Article Overview

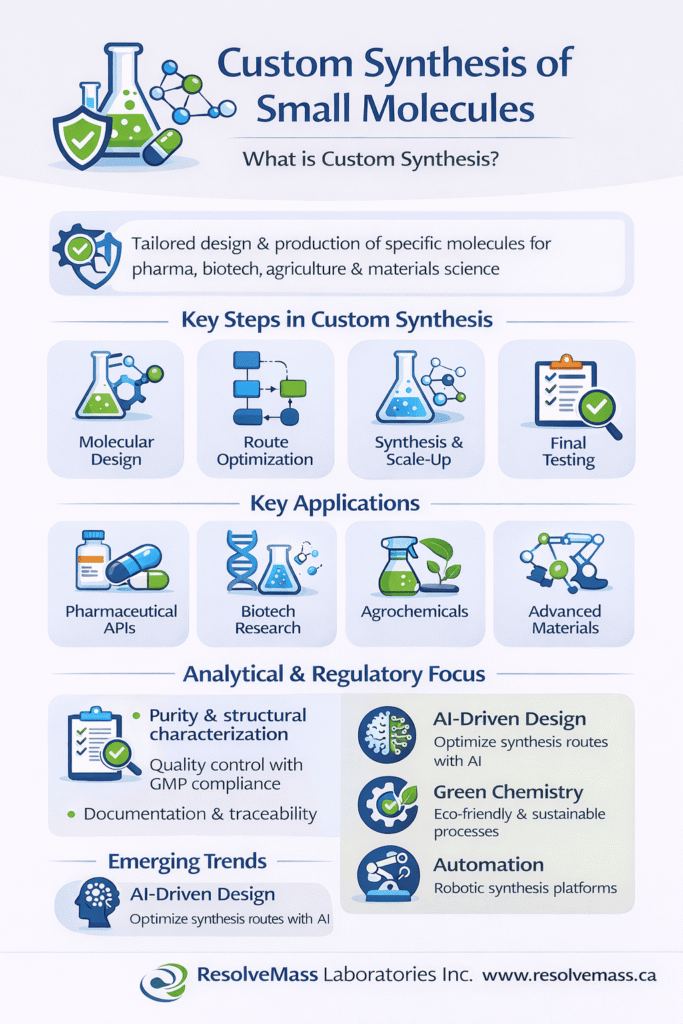

- Explains the fundamentals of custom synthesis of small molecules and its importance in pharmaceutical, biotech, agricultural, and materials research

- Outlines the end-to-end custom synthesis process, from molecular design and route optimization to scale-up and final testing

- Highlights the strategic role of custom synthesis in early-stage drug discovery, including SAR studies and lead optimization

- Covers key applications across industries, including APIs, biotechnology research, agrochemicals, and advanced materials

- Discusses analytical characterization, quality control, and regulatory considerations essential for reproducible and compliant synthesis

- Explores emerging trends such as AI-driven molecular design, automation, green chemistry, and sustainable synthesis practices

Custom synthesis of small molecules plays a pivotal role in the fields of pharmaceuticals, biotechnology, and chemical research. It involves the tailored design and production of specific organic compounds based on the needs of researchers and industries. This process enables the development of novel drugs, agrochemicals, and specialty materials with precise structural and functional attributes.

In this guide, we will explore the essentials of custom synthesis, its methodologies, applications, and emerging trends. Whether you are a researcher, a pharmaceutical professional, or simply curious about the process, this comprehensive guide will provide valuable insights.

Wonder where custom synthesis is applied? Custom Synthesis in Canada for Pharmaceutical Research and Development – here’s how it supports real R&D.

🏭 Custom Synthesis in Canada: Fueling R&D Progress

👉 Learn how Canadian expertise in custom synthesis drives innovation »

Understanding Custom Synthesis

Definition and Importance

Custom synthesis refers to the process of designing and manufacturing small molecules according to specific requirements. Unlike bulk chemical manufacturing, which focuses on large-scale production of standardized compounds, custom synthesis caters to unique molecular needs. This specialized service is critical for industries requiring novel chemical entities, including pharmaceuticals, material sciences, and biotechnology.

The importance of custom synthesis lies in its ability to:

- Enable the discovery of new drugs and therapies.

- Support the development of advanced materials.

- Facilitate academic and industrial research.

- Improve efficiency in chemical manufacturing.

Strategic Benefits of Custom Synthesis for Pharmaceutical Innovation

Custom synthesis offers pharmaceutical companies a strategic advantage by enabling precise control over molecular architecture during early research and development. Instead of adapting research to commercially available compounds, scientists can design molecules that directly address biological targets, solubility challenges, or stability limitations. This flexibility significantly accelerates lead optimization and reduces the trial-and-error phase commonly encountered in drug discovery.

In addition, custom synthesis supports intellectual property protection by allowing organizations to develop proprietary molecular entities that differentiate their pipelines from competitors. Tailored synthesis pathways also allow early identification of potential scale-up challenges, helping teams refine chemistry before entering late-stage development. As a result, pharmaceutical innovators can move from concept to clinic with greater confidence and efficiency.

🧬 Custom Synthesis in Polymer Science

Learn how custom synthesis, even in the realm of polymer science, plays a pivotal role in driving advancements across pharmaceuticals, electronics, and sustainable technologies. 👉 Explore the impact of polymer synthesis on modern science »

Learn now custom synthesis, even in polymer science, plays a key role in modern technology – The Importance of Polymer Synthesis in Modern Science and Technology

Key Stages of Custom Synthesis

The custom synthesis process typically involves multiple stages, each crucial for ensuring the accuracy, purity, and efficacy of the synthesized compound.

- Conceptualization and Design: This phase involves understanding the client’s requirements and designing the molecular structure accordingly.

- Route Selection and Optimization: Chemists determine the most efficient synthetic pathway to produce the molecule while minimizing waste and cost.

- Synthesis and Scale-Up: The molecule is synthesized in a laboratory setting and, if needed, scaled up for larger production.

- Characterization and Purification: The synthesized molecule undergoes rigorous testing to ensure it meets purity and structural requirements.

- Final Testing and Documentation: The compound is subjected to analytical testing, regulatory compliance checks, and documentation before delivery to the client.

Want a clear idea of how the entire synthesis process works? Step-by-Step Guide to Custom Polymer Synthesis Process – This guide walks you through it step-by-step.

Role of Custom Synthesis in Early-Stage Drug Discovery

In early-stage drug discovery, custom synthesis plays a foundational role by enabling rapid access to novel chemical entities for biological screening. Medicinal chemists rely on custom-synthesized compounds to explore structure–activity relationships (SAR), helping them understand how small structural changes influence biological response. This iterative process would be impossible without the flexibility offered by bespoke synthesis solutions.

Furthermore, early-stage programs often require small quantities of highly specialized compounds rather than bulk materials. Custom synthesis laboratories are equipped to deliver milligram-to-gram quantities with high purity, ensuring consistency across screening campaigns. This precision reduces variability in experimental outcomes and strengthens decision-making during candidate selection.

Applications of Custom Synthesis

Custom synthesis of small molecules is widely used across various industries, including pharmaceuticals, agriculture, and materials science.

Pharmaceutical Industry

In the pharmaceutical sector, custom synthesis is essential for developing active pharmaceutical ingredients (APIs) and intermediates. Drug discovery relies on the synthesis of novel molecules that can act as potential therapeutic agents. Companies engaged in drug development often require specific compounds tailored to their research and clinical trials.

Biotechnology and Life Sciences

Biotechnological research frequently demands unique molecular structures for biochemical studies, enzyme inhibitors, and diagnostic agents. Custom synthesis services enable researchers to explore complex biological mechanisms using highly specific compounds.

Agricultural Chemistry

Pesticides, herbicides, and fungicides require precise molecular configurations to ensure efficacy and environmental safety. Custom synthesis allows agrochemical companies to design and produce molecules with optimal biological activity.

Materials Science

Advanced materials such as conductive polymers, nanomaterials, and functionalized coatings often involve small molecules synthesized with high precision. These compounds enhance the performance of electronics, sensors, and industrial applications.

Wondering how custom synthesis fits into modern science? Emerging Trends in Custom Polymer Synthesis for 2025 and Beyond – this explains it clearly.

Quality Control and Analytical Support in Custom Synthesis Projects

Robust quality control is a critical component of any custom synthesis project, particularly when compounds are intended for regulated research or pharmaceutical use. Analytical characterization confirms molecular identity, purity, and structural integrity using techniques such as NMR, LC-MS, IR spectroscopy, and elemental analysis. These data ensure that synthesized compounds meet predefined specifications before being used in downstream applications.

Equally important is comprehensive documentation, including analytical reports and batch records, which support reproducibility and regulatory confidence. High-quality analytical support not only validates the success of the synthesis but also provides valuable insight into impurity profiles and reaction performance. This level of transparency strengthens collaboration between synthesis partners and research teams.

Methodologies in Custom Synthesis

The synthesis of small molecules involves various methodologies, depending on the complexity of the compound and the desired purity.

Organic Synthesis Techniques

- Traditional Organic Synthesis: Involves stepwise reactions to build complex molecular structures.

- Solid-Phase Synthesis: Commonly used in peptide and oligonucleotide synthesis, allowing for efficient purification.

- Microwave-Assisted Synthesis: Speeds up reaction times and enhances yields compared to conventional methods.

Custom Organic Synthesis in Montreal – a good read if you’re curious about how custom synthesis methods are actually used in labs.

🧪 Curious About Real Lab Applications?

A good read if you’re curious about how custom synthesis methods are actually applied in labs—from route design to scale-up and impurity isolation.

👉 Discover how lab-based synthesis drives innovation »Green Chemistry Approaches

With growing concerns over sustainability, green chemistry techniques aim to reduce waste and improve efficiency.

- Biocatalysis: Uses enzymes to catalyze reactions under mild conditions.

- Flow Chemistry: Enables continuous production with better control over reaction parameters.

- Solvent-Free Reactions: Minimize the use of hazardous solvents, making processes more environmentally friendly.

PLGA is a great example of green chemistry in action, PLGA 50:50 Poly(D L-lactide-co-glycolide) Supplier Guide – this explains why.

Challenges in Custom Synthesis

Despite its advantages, custom synthesis presents certain challenges that must be addressed.

Technology Transfer and Scale-Up Considerations

Technology transfer is a crucial step when custom-synthesized molecules transition from laboratory research to larger-scale manufacturing. During this phase, synthetic routes must be evaluated for robustness, safety, and reproducibility. Parameters such as reaction yield, solvent selection, and raw material availability are carefully assessed to ensure scalability without compromising product quality.

Scale-up also introduces operational challenges, including heat transfer, reaction kinetics, and impurity control. Experienced custom synthesis partners anticipate these issues early and adapt processes accordingly. By addressing scalability during development, organizations reduce the risk of costly delays when advancing compounds toward commercial production.

Complexity of Molecular Design

Designing novel molecules requires extensive knowledge of organic chemistry, reaction mechanisms, and computational modeling.

Scalability and Cost Efficiency

Scaling up synthesis while maintaining cost efficiency is a major challenge. Process optimization and alternative synthetic routes help mitigate these issues.

Regulatory Compliance

Pharmaceutical and chemical industries must adhere to strict regulatory guidelines. Ensuring compliance with agencies like the FDA and EMA adds complexity to custom synthesis projects.

A simple breakdown of the biggest challenges researchers faces in custom synthesis – Top Challenges and Opportunities in Custom Polymer Synthesis

Future Trends in Custom Synthesis

The field of custom synthesis is evolving with advancements in technology and methodologies.

Choosing the Right Custom Synthesis Partner

Selecting the right custom synthesis partner is essential for the success of research and development programs. Beyond technical expertise, organizations should evaluate a partner’s ability to communicate clearly, meet timelines, and adapt to evolving project requirements. A reliable partner functions as an extension of the client’s scientific team rather than a transactional service provider.

Additionally, factors such as regulatory awareness, data integrity practices, and confidentiality protocols play a significant role in long-term collaboration. Laboratories with strong quality systems and multidisciplinary expertise can support projects from early discovery through advanced development. Choosing a capable synthesis partner ultimately enhances efficiency, reduces risk, and supports sustainable innovation.

AI-Driven Drug Discovery

Artificial intelligence is revolutionizing molecular design by predicting the most promising drug candidates and optimizing synthesis routes.

🤖 Curious How AI Is Designing Molecules?

AI is redefining how we create and optimize polymers — faster, smarter, and more efficiently than ever before. If you’re interested in the future of molecular design, this is a must-read.

👉 Explore how AI is revolutionizing polymer synthesis »Automation and Robotics

Automated synthesis platforms and robotic laboratories are enhancing efficiency and reproducibility in chemical manufacturing.

Sustainable Chemistry

Green chemistry practices are becoming more prevalent, focusing on reducing environmental impact and improving process efficiency.

Curious how AI is changing the way molecules are designed? This is a must read – How AI Is Revolutionizing Custom Polymer Synthesis

Conclusion: Why Custom Synthesis Is a Cornerstone of Modern Science

Custom synthesis of small molecules is a cornerstone of modern scientific innovation, enabling researchers and industries to transform ideas into tangible chemical solutions. From early-stage discovery to advanced material development, tailored synthesis provides the flexibility, precision, and control required to address complex scientific challenges.

As technologies evolve and sustainability becomes a greater priority, custom synthesis will continue to adapt through automation, digital tools, and greener methodologies. By combining chemical expertise with strategic collaboration, custom synthesis not only accelerates innovation but also strengthens the foundation of pharmaceutical, biotechnological, and materials research worldwide.

REFERENCES

- Chemxpert. (2025, May 22). Everything you need to know about custom synthesis. Chemxpert. Retrieved January 6, 2026, from https://chemxpert.com/blog/everything-you-need-to-know-about-custom-synthesis

- Shinde, V. (2024, January 27). Custom synthesis in pharmaceuticals: Advantages and challenges. Veeprho. Retrieved January 6, 2026, from https://veeprho.com/custom-synthesis-in-pharmaceuticals-advantages-and-challenges/

LET’S CONNECT

At ResolveMass Laboratories Inc., we are committed to providing high-quality custom synthesis of small molecules tailored to your research and development needs. Whether you’re in the pharmaceutical, biotech, or chemical industry, our expert team is ready to assist you with cutting-edge solutions.

Case Study: Root Cause Investigation of Unexpected NDMA Spike in Finished Product

Introduction In this NDMA Root Cause Investigation Case Study, we examine a real-world scenario involving…

Selecting the Right Nitrosamine Testing CRO: A Technical Due Diligence Checklist

Introduction Nitrosamine Testing CRO Selection requires detailed scientific evaluation and regulatory awareness. Global authorities continue…

Case Study: Sameness Evaluation of Semaglutide Generic project submission to Health Canada

Introduction: Semaglutide Sameness Evaluation for Health Canada is a scientifically rigorous analytical process required to…

Analytical Testing Services for Peptide-Oligonucleotide Conjugates

Introduction: Why Specialized Peptide Oligonucleotide Conjugate Analysis Is Essential Peptide Oligonucleotide Conjugate Analysis is critical…

NDA vs ANDA Nitrosamine Data Requirements: What Sponsors Must Submit

Introduction: The global pharmaceutical industry is facing strict regulatory control for mutagenic impurities, especially nitrosamines….

How to Prepare a Complete Nitrosamine Risk Assessment Report for ANDA Submission

Introduction A comprehensive Nitrosamine Risk Assessment for ANDA Submission requires a structured and scientific evaluation…