymer systems like PCL–PEG–PCL are used to form thermoresponsive hydrogels and nanocarriers in drug delivery.

5. Industrial and Environmental Applications

Beyond biomedical use, PCL finds applications in biodegradable plastics, adhesives, and coatings. Its low melting point allows easy processing in conventional thermoplastic manufacturing. It is also used as a compatibilizer in polymer blends to enhance interfacial adhesion.

Quality and Characterization

At ResolveMass Laboratories Inc., we supply high-purity Poly(caprolactone) (CAS 24980-41-4) suitable for both research and GMP-compliant pharmaceutical applications.

Each batch is characterized using advanced analytical methods to ensure consistency, reproducibility, and purity.

Analytical Testing Capabilities:

-

Gel Permeation Chromatography (GPC) – for molecular weight distribution

-

NMR (¹H and ¹³C) – for structural confirmation and purity

-

Differential Scanning Calorimetry (DSC) – for thermal transitions (Tg, Tm)

-

Thermogravimetric Analysis (TGA) – for thermal stability

-

FTIR and HPLC – for functional group and residual monomer analysis

All products are manufactured under ISO 9001:2015-certified conditions and are accompanied by a Certificate of Analysis (CoA) and Material Safety Data Sheet (MSDS).

Advantages

-

Biocompatible and non-toxic degradation products

-

Excellent flexibility and toughness

-

Easy processing by extrusion and molding

-

Slow and predictable degradation

-

Compatible with a wide range of polymers

-

Applicable in both biomedical and industrial sectors

Conclusion

Poly(caprolactone) (PCL, CAS 24980-41-4) stands out as a highly versatile biodegradable polyester that bridges the gap between performance and sustainability. With its superior mechanical flexibility, tunable degradation, and outstanding biocompatibility, PCL continues to drive innovation in drug delivery, tissue engineering, and green polymer technology.

At ResolveMass Laboratories Inc., we provide custom-synthesized PCL in tailored molecular weights, end-functionalized variants, and copolymer grades designed to meet the precise needs of pharmaceutical R&D, academic research, and industrial product development.

Refer full product list at resolvemass.ca : Products

Read below Learn with Us Articles:

PLGA Nanoparticles Synthesis: A Step-by-Step Guide for Beginners

PLGA 50:50 Poly(D L-lactide-co-glycolide) Supplier Guide: What to Look for in a Reliable Provider

The Science Behind GPC: A Deep Dive into Analyzing PLA, PLGA, and PCL for Research

Reviews

There are no reviews yet.