Introduction:

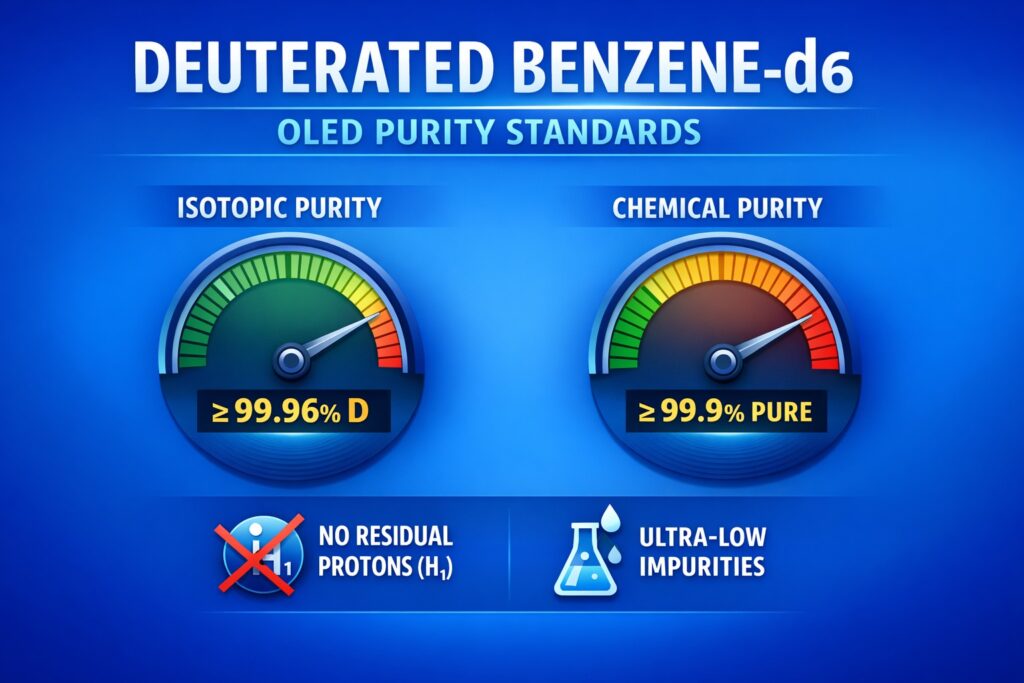

If you are planning to Buy Deuterated Benzene-d6 for OLED material research, it is important to choose a trusted and experienced isotope supplier. Procurement teams should work with well-known manufacturers such as Cambridge Isotope Laboratories (CIL), Sigma-Aldrich (MilliporeSigma), Eurisotop, or specialized providers like ResolveMass Laboratories Inc. The material must meet electronic-grade purity of ≥ 99.96 atom % D, especially for high-performance OLED development. This high enrichment level is not optional, as it directly affects device lifetime, brightness stability, and overall performance.

Explore our specialized catalog: Buy High-Purity Deuterated Compounds

Reputable suppliers provide detailed Certificates of Analysis (COAs), batch traceability, and full technical documentation. These documents help research teams maintain compliance and ensure repeatable results in material synthesis. When sourcing $C_6D_6$, it is always better to prioritize quality and purity over price, particularly for blue OLED systems where molecular stability is critical.

High-purity Deuterated Benzene-d6 supports the kinetic isotope effect (KIE), which improves the durability and efficiency of blue organic light-emitting diodes. Blue emitters operate at higher energy than red or green ones, which makes them more sensitive to bond degradation. Even small reductions in isotopic purity can reduce device lifetime. For this reason, careful supplier selection is essential when planning to Buy Deuterated Benzene-d6 for OLED applications.

Learn more about OLED-specific reagents: Deuterated Benzene-d6 for OLED Applications

Summary

- Choosing a trusted isotope supplier is essential when you buy Deuterated Benzene-d6 for OLED research, with ≥99.96 atom % D required for true electronic-grade performance.

- Electronic-grade material differs from NMR-grade solvent, and even small reductions in enrichment can significantly impact blue OLED lifetime and stability.

- Strict impurity control is critical, including ppb-level trace metal analysis (ICP-MS), low moisture content, and verified isotopic purity through NMR.

- High-purity C₆D₆ enhances the kinetic isotope effect (KIE), strengthening C–D bonds and improving device efficiency, brightness stability, and operational lifetime.

- Supplier evaluation should include COAs, batch traceability, packaging quality, global logistics compliance, and recovery/re-enrichment programs.

- Sustainable sourcing and circular recovery models reduce long-term costs while supporting reliable supply for advanced OLED material development.

Strategic Guidelines to Buy Deuterated Benzene-d6 for OLED Procurement

When companies Buy Deuterated Benzene-d6 for OLED production, one common challenge is distinguishing between NMR-grade solvent and true electronic-grade material. NMR-grade products are usually around 99.5% isotopic purity, which is sufficient for spectroscopy. However, advanced OLED host synthesis, especially for deep-blue PhOLEDs, requires 99.96% deuterium enrichment or higher to fully benefit from the kinetic isotope effect.

A difference of just a few tenths of a percent may seem small, but in OLED devices it can significantly affect long-term stability. Residual $C-H$ bonds increase the risk of bond breaking under electrical stress. Therefore, procurement teams should verify enrichment data using reliable analytical methods instead of depending only on marketing specifications. Direct technical discussions with suppliers can also clarify whether the material was produced specifically for electronic applications.

Access comprehensive analytical services: Analytical Characterization of Deuterated Compounds

ResolveMass Laboratories Inc. recommends choosing suppliers that provide not only isotopic purity data but also detailed trace metal analysis. In today’s display market, where technologies such as LG Display’s “EX Technology” use deuterium to boost brightness by up to 30%, material consistency is a competitive advantage. Reliable quality systems, strong packaging standards, and recovery programs should all be part of the evaluation process.

Essential Purity Standards When You Buy Deuterated Benzene-d6 for OLED Research

When deciding where to Buy Deuterated Benzene-d6 for OLED research, isotopic purity must remain the top technical priority. Residual protium ($^1H$) acts as a weak point under electrical excitation. In blue phosphorescent OLEDs, even a small percentage of non-deuterated molecules can create instability in the emitting layer.

The scientific explanation comes from the difference in zero-point energy between $C-H$ and $C-D$ bonds. Because deuterium is heavier than hydrogen, $C-D$ bonds vibrate at lower frequency. This lowers zero-point energy and increases bond strength. As a result, more energy is required to break the bond during device operation.

Find specialized synthesis partners: Custom Deuterated Compounds Synthesis

In practical terms, this means improved resistance to degradation in the recombination zone of the OLED. Higher isotopic enrichment directly supports longer device lifetime and improved operational reliability. For research teams focused on next-generation displays, maintaining ≥99.96% D is strongly recommended.

Impact of Trace Metal Contaminants When You Buy Deuterated Benzene-d6 for OLED Fabrication

Trace metal contamination is another critical factor when teams Buy Deuterated Benzene-d6 for OLED fabrication. Metals such as Palladium ($Pd$), Platinum ($Pt$), and Gold ($Au$) can act as charge traps or non-radiative recombination centers. Even very low concentrations may reduce efficiency and shorten device lifetime.

Electronic-grade materials should be tested at parts-per-billion (ppb) or even parts-per-trillion (ppt) levels. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is the preferred method because of its high sensitivity. Standard NMR-grade solvents are usually not tested at these strict levels, which is why additional validation is important.

View our full chemical availability: Availability of All Deuterated Chemicals

| Contaminant Type | Target Limit (Electronic Grade) | Analytical Method | Impact on Device |

|---|---|---|---|

| Trace Metals ($Pd, Pt, Au$) | $<10\text{ ppb}$ | ICP-MS | Exciton quenching |

| Residual Water ($H_2O$) | $<0.005%$ | Karl Fischer | Cathode interface degradation |

| Halogens ($Cl, Br$) | Not Detectable | GC-ECD | Corrosion of ITO |

| Organic Impurities | $<0.1%$ | GC-FID | Film instability |

Research has shown that replacing $C-H$ bonds with $C-D$ bonds using high-purity $C_6D_6$ can increase OLED lifetime several times without lowering efficiency. However, this benefit can be reduced if contaminants are present. Strong quality control protects both device performance and research investment.

Technical Applications of Deuterated Benzene-d6 in OLED Material Innovation

Deuterated Benzene-d6 is not only a solvent but also a key building block for advanced OLED materials. It is widely used to synthesize perdeuterated aromatic hosts and fluorophores. Anthracene-based hosts prepared from $C_6D_6$ have shown strong improvements in operational lifetime as deuteration increases.

In some blue OLED systems, lifetime has improved by several times compared to non-deuterated versions. Deuterated materials also support hole-transport materials and exciplex systems. By strengthening the molecular backbone, deuteration improves film stability and reduces phase separation.

Discover reagents for the electronics industry: Deuterated Reagents for Electronics

As OLED designs continue to evolve, isotopic engineering has become a standard strategy in high-performance material development. This makes the decision to Buy Deuterated Benzene-d6 for OLED research even more important for long-term innovation.

The Role of Deuteration in Suppressing Degradation

Blue excitons carry high energy and can damage traditional organic molecules. In protonated systems, $C-H$ bonds can break and form unwanted by-products that reduce light output. Deuteration reduces this risk because $C-D$ bonds are stronger and more resistant to photodegradation.

Advanced analysis methods such as LDI-TOF mass spectrometry show fewer degradation products in deuterated systems. This helps maintain purity in the emitting layer over longer operation times. Improved molecular packing and lower reorganization energy have also been observed in deuterated hosts.

Consult with a leading North American supplier: Deuterated Labelled Chemical Synthesis in Canada

These benefits can lead to lower operating voltage and higher external quantum efficiency. Overall, isotopic substitution offers measurable electrical and optical advantages in OLED systems.

Synthesis and H/D Exchange Efficiency

For researchers performing late-stage deuteration, choosing the right isotopic source is essential. Hydrogen-Deuterium Exchange (HDE) methods using $C_6D_6$ are common but require proper catalysts and reaction control.

Catalytic Systems: Iridium and ruthenium catalysts enable high deuterium incorporation at moderate temperatures. Reaction conditions must be optimized to avoid incomplete exchange.

Flow Chemistry: Continuous-flow systems improve control and reduce isotopic loss. They also increase reproducibility and scalability.

Grignard Reagents: While $D_2O$ can introduce deuterium, it often provides limited incorporation. For fully deuterated aromatic systems, $C_6D_6$ remains more suitable.

Logistics, Hazardous Materials, and Safety Compliance

Managing Hazardous Material Compliance to Buy Deuterated Benzene-d6 for OLED Shipping

When planning to Buy Deuterated Benzene-d6 for OLED use, safety regulations must be followed carefully. Benzene-d6 is flammable and classified as UN1114, Class 3, Packing Group II. International shipping must comply with IBC, IATA, and DOT regulations.

Shipments require proper labeling, approved containers, and trained handling personnel. Small research quantities may qualify for limited quantity exceptions, but packaging standards still apply. Institutions should coordinate with Environmental Health and Safety (EHS) teams before ordering.

Laboratory Handling and Glovebox Protocols

To protect isotopic purity, electronic-grade $C_6D_6$ should be handled under inert atmosphere, usually nitrogen or argon. Exposure to air may introduce moisture and reduce deuterium enrichment over time.

| Protocol Stage | Requirement | Reason |

|---|---|---|

| Glovebox Entry | 3 Vacuum/Vent Cycles (15 mins) | Remove oxygen and moisture |

| Gloves Selection | Viton, Neoprene, or PVA | Standard nitrile is permeable to benzene |

| Spill Response | Immediate evacuation/EHS notification | Benzene vapor toxicity |

| Storage | $6^\circ\text{C} – 15^\circ\text{C}$ away from light | Prevent thermal and photolytic degradation |

Regular moisture monitoring inside gloveboxes helps maintain stable material quality and ensures safe laboratory practice.

Find high-quality standards for your lab: Deuterated Internal Standards and Reference Materials

Sustainable Sourcing: The Circular Economy of Isotope Research

Economic Advantages When You Buy Deuterated Benzene-d6 for OLED Through Recovery Programs

Organizations that Buy Deuterated Benzene-d6 for OLED manufacturing can reduce costs by joining recovery and re-enrichment programs. Some suppliers reclaim depleted solvent and restore its isotopic value. This approach lowers waste and supports long-term supply stability.

Recovery programs offer three main benefits. First, they reduce overall material expenses. Second, they lower hazardous waste disposal requirements. Third, they help conserve deuterium resources, which are limited and valuable.

As OLED production expands globally, especially in Asia, strong and sustainable supply chains are becoming increasingly important. Circular sourcing models align economic savings with environmental responsibility.

Analytical Methods for Quality Assurance

When selecting a supplier to Buy Deuterated Benzene-d6 for OLED research, analytical capability should be carefully reviewed. A reliable COA must be supported by validated testing methods.

Nuclear Magnetic Resonance (NMR) for Isotopic Integrity

NMR confirms deuterium incorporation and solvent identity. A high-purity sample shows a minimal residual $^1H$ peak and a strong $^2H$ lock signal. Characteristic carbon-deuterium coupling patterns also confirm enrichment.

Routine batch verification before large-scale synthesis ensures consistent material performance.

ICP-MS for Electronic-Grade Validation

ICP-MS provides ppt-level detection of trace metals. This level of sensitivity is required for electronic-grade materials. Detecting residual palladium or other catalyst metals prevents performance loss in final OLED devices.

Conclusion

Choosing where to Buy Deuterated Benzene-d6 for OLED material research is a critical technical decision. High-purity $C_6D_6$ enables stronger molecular bonds, improved efficiency, and longer device lifetime through the kinetic isotope effect. For advanced display technologies, electronic-grade standards are essential.

By focusing on ultra-high enrichment, strict trace metal control, and sustainable sourcing programs, research and manufacturing teams can confidently scale from laboratory work to commercial production. ResolveMass Laboratories Inc. supports customers with expert guidance, analytical validation, and reliable supply of electronic-grade isotopes.

Ready to source your materials? Supplier of High-Quality Deuterated Reagents

For procurement inquiries or technical assistance, please contact the ResolveMass team:

Contact us

Frequently Asked Questions (FAQs)

For blue PhOLED host materials, 99.96% deuterium enrichment is widely accepted as the industry standard. Lower purity levels can leave small amounts of $C-H$ bonds in the structure. These weak points may break down faster under electrical stress, reducing the overall lifetime of the OLED device. For high-performance applications, higher enrichment gives more reliable and stable results.

The kinetic isotope effect happens because deuterium is heavier than hydrogen. This extra mass makes the $C-D$ bond stronger and more resistant to vibration and breaking. As a result, the emitting layer becomes more stable under high-energy excitons. Over time, this slows chemical degradation and helps extend the operational life of the OLED.

NMR-grade $C_6D_6$ is mainly designed for spectroscopy and focuses on reducing proton signals for clean spectra. Electronic-grade material goes further by controlling trace metals, moisture, and organic impurities at very low levels. These extra purity standards are important because contaminants can reduce brightness, efficiency, and device stability in OLED stacks.

Yes, bulk quantities are available from major isotope suppliers. Many manufacturers also offer recovery and re-enrichment programs for used material. This approach helps lower long-term costs and ensures a steady supply for continuous production. Bulk sourcing is common in commercial OLED fabrication.

Deuterated materials can slightly shift the emission toward deeper blue in some OLED systems. This small shift can help manufacturers meet strict display standards such as DCI-P3. Improved molecular stability also supports consistent light output over time. Overall, deuteration can enhance both performance and color accuracy.

Benzene has a simple and symmetrical ring structure, which makes full hydrogen replacement easier to achieve. It is also a common starting point for many OLED host and transport materials. Because of this versatility, deuterated benzene becomes a flexible building block in material design. Its structure supports efficient and uniform deuteration.

Reference

- Yuan, W., Huang, T., Zhou, J., Tang, M.-C., Zhang, D., & Duan, L. (2024). High-efficiency and long-lifetime deep-blue phosphorescent OLEDs using deuterated exciplex-forming host [Preprint]. ChemRxiv. https://doi.org/10.26434/chemrxiv-2024-8bn7g

- Yao, J., Dong, S.-C., Tam, B. S. T., & Tang, C. W. (2023). Lifetime enhancement and degradation study of blue OLEDs using deuterated materials. ACS Applied Materials & Interfaces, 15(5), 7255–7262. https://doi.org/10.1021/acsami.2c22882

- Kopf, S., Bourriquen, F., Li, W., Neumann, H., Junge, K., & Beller, M. (2022). Recent developments for the deuterium and tritium labeling of organic molecules. Chemical Reviews, 122(6), 6634–6718. https://doi.org/10.1021/acs.chemrev.1c00795

- Tsuji, H., Mitsui, C., & Nakamura, E. (2014). The hydrogen/deuterium isotope effect of the host material on the lifetime of organic light-emitting diodes. Chemical Communications, 50(94), 14870–14872. https://doi.org/10.1039/c4cc05108d

- Tatoueix, K., Lepron, M., Barboux, C., Scherrmann, M.-C., Pieters, G., & Feuillastre, S. (2025). Unlocking the potential of hydrogen deuterium exchange via an iterative continuous-flow deuteration process. Nature Communications, 16, 1314. https://doi.org/10.1038/s41467-025-56600-8