Introduction

Nitrosamine Testing in Azithromycin has become an important safety and quality step after global alerts from Health Canada, the US FDA, and the European Medicines Agency (EMA) about the risk of nitrosamine impurities in medicines. Azithromycin, a macrolide antibiotic made from erythromycin, can sometimes develop N-nitroso impurities during manufacturing or storage. These impurities may form in both the active pharmaceutical ingredient (API) and finished products. Careful testing of raw materials, synthesis steps, solvents, and excipients is needed to detect and prevent nitrosamines, especially Nitrosamine Drug Substance Related Impurities (NDSRIs). Since nitrosamines are considered possible human cancer-causing agents, strict testing is a top priority for pharmaceutical safety worldwide.

Learn about nitrosamine impurity limits for Health Canada submissions

Understanding the Synthesis of Azithromycin

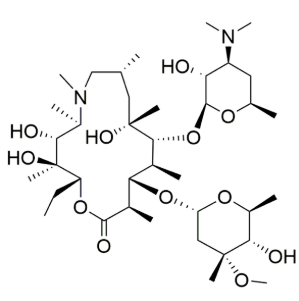

Azithromycin is a 15-membered azalide antibiotic created by modifying erythromycin A. Its structure includes a nitrogen atom added into the lactone ring, which improves stability in acidic environments. The industrial process often starts with fermentation to make erythromycin, followed by chemical steps such as reductive amination, oxime formation, and ring expansion using amine-rich intermediates. These nitrogen-heavy materials, combined with certain solvents and catalysts, can create opportunities for nitrosamine formation if nitrosating agents are present. By improving process control and testing during production, manufacturers can greatly reduce the chances of contamination.

Nitrosamine Risk Assessment in Azithromycin API Synthesis

Producing Azithromycin at an industrial scale involves several steps where nitrosamines could form:

- Amine-containing intermediates: Parts of the molecule, like the desosamine sugar, contain amines that may react with sodium nitrite or similar agents to create nitrosamines.

- Solvent breakdown: Common solvents such as DMF or NMP can degrade into amines like dimethylamine, which under certain conditions may produce NDMA.

- Reused solvents: Recycling solvents without proper cleaning may introduce secondary amines that form NDMA or NDEA in the presence of nitrites.

- Methylation and acylation: These reactions can leave behind amines that may turn into nitrosamines when exposed to nitrites.

- Catalyst-related amines: Some catalysts can create nitrosamine compounds if contaminated with nitrites.

The most likely nitrosamines in Azithromycin API production include NDMA, NDEA, N-nitrosomethylazithromycin, and N-nitrosodesosamine derivatives. Careful solvent handling, purification, and in-process checks are key to preventing them.

Read our nitrosamine impurities in pharmaceuticals guide

Nitrosamine Risk in Azithromycin Finished Products

Nitrosamine formation can also happen after the API stage, during tablet or capsule manufacturing:

- Excipient contamination: Ingredients such as starch or microcrystalline cellulose can contain tiny amounts of nitrites, which can react with amines in the drug.

- Storage degradation: Over time, the API can break down under heat, moisture, or acidic conditions, making it easier for nitrosamines to form.

- Packaging issues: Packaging materials, inks, or coatings that contain nitrites may cause nitrosamine formation in stored medicines.

Possible impurities at this stage include N-nitroso-desosamine derivatives, N-nitroso-methyl-desosamine, and other nitrosated azalide compounds. Using high-quality, nitrite-free excipients and packaging is essential for product safety.

Explore our NDSRIs in nitrosamine testing resource

Known Nitrosamine Impurities in Azithromycin

Regulators and laboratories have identified several nitrosamines that can appear in Azithromycin:

- NDMA (N-nitrosodimethylamine) – often linked to solvent breakdown.

- NDEA (N-nitrosodiethylamine) – can come from diethylamine contamination.

- N-nitrosomethylazithromycin – formed by nitrosation of tertiary amines.

- N-nitrosodesosamine derivatives – created from the secondary amine in desosamine.

- Nitrosated azalide macrocycle derivatives – can develop during storage with nitrite exposure.

Using advanced testing methods ensures these impurities stay below safe limits.

See our acceptable intake limits for nitrosamines

Conclusion

Nitrosamine Testing in Azithromycin is not just a regulatory requirement—it is essential for protecting patient health. By managing high-risk production steps, controlling solvents, reducing amine-rich intermediates, and ensuring nitrite-free excipients and packaging, drug makers can significantly cut the risk of NDMA, NDEA, and other NDSRIs. Laboratories like ResolveMass Laboratories Inc. provide expert testing, regulatory guidance, and quality assurance to help meet FDA, EMA, and Health Canada standards. Preventing nitrosamine contamination shows a strong commitment to producing safe, reliable medicines.

Contact our nitrosamine analysis laboratory today

FAQs on Nitrosamine Testing in Azithromycin

Nitrosamine impurity in Azithromycin is a type of unwanted chemical that can form during manufacturing or storage. These substances are considered harmful because some are linked to cancer risk in humans. They can appear in both the raw drug material (API) and the finished medicine if certain chemicals or conditions are present.

Nitrosamine Testing in Azithromycin is essential because these impurities are considered possible human carcinogens. Testing ensures the medicine meets strict global safety regulations and protects patients from harmful chemical exposure. Without this step, contaminated products could reach the market, posing serious health risks.

The most common nitrosamines found in Azithromycin API include NDMA, NDEA, N-nitrosomethylazithromycin, and N-nitrosodesosamine derivatives. These can form during certain manufacturing steps or storage, so they are closely monitored using advanced laboratory methods.

Yes. If recycled solvents contain leftover secondary or tertiary amines, they can react with nitrites to produce nitrosamines. This is why proper cleaning, testing, and solvent handling are critical to preventing contamination during Azithromycin manufacturing.

NDSRIs, or Nitrosamine Drug Substance Related Impurities, are nitrosamines that form directly from the drug’s own chemical structure. In Azithromycin, certain nitrogen-containing parts of the molecule can undergo nitrosation, creating unique impurities that need special detection methods.

Yes. Most regulatory agencies require nitrosamine testing for every production batch of Azithromycin. This ensures any contamination is detected early, maintaining compliance with safety limits and preventing unsafe medicine from reaching patients.

Yes. Health authorities like the FDA, EMA, and Health Canada set strict acceptable daily intake (ADI) limits for each nitrosamine. These limits are based on safety studies and must be met before the medicine can be approved for distribution.

Manufacturers can reduce risk by controlling raw materials, using nitrite-free excipients, avoiding contaminated solvents, and improving packaging quality. Partnering with specialized labs for Nitrosamine Testing in Azithromycin ensures compliance with regulatory expectations.

Read our nitrosamine risk assessment guide

References

- European Medicines Agency. (2025, July). European Medicines Regulatory Network’s response to nitrosamine impurities. European Medicines Agency. https://www.ema.europa.eu/en/human-regulatory-overview/post-authorisation/referral-procedures-human-medicines/nitrosamine-impurities

- Health Canada. (2025, August 1). Nitrosamine impurities in medications: Guidance. Government of Canada. https://www.canada.ca/en/health-canada/services/drugs-health-products/compliance-enforcement/information-health-product/drugs/nitrosamine-impurities/medications-guidance.html