🔍 Summary – Key Takeaways

- Impurity profiling in CMC is central to ensuring drug safety, quality, and regulatory compliance.

- Regulatory scrutiny around nitrosamine risk assessment has intensified post-2018 recalls.

- A robust impurity strategy supports QbD, accelerates IND/NDA approval, and reduces lifecycle risks.

- FDA, EMA, ICH M7 & Q3 guidelines are primary drivers of impurity control frameworks.

- Integration of advanced analytical tools (LC-HRMS, GC-MS, NMR) is now indispensable.

- Establishing scientific thresholds and PDE values is critical to risk-based decision-making.

- Proactive impurity profiling supports global regulatory alignment and patient-centric outcomes.

- Companies with validated impurity profiling systems (like ResolveMass) gain an edge in regulatory acceptability and audit readiness.

🔬 Introduction: Why Impurity Profiling in CMC Must Address Nitrosamine Risks

Impurity profiling in CMC is a key factor in developing safe and effective medicines. The presence of low-level genotoxic impurities like nitrosamines can lead to delays, rejections, or even product recalls.

Due to their potential cancer risk, nitrosamines are now a top concern for global regulators. Linking impurity profiling in CMC with thorough nitrosamine risk assessments has become mandatory across all development stages.

Pharma companies must demonstrate accurate detection, proper control, scientific justification, and strategies to minimize nitrosamines from early development through post-marketing.

Ensure your development strategy is robust from day one. > Explore our Chemistry, Manufacturing, and Controls (CMC) Services

This article explores the growing importance of impurity profiling and nitrosamine risk assessment in CMC, their impact on regulatory submissions, and their role in long-term product safety.

🧬 How Impurity Profiling in CMC Supports Dossier Submissions

➤ Direct Relevance to Module 3 (ICH CTD Format)

Impurity profiling is essential for preparing Module 3 of the Common Technical Document (CTD), which evaluates the quality and safety of both the drug substance and product.

| CTD Section | Impurity-Related Content |

|---|---|

| 3.2.S.3.2 / 3.2.P.5.5 | Impurities in Drug Substance / Drug Product |

| 3.2.S.4.1 / 3.2.P.5.1 | Analytical Procedures for Impurity Testing |

| 3.2.S.4.3 / 3.2.P.5.3 | Validation of Analytical Procedures |

| 3.2.S.5 / 3.2.P.6 | Justification of Specifications |

An impurity profile must cover all possible impurities—organic, inorganic, elemental, solvents, and genotoxic. Limits and risk justifications should be well-supported with data.

Missing or weak impurity justifications can lead to regulatory questions, clinical holds, or refusals to file, slowing down development and approval timelines.

Navigate the complexities of regulatory filings with ease. > Learn more about NDA CMC Requirements

🧪 Nitrosamine Risk Assessment in Impurity Profiling in CMC

➤ Why Nitrosamines Are Now a Priority

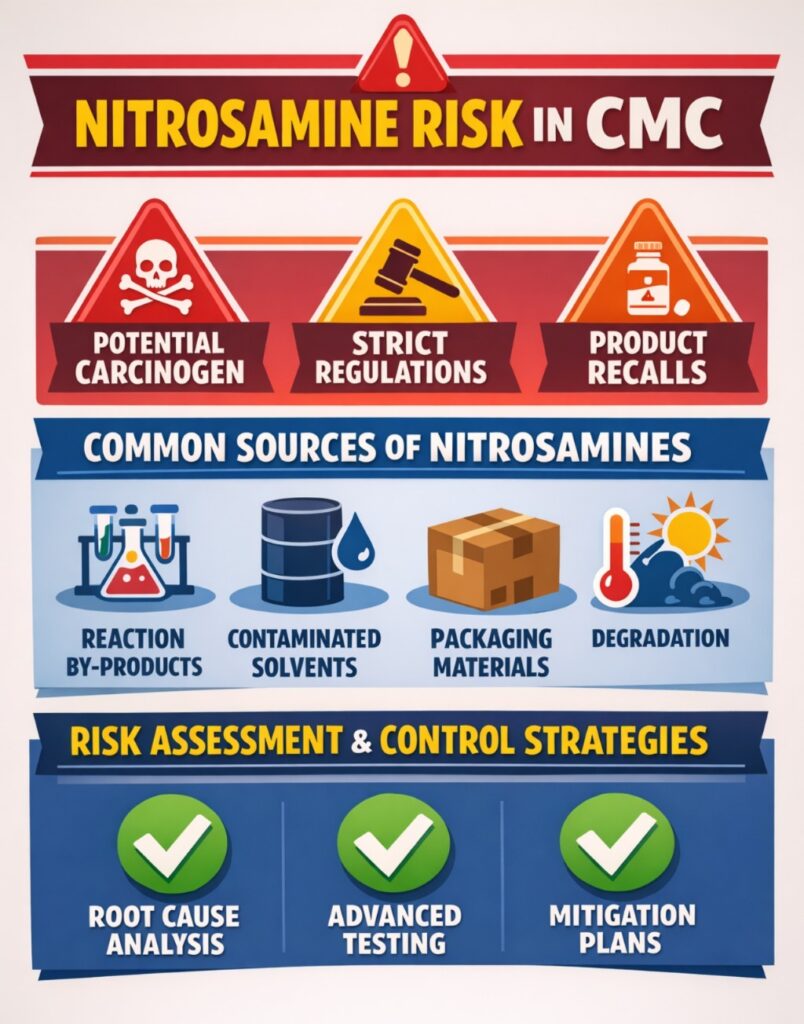

Since the 2018 recall of valsartan, nitrosamines have become a critical impurity class. Their potential as carcinogens has led to stricter regulations and tighter control requirements, often at parts-per-billion (ppb) levels.

This shift has increased the need for precision in both analytical testing and manufacturing controls. Companies must now understand how nitrosamines form and how to prevent their presence.

Regulatory Milestones:

- EMA Article 5(3) requires nitrosamine risk assessments for all active ingredients and related products.

- FDA Guidance (2021) calls for root cause analysis, confirmatory testing, and robust control measures.

➤ Common Sources of Nitrosamines

Nitrosamines can come from several sources, including:

- Reactions between nitrites and secondary amines during synthesis

- Contaminated solvents or reagents

- Packaging materials with nitrosating agents

- Degradation under heat, light, or moisture

Identifying these sources is key to controlling nitrosamine formation during product development.

Identify and mitigate risks before they impact your timeline. > Understand common CMC Deficiencies in IND and NDA

➤ Risk Assessment Approach

A nitrosamine risk assessment generally includes:

- Theoretical evaluation of potential nitrosamine formation based on structure and chemistry.

- Confirmatory testing using high-sensitivity tools like LC-HRMS.

- Mitigation planning such as process redesign, tightening impurity specs, and aligning with ICH M7 standards.

Stay compliant with the latest regulatory limits. > View our Nitrosamine AI Limit and CPCA Guide

🧰 Analytical Techniques for Impurity Profiling in CMC

A complete impurity profile requires multiple advanced techniques since no single method can detect all impurity types.

| Analytical Technique | Target Impurity Type | Relevance to CMC |

|---|---|---|

| LC-HRMS | Nitrosamines, genotoxic impurities | High sensitivity and structural ID |

| GC-MS | Volatile solvents, degradants | Required per ICH Q3C |

| ICP-MS | Elemental impurities | ICH Q3D compliance |

| NMR | Isomers, structural confirmation | Accurate impurity ID |

| UV/Vis, FTIR | Known degradants | Stability and identity checks |

All instruments must be validated per USP <1058> and ICH Q2(R2) to ensure reliability and reproducibility for regulatory filings.

Get precision testing for your regulatory submissions. > Discover Analytical Method Development for IND and NDA

📈 Strategic Benefits of Early Impurity Profiling in CMC

➤ Faster Approvals and Reduced Lifecycle Risk

Conducting impurity profiling early in development helps reduce surprises later. It identifies risks before scale-up and leads to faster filings like IND, IMPD, and NDA.

Early impurity data also improves Quality by Design (QbD) planning, reduces post-approval changes, and supports global regulatory alignment.

Build a strong foundation for your drug candidate. > Explore our IND CMC Strategy Services

➤ Scientific Justification for Specifications

Impurity levels may change across batches, so CMC teams need strong, data-backed justifications using methods like:

- Batch trend evaluations

- Stress testing and spiking studies

- In-silico models (QSAR) for genotoxic prediction

- Comparison with related substances (read-across)

These methods help ensure specifications are scientifically sound and regulatory-ready.

🧱 Lifecycle Control Strategies and Ongoing Impurity Monitoring

To maintain product quality, impurity profiling should be integrated into all control strategies, including raw material checks and in-process monitoring.

Any manufacturing changes must trigger impurity reassessment, even if small. Unchecked changes can introduce unexpected impurities.

Stability studies under ICH Q1A(R2) help identify degradants over time. Annual Product Reviews (APR) track trends and support CAPA actions.

Effective lifecycle impurity control ensures patient safety, regulatory compliance, and long-term product viability.

Ensure the purity of your active pharmaceutical ingredients. > Learn about Drug Substance Chemistry, Manufacturing, and Controls

🌍 Regulatory Landscape and Future of Impurity Profiling in CMC

➤ Global Harmonization of Impurity and Nitrosamine Control

Regulators like the FDA, EMA, PMDA, and TGA are now aligned on impurity and nitrosamine risk frameworks. This helps streamline submissions but raises expectations for quality systems.

The latest ICH M7(R2) draft expands guidance on PDEs, genotoxic impurity classifications, and acceptable control methods—especially for biologics and pediatric drugs.

➤ AI & Automation in Impurity Forecasting

Next-generation CMC planning uses AI and automation to predict and manage impurities. Tools like digital twins and cloud-based impurity databases are changing how risks are assessed.

ResolveMass Laboratories uses advanced AI-ML tools for impurity prediction, trend analysis, and readiness planning—giving clients faster results and improved compliance.

Streamline your path to market with expert CRO support. > Check out our CMC CRO Services

✅ Conclusion: Impurity Profiling in CMC is a Regulatory Imperative

In today’s pharma landscape, Impurity Profiling in CMC, including nitrosamine risk assessment, is not optional—it’s essential. Regulators expect detailed, proactive impurity control based on strong science.

Organizations that adopt validated profiling systems, leverage advanced tools, and follow ICH guidance can achieve smoother regulatory approvals and greater patient trust.

From early development to lifecycle maintenance, impurity profiling plays a vital role in ensuring drug safety, efficacy, and global market readiness.

📬 Contact ResolveMass Laboratories Inc.

Need expert support with Impurity Profiling in CMC or nitrosamine evaluations?

FAQs: Impurity Profiling in CMC and Nitrosamine Risk Assessment

Impurity profiling provides detailed information on the types and levels of impurities present in a drug substance or product. This data is essential for regulatory authorities to evaluate product safety, quality, and consistency during review and approval processes.

Nitrosamines are considered probable human carcinogens, even at very low concentrations. Their presence in pharmaceuticals has triggered global regulatory concern, making their detection, control, and justification a key part of impurity profiling efforts.

Impurity profiling is guided by ICH guidelines such as Q3A, Q3B, Q3C, Q3D, and M7, along with regional directives from the FDA and EMA. These guidelines define limits, testing methods, and risk assessment approaches for impurities, including nitrosamines.

Advanced analytical techniques like LC-HRMS and GC-MS are used to detect nitrosamines at parts-per-billion levels. These instruments provide high sensitivity and accuracy, which is essential for identifying even trace amounts of harmful impurities.

Permitted Daily Exposure (PDE) values are established to limit patient risk. For example, NDMA has a PDE of 96 ng/day, and NDEA has a PDE of 26.5 ng/day, as outlined in ICH M7 guidelines and associated regulatory documents.

Reference

- Popkin, M. E., Goese, M., Wilkinson, D., Finnie, S., Flanagan, T., Campa, C., Clinch, A., Teasdale, A., Lennard, A., Cook, G., & Mohan, G. (2022). Chemistry manufacturing and controls development, industry reflections on manufacture, and supply of pandemic therapies and vaccines. AAPS Journal, 24(6), Article 101. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9514697/

- Patel, D. H., Kumar, B. J., & Patel, A. A. (2017). Preparation and review of chemistry, manufacturing and control (CMC) sections of CTD dossier for marketing authorization. International Journal of Drug Regulatory Affairs, 5(2), 1–12. https://www.ijdra.com/index.php/journal/article/view/196

- U.S. Food and Drug Administration. (2024, November 19). Chemistry manufacturing and controls (CMC) guidances for industry (GFIs) and questions and answers (Q&As). U.S. Department of Health and Human Services. https://www.fda.gov/animal-veterinary/guidance-industry/chemistry-manufacturing-and-controls-cmc-guidances-industry-gfis-and-questions-and-answers-qas