Summary:

- FDA inspectors assess CMC sections to confirm product quality, consistency, and control—not theory or intent

- In an FDA CMC Inspection, reviewers expect alignment between what is written, what is executed, and what is documented

- IND CMC reviews emphasize developmental control and risk mitigation, while NDA CMC inspections focus on commercial readiness and lifecycle robustness

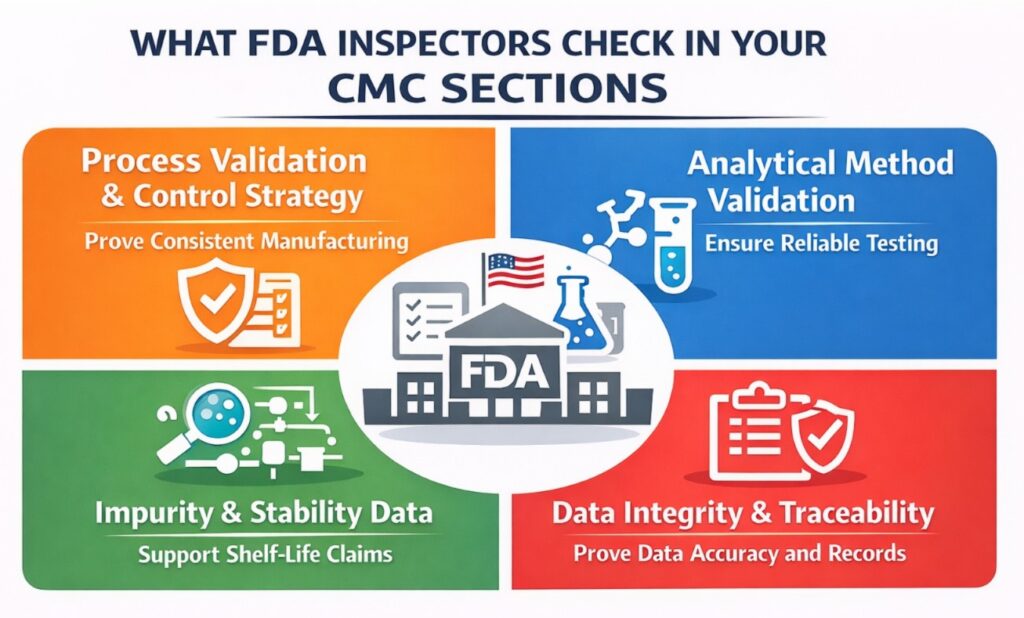

- Inspectors scrutinize process understanding, analytical method suitability, impurity control, stability strategy, and data integrity

- Most CMC deficiencies stem from inconsistencies, inadequate justification, or missing lifecycle rationale, not from lack of effort

- Well-structured, inspection-ready CMC sections reduce review cycles, information requests, and inspection risk

Introduction: Why FDA CMC Inspection Readiness Starts in the IND and NDA

In an FDA CMC Inspection, the Chemistry, Manufacturing, and Controls (CMC) sections of an IND or NDA are not viewed as static regulatory text. Instead, FDA treats them as a living reflection of product and process knowledge. Inspectors assume the information represents the sponsor’s most current and accurate understanding. Any outdated, aspirational, or unsupported statements are quickly identified during inspection.

From the FDA perspective, CMC sections must show full understanding of both drug substance and drug product. This includes how they are manufactured, tested, stored, and controlled over time. Inspectors want to see that outcomes are predictable and reproducible. Control strategies should clearly match the actual level of product risk.

This article explains what FDA inspectors look for in CMC sections during IND and NDA reviews. It focuses on practical inspection behavior rather than theory. The goal is to explain how experienced FDA reviewers interpret CMC data and narratives. Common inspection risks are highlighted to help sponsors reduce issues proactively.

Prepare your submission with proven regulatory expertise: Explore our IND & CMC Case Studies for Drug Discovery

How FDA Inspectors Read CMC Sections During an FDA CMC Inspection

FDA inspectors review CMC sections to confirm scientific understanding, manufacturing consistency, and maturity of control strategies. Compliance with formatting alone is not enough. Well-written language must be supported by real data. Inspectors are trained to look beyond structure and focus on substance.

During an FDA CMC Inspection, reviewers cross-check CMC narratives against internal records. These include batch manufacturing records, development reports, raw analytical data, stability protocols and results, and validation or tech transfer documents. Any discrepancy between these sources raises concern. The CMC section must accurately summarize these underlying records.

Inspectors are essentially asking one question:

Does this CMC section truthfully describe how the product is made, tested, and controlled today and at scale?

If the answer is unclear, scrutiny increases. Consistency signals control, while inconsistency signals risk.

Ensure your chemistry strategy is inspection-ready: Discover our Drug Discovery CRO Chemistry Services

What FDA Inspectors Look for in IND CMC Sections

FDA CMC Inspection Focus for INDs: Is Risk Understood and Controlled?

During IND reviews, FDA inspectors evaluate whether early-stage manufacturing risks are clearly identified, scientifically justified, and appropriately controlled for clinical use. Limited data is expected at this stage, but limitations must be intentional and explained. Patient safety remains the primary concern.

Key IND CMC Expectations During an FDA CMC Inspection

Sponsors must clearly distinguish development-stage decisions from future commercial intent. Inspectors expect clarity on what is provisional versus fixed. Data gaps must be justified using science, not cost or timeline pressures. Control strategies should match clinical risk rather than commercial standards.

Specific Areas Inspectors Scrutinize

1. Drug Substance Manufacturing

Inspectors review synthetic route clarity and rationale. Critical starting materials must be justified, and controls for reagents, solvents, and intermediates must be defined. Impurity fate and purge strategies should be logical and supported by data. Even at IND stage, structured impurity tracking is expected.

Known and potential impurities, including genotoxic or structurally related impurities, must be addressed. Risk-based approaches are acceptable when supported by sound reasoning. Unexplained impurity gaps often trigger follow-up questions.

2. Drug Product Formulation and Manufacturing

Formulation rationale must align with clinical use and dosing. Excipients should be suitable and compatible with the drug substance. Manufacturing flow diagrams must exactly match batch records. Any mismatch suggests weak documentation control.

3. Analytical Methods

Methods must be fit for their intended purpose, even if not fully validated. Inspectors expect method qualification, specificity, and suitability data. Platform or literature-based methods are acceptable with clear justification. Any known limitations must be openly stated.

4. Stability Strategy

Stability protocols must be scientifically justified and appropriate for clinical use. Acceptance criteria should be meaningful and linked to product performance. Stability commitments must be realistic and clearly described. Inspectors assess whether patient safety is adequately protected during trials.

Strengthen your early-stage impurity management: Learn about our Impurity Control Strategy in CMC

What FDA Inspectors Look for in NDA CMC Sections

FDA CMC Inspection Focus for NDAs: Is the Product Commercially Ready?

In NDA reviews, FDA inspectors expect full demonstration of process understanding, robust control strategies, and lifecycle readiness. Data must support long-term commercial manufacturing. NDA CMC sections are treated as binding commitments. Developmental language is no longer acceptable.

Core NDA CMC Expectations in an FDA CMC Inspection

Process validation data must demonstrate reproducibility at commercial scale. Analytical methods must be fully validated and lifecycle-managed. Specifications should be scientifically justified, not simply carried over from development. Stability data must support labeled shelf life and storage conditions.

Critical NDA CMC Areas Under FDA Inspection

1. Process Validation and Control Strategy

Inspectors look for clear linkage between Critical Process Parameters (CPPs), Critical Quality Attributes (CQAs), and controls. Stage 1, Stage 2, and Stage 3 validation activities must align. Ongoing process verification plans should be defined. Control strategies should prevent issues rather than rely only on detection.

Common findings include CPPs identified without experimental justification. Over-reliance on in-process testing instead of upstream control is frequently cited. Control strategies copied from development without scale justification raise concerns.

2. Analytical Method Validation and Lifecycle Management

FDA inspectors assess whether analytical methods are robust, transferable, and properly maintained over the product lifecycle. Validation protocols and reports are closely reviewed. System suitability, robustness, and method transfer studies must be complete and consistent.

Red flags include inconsistent acceptance criteria and missing impurity specificity studies. Unexplained method changes after validation often raise data integrity concerns.

3. Specifications and Justification

Specifications must directly link to clinical outcomes, stability data, and manufacturing capability. Limits require scientific and statistical justification. Drug substance and drug product specifications should align logically.

| Specification Element | FDA Inspection Expectation |

|---|---|

| Assay limits | Clinically relevant, stability-supported |

| Impurity limits | Toxicologically justified |

| Dissolution | Discriminatory and meaningful |

4. Stability Data and Shelf-Life Claims

FDA inspectors verify that shelf-life claims are fully supported by real-time and accelerated stability data. Protocol design, bracketing, and matrixing strategies are reviewed. OOS and OOT investigations must be thorough and well documented.

Common gaps include shelf-life extrapolation without statistical support. Inconsistent storage conditions across studies are frequently cited. Missing photostability justification also raises concerns.

Ensure your methods meet the highest validation standards: Custom Analytical Method Development for Drug Discovery

Data Integrity and Traceability: A Critical FDA CMC Inspection Factor

Even strong CMC science can fail an FDA CMC Inspection if data integrity is compromised. Inspectors routinely verify traceability from raw data to reported results. ALCOA+ principles must be followed in both laboratories and manufacturing environments. Audit trails for chromatographic systems are closely reviewed.

High-risk areas include manual integrations without justification, incomplete laboratory notebooks, and uncontrolled spreadsheets. These issues often lead to significant inspection observations.

Scale your department with compliant, high-quality chemistry: Explore our Virtual Chemistry Department CRO Services

Alignment Between CMC Narrative and Execution

One of the most common FDA CMC Inspection findings is misalignment between the written CMC sections and actual execution. Inspectors compare submissions against batch records, SOPs, and validation documents. Any inconsistency undermines credibility. FDA assumes that if something is written, it is executed exactly as described.

Partner with a team that prioritizes operational alignment: Outsourced Chemistry Services for Biotech

How to Reduce FDA CMC Inspection Risk in IND and NDA Submissions

Inspection-ready CMC sections are built through consistency, strong justification, and lifecycle thinking. Regulatory language alone does not reduce risk. Scientific clarity and operational alignment are far more important. FDA CMC Inspection readiness must be planned from early development.

Best Practices FDA Inspectors Respond Well To

Clear scientific rationale is preferred over excessive text. Honest discussion of limitations paired with mitigation strategies builds trust. A logical and consistent transition from IND to NDA is essential. Tables, diagrams, and cross-references should reflect actual execution.

Meet your clinical and regulatory deadlines effectively: Learn about CRO Chemistry Timelines for Drug Discovery

Conclusion: CMC Sections Drive FDA CMC Inspection Outcomes

An FDA CMC Inspection does not begin at the manufacturing site. It begins with the CMC sections of the IND or NDA. These sections shape FDA expectations and guide inspection focus. They directly influence regulatory confidence.

Sponsors who treat CMC as a scientific story supported by real data, clear justification, and lifecycle awareness experience smoother inspections. Strong alignment between development knowledge, manufacturing execution, and documentation turns CMC into a strategic advantage. This approach consistently supports faster approvals and fewer inspection findings.

Contact ResolveMass Today – Contact Us

Frequently Asked Questions (FAQs)

The biggest risk is providing limited data without a clear scientific explanation. FDA understands early development constraints, but inspectors expect sponsors to explain gaps and show how risks are managed. Unsupported assumptions raise concerns. Clear justification builds confidence.

IND CMC sections focus on understanding and controlling clinical risk. NDA CMC sections focus on consistent, commercial-scale manufacturing and long-term control. Expectations increase as the product moves closer to the market. NDA commitments are considered final and binding.

No, full validation is not required at the IND stage. However, methods must be suitable for their intended use and supported by qualification data. Inspectors expect sponsors to understand method limitations. Patient safety remains the priority.

Most observations result from weak process understanding or poorly justified specifications. Misalignment between development data and commercial claims is common. Inconsistent documentation also raises concerns. FDA expects strong scientific logic throughout.

Data integrity is extremely important and often a deciding factor. Even strong technical data can be rejected if records are incomplete or unreliable. FDA inspectors carefully review raw data and audit trails. Trust in data is essential.

Inspection readiness should start at the IND stage. Decisions made early often affect later submissions and inspections. Small inconsistencies can grow into major findings over time. Early planning reduces long-term risk.

Reference

- Patel, D. H., Kumar, B. J., & Patel, A. A. (2017). Preparation and review of chemistry, manufacturing and control (CMC) sections of CTD dossier for marketing authorization. International Journal of Drug Regulatory Affairs, 5(2), 1–12. https://www.ijdra.com/index.php/journal/article/view/196

- U.S. Food and Drug Administration. (2024, November 19). Chemistry manufacturing and controls (CMC) guidances for industry (GFIs) and questions and answers (Q&As). U.S. Department of Health and Human Services. https://www.fda.gov/animal-veterinary/guidance-industry/chemistry-manufacturing-and-controls-cmc-guidances-industry-gfis-and-questions-and-answers-qas