✅ Summary of Key Takeaways

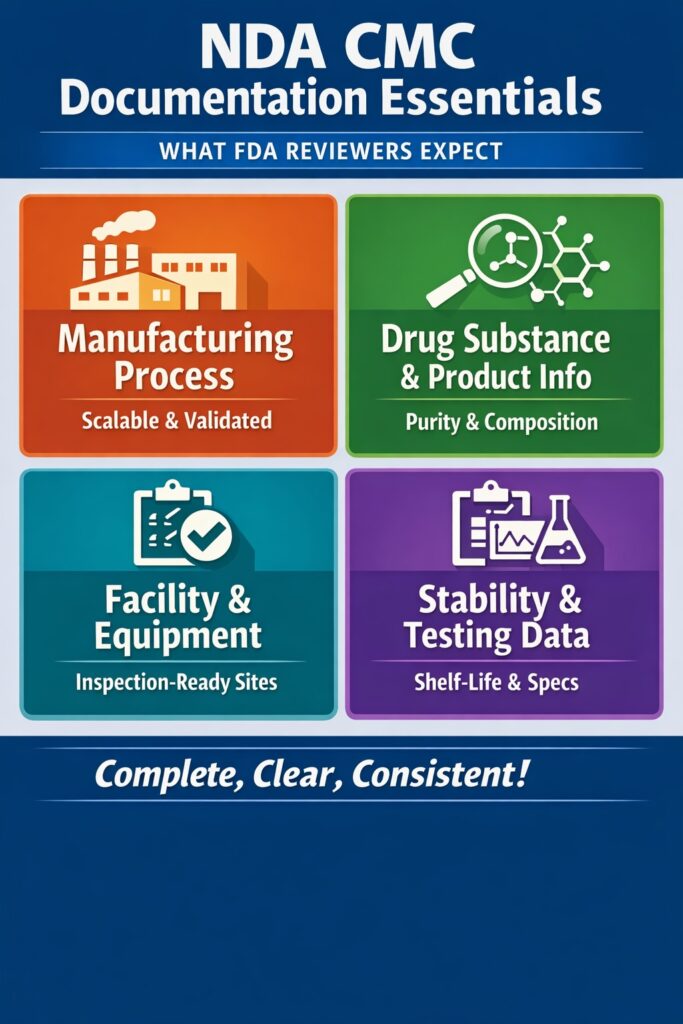

- FDA reviewers focus intensely on CMC documentation to ensure safety, consistency, and reproducibility of drug products.

- The CMC section of an NDA must prove product identity, strength, quality, purity, and stability.

- Errors or gaps in the CMC portion are among the top reasons for NDA delays or rejections.

- FDA expects detailed control strategies, validated processes, and risk-based justifications.

- A complete NDA CMC documentation checklist should be rooted in ICH guidelines, FDA guidances, and lifecycle management planning.

- This blog covers a section-by-section breakdown of the NDA CMC requirements with actionable insights from industry expectations.

- Includes a downloadable checklist to streamline CMC readiness.

- Focus keyword “NDA CMC Requirements” is used contextually throughout to align with search engine guidelines.

Introduction: Why the CMC Section Can Make or Break Your NDA

The NDA CMC requirements section is often the most detailed and time-consuming part of a drug application. It serves as proof that your product can be made consistently and at the right quality standard.

Your documentation should connect the development data, manufacturing steps, testing methods, and stability findings in a clear and logical way. If any part is unclear or missing, the FDA may delay or reject your application.

This article provides a practical checklist based on real-world FDA expectations. It helps ensure your submission is complete and aligned with what reviewers actually look for—not just the theoretical standards.

📄 NDA CMC Requirements Checklist: Section-by-Section Guide

1. 3.2.S Drug Substance (Active Ingredient)

This section must give a full picture of the drug substance, including how it’s made, what impurities might be present, and how quality is controlled. FDA reviewers look for traceability from raw materials to the final product.

Key items to include:

- General Information: Chemical name, structure, molecular formula, and consistency across all modules.

- Manufacturing Sites: List locations, roles, and quality agreements.

- Characterization: Include impurity profile, particle size, polymorphism, and solid-state form.

- Control of Drug Substance: Provide analytical procedures, validation data, and specs aligned with ICH Q6A.

- Reference Standards: In-house or pharmacopeial standards with certificates of analysis.

- Container Closure System: Show how the container protects the product.

- Stability: Include data supporting storage conditions and re-test periods.

✅ Expert Tip: Describe how impurities, especially mutagenic ones, are controlled per ICH M7.

Need expert support for your submission? Explore our specialized CMC services for IND and NDA filings to ensure regulatory compliance.

2. 3.2.P Drug Product (Finished Dosage Form)

This part shows the finished drug form meets quality standards consistently. It must explain how the formulation design and production steps connect to clinical outcomes.

Key items to include:

- Composition: Full quantitative formula with each excipient’s function.

- Pharmaceutical Development: Include rationale for design, excipient compatibility, and packaging choices.

- Manufacturing Process: Provide flowcharts, critical steps, in-process controls, and scale-up strategy.

- Control of Critical Quality Attributes (CQAs): Detail tests, criteria, and validation data.

- Container Closure System: Address extractables and leachables.

- Stability Data: Submit accelerated and long-term data with post-approval plans.

✅ Expert Tip: Use a control strategy summary table that aligns with ICH Q8–Q11 principles. For complex packaging, ensure you have comprehensive Extractables and Leachables testing to mitigate safety risks.

3. Facilities and Equipment

Your submission must list all facilities involved in manufacturing, testing, and packaging. Each facility should be inspection-ready and match what’s listed in FDA Form 356h.

Checklist items:

- Facility names and addresses with DUNS numbers

- Roles and responsibilities

- FDA inspection history and current readiness

- Environmental controls, especially for sterile areas

✅ Expert Tip: Include summaries of HVAC systems, water systems, and cleaning validations.

4. Process Validation and Control Strategy

Reviewers expect clear proof that your process consistently works at scale. This includes validation protocols and evidence that critical variables are controlled.

Include:

- Process Validation Master Plan (PVMP)

- Process Performance Qualification (PPQ) reports

- Validation of analytical methods

- In-process controls

- Management of CPPs and CMAs

Expert Tip: Understanding the transition from early-stage to late-stage is vital. Read our guide on IND vs NDA CMC requirements to stay ahead of the curve.

5. Analytical Method Validation

All testing methods must be validated to confirm they deliver reliable results. These methods support every quality decision throughout the product’s lifecycle.

Inclusions:

- Validation reports aligned with ICH Q2(R1)

- Data on robustness, specificity, and system suitability

- Protocols for method transfer or verification

✅ Expert Tip: Don’t forget to fully validate microbiological methods. If you are struggling with complex assays, consider our Analytical Method Development and Validation services.

6. Stability Data and Commitment

Stability studies must show that your product will remain effective and safe throughout its shelf life. The FDA expects data that support the proposed expiry and storage conditions.

Required data:

- Three batches (two pilot-scale, one commercial)

- 12 months long-term data

- 6 months accelerated data

- Justify matrixing or bracketing, if used

Also include:

- Ongoing stability programs

- Post-approval commitments

✅ Expert Tip: Add photostability data if your product is light-sensitive. Update your data before approval if new results become available.

Strategic Note: Comprehensive Forced Degradation studies are essential to justify your stability-indicating methods.

7. Specifications and Justifications

FDA wants to see that your specifications are realistic and based on data—not just set arbitrarily. They should reflect your manufacturing capability and clinical needs.

Best practices:

- Use data from clinical, stability, and commercial batches

- Refer to pharmacopeial standards

- Justify every limit with scientific evidence

✅ Expert Tip: Present all specification justifications in tables for clarity and ease of review.

📋 Sample CMC Specification Justification Table

| Attribute | Test Method | Specification Limit | Justification |

|---|---|---|---|

| Assay (API) | HPLC | 98.0% – 102.0% | Based on clinical batch performance and method validation |

| Dissolution (IR tabs) | USP Method | NLT 85% in 30 min | Supported by bioequivalence data showing rapid dissolution |

| Impurity A | HPLC | NMT 0.5% | Controlled via synthetic route and stability performance |

🧠 Common NDA CMC Review Deficiencies

Many applications face delays due to avoidable CMC issues. Knowing these can help you stay ahead.

Common problems:

- Weak method validation

- Not enough stability data

- Vague control strategies

- Poorly justified specs

- Incomplete batch records

- Missing excipient quality data

- Uncontrolled impurities: Specifically, failing to address Nitrosamine Analysis can lead to immediate halts.

✅ ResolveMass Insight: 70% of CRLs involve preventable CMC errors. Early planning can save time and cost.

🔍 Aligning NDA CMC Requirements with ICH and FDA Guidelines

Your CMC submission should closely follow FDA and international guidelines. This shows maturity and readiness for global approval.

Key references:

- ICH Q8–Q12 (covering development, quality, risk, and lifecycle management)

- FDA M4Q Guidance

- FDA Postapproval Changes Guidance

Following these improves your chances of approval and supports future changes with fewer delays.

Bridge the Gap: From the lab to the pharmacy shelf, our Chemistry, Manufacturing, and Controls (CMC) services provide the technical depth needed for success.

✅ Final NDA CMC Submission Checklist

| Category | Checklist Items |

|---|---|

| Drug Substance | Identity, control strategy, impurities |

| Drug Product | Manufacturing, composition, controls |

| Facilities | Site readiness, documentation |

| Validation | PPQ, analytical, cleaning |

| Stability | Long-term, accelerated, photostability |

| Specifications | Justified, clinically relevant |

| Risk Management | Control strategy, lifecycle approach |

📩 Conclusion: Mastering NDA CMC Requirements for FDA Approval

Meeting NDA CMC requirements is not just about compliance—it’s about showing scientific strength and a deep understanding of your product and process.

The FDA relies on this section to confirm your drug is safe, high-quality, and ready for commercial production. A well-prepared CMC section builds confidence and speeds up the review process.

Use this checklist to prepare a strong, clear submission. For complex products, expert guidance can make all the difference in achieving regulatory success.

📞 Need help with your CMC strategy?

Contact ResolveMass for expert review or schedule a compliance check.

Most Asked FAQs on NDA CMC Requirements

FDA typically requires data from three consecutive commercial-scale batches to demonstrate process consistency and reliability. These batches should be produced under approved protocols that reflect routine manufacturing conditions.

Yes, pilot-scale batches can be used if they are representative of the commercial process and scientifically justified. However, at least one commercial-scale batch is expected to support long-term stability claims.

Specification limits must be based on scientific evidence from clinical studies, manufacturing data, and stability results. These limits should reflect real process capability and meet regulatory expectations outlined in ICH Q6A.

FDA expects data proving that the container closure system maintains product stability, prevents contamination, and is compatible with the formulation. This includes assessments of extractables, leachables, and microbial barrier integrity.

The agency reviews how well the applicant has identified, monitored, and controlled critical quality attributes and sources of variability. A risk-based, lifecycle-focused strategy demonstrates strong quality management and process understanding.

Reference

- Popkin, M. E., Goese, M., Wilkinson, D., Finnie, S., Flanagan, T., Campa, C., Clinch, A., Teasdale, A., Lennard, A., Cook, G., & Mohan, G. (2022). Chemistry manufacturing and controls development, industry reflections on manufacture, and supply of pandemic therapies and vaccines. AAPS Journal, 24(6), Article 101. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9514697/

- Patel, D. H., Kumar, B. J., & Patel, A. A. (2017). Preparation and review of chemistry, manufacturing and control (CMC) sections of CTD dossier for marketing authorization. International Journal of Drug Regulatory Affairs, 5(2), 1–12. https://www.ijdra.com/index.php/journal/article/view/196