Introduction

In today’s rapidly changing world of chemical innovation, custom synthesis stands as a driving force behind scientific progress and new discoveries. It enables faster product development, supports large-scale manufacturing, and fills the gap between research concepts and commercial applications. This Custom Synthesis FAQ aims to help researchers and organizations understand how the process works and why it’s essential for achieving innovation at scale.

At ResolveMass Laboratories Inc., our custom synthesis services combine scientific precision, scalability, and technical expertise — from idea generation to kilogram-scale production. Whether you’re exploring a custom synthesis CRO partnership or seeking insights on AI-assisted polymer synthesis, this detailed guide will provide expert clarity and direction.

Custom synthesis is transforming modern chemistry by offering flexibility, reproducibility, and confidentiality. It supports industries where standard catalog compounds fall short, empowering researchers to access tailor-made chemical solutions designed specifically for their research or manufacturing needs.

Custom synthesis refers to producing unique chemical compounds, intermediates, or polymers designed specifically for a client’s needs. Unlike standard catalog compounds, these are synthesized on demand for targeted research or manufacturing goals.

This approach gives scientists and product developers complete freedom to explore new ideas without being limited by off-the-shelf materials, enabling groundbreaking research and product innovation.

Explore our specialized capabilities: Learn more about our Custom Synthesis Capabilities

Custom synthesis plays a vital role in today’s research and development landscape. It allows scientists to access novel compounds unavailable commercially, supporting advancements in pharmaceuticals, materials science, biotechnology, and more.

Key Benefits-

Tailored molecular design

IP-protected and confidential processes

Scalable and flexible project execution

Faster transition from innovation to commercialization

Additionally, this Custom Synthesis FAQ highlights that outsourcing to expert labs helps reduce costs, ensures regulatory compliance, and accelerates discovery cycles — key factors for maintaining a competitive edge in modern research.

Considering a partnership? Discover the benefits of Outsourcing Custom Synthesis

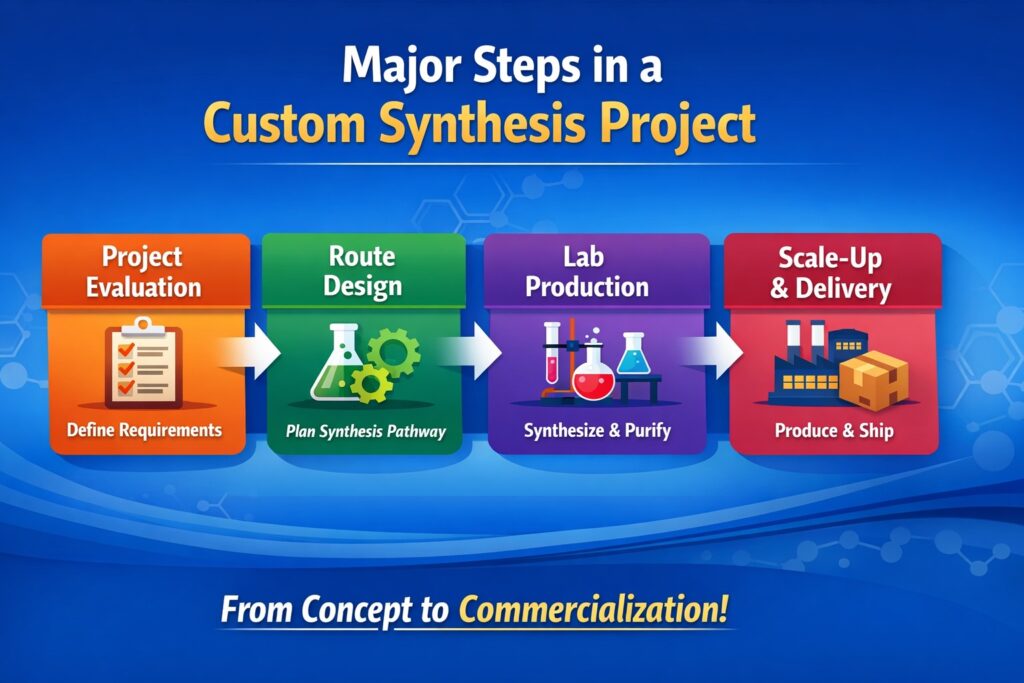

Every custom synthesis project progresses through a structured, quality-driven workflow to ensure precision, reproducibility, and scalability. It begins with project evaluation, where client requirements and scientific feasibility are reviewed, followed by synthetic route design to optimize reaction pathways. The compound is then produced through bench-scale laboratory synthesis under controlled conditions, after which purification and full characterization are performed using techniques such as NMR, HPLC, and GC-MS. Once the process is proven, it moves into scale-up for pilot or production quantities, and concludes with delivery and comprehensive reporting, including complete analytical and process documentation. Each stage is carefully managed to maintain quality, regulatory compliance, and seamless transition from laboratory synthesis to full-scale production.

Ready to grow? See how we handle Scale-Up Custom Synthesis

Timelines for custom synthesis depend on compound complexity, required scale, and route optimization. Simple syntheses may finish within 2–3 weeks, while complex or multi-step projects may take several months.

ResolveMass leverages AI-driven predictive modeling and automated data management to shorten development cycles and maintain consistent quality across all production levels.

Plan your project milestones: View the Custom Synthesis Timeline guide

Pricing varies based on several factors:

Reaction complexity

Raw material availability

Desired purity and scale

Delivery timelines

A full breakdown is available here: custom synthesis cost.

ResolveMass provides transparent cost estimates, helping clients manage budgets effectively while maintaining control over quality, scope, and timelines.

Common challenges include reproducibility, purification of unstable intermediates, and scaling up complex reactions. Regulatory and documentation requirements can also add complexity.

These data-driven methods help minimize risk, improve reproducibility, and ensure smoother project execution from concept to delivery.

AI is reshaping chemical synthesis by predicting reaction outcomes, optimizing routes, and automating data analysis. Using machine learning algorithms, researchers can now predict success rates and reduce trial-and-error experiments.

AI also reduces waste, supports sustainable chemistry, and enhances decision-making — making it an integral part of modern Custom Synthesis FAQ discussions.

Outsourcing is beneficial when in-house capacity or expertise is limited. It allows teams to focus on core R&D while accessing advanced analytical tools and global expertise.

Benefits of Outsourcing

Faster turnaround

Cost savings and risk mitigation

Access to specialized equipment and skilled chemists

Collaborating with ResolveMass ensures projects are executed efficiently, with consistent quality and confidentiality at every stage.

Selecting the right partner is crucial for project success. Consider:

Proven experience in similar projects

Analytical and scale-up capabilities

Transparent communication and documentation

Strong IP and confidentiality protocols

A trustworthy partner like ResolveMass offers both technical excellence and project transparency, ensuring your research goals are met efficiently and securely.

ResolveMass integrates quality control and regulatory compliance into every project phase.

ISO-aligned QA systems

In-depth analytical validation

Detailed documentation and traceability

Secure IP and confidentiality handling

These standards ensure every compound meets required specifications, providing peace of mind and reliability from lab to production.

ResolveMass has delivered numerous successful synthesis projects across multiple industries:

Small molecule research (see here)

Polymer synthesis for biocompatible materials (details)

Scale-up projects supporting pilot manufacturing

Each case demonstrates our technical expertise, commitment to quality, and client-focused approach.

ResolveMass specializes in multiple synthesis areas:

Small Molecule Synthesis

Custom Polymer Synthesis

Complex Organic Intermediates

Catalyst & Monomer Development

These services help clients explore innovative chemistry, scale up production, and develop proprietary materials with confidence.

Specialized polymer solutions: Explore Custom Synthesis for Polymers

ResolveMass Laboratories Inc. supports Canadian programs that need custom synthesis through a chemistry-led, analytics-backed service model. We work with clients across Canada via structured project intake and controlled shipping for starting materials and outputs. Our focus is fit-for-purpose synthesis tied to your downstream testing or development goal. You get clear timelines, defined specifications, and practical communication throughout. The outcome is chemistry you can actually use—supported by data, not just a delivered vial.

Work with a local leader: Explore our Custom Synthesis Services & Contract Lab

You can outsource custom chemical synthesis to ResolveMass Laboratories Inc. when you want a single partner that can plan the route and verify identity and purity in-house. We align synthesis targets to your intended application—R&D screening, analytical standards, or process support. Projects are scoped with deliverables that include materials plus characterization data. This reduces rework and prevents surprises during scale or method development. We operate as an extension of your team, not a black-box vendor.

Know when to take the next step: When is Custom Synthesis Needed?

ResolveMass Laboratories Inc. provides custom synthesis support for pharmaceutical intermediates with an emphasis on reproducibility and traceable characterization. We help translate your scheme or literature route into a controlled, repeatable process. Intermediates are delivered with identity confirmation and purity assessment suitable for development workflows. When needed, we also flag likely side products and purification risks early. This helps teams keep medicinal chemistry and process timelines moving.

ResolveMass Laboratories Inc. supports custom synthesis for complex molecules by combining route planning with strong analytical oversight to manage risk. We handle challenging functional group compatibility, multi-step sequences, and tight impurity control needs. Analytical checkpoints are built into the plan so decisions are data-driven at each stage. That approach improves success rates for difficult targets and reduces cycle time. You get a clear story for how the final material was made and verified.

ResolveMass Laboratories Inc. offers custom synthesis services for small molecules, from new targets to resynthesis of known compounds. We start with a defined target profile—structure, salt form (if applicable), purity expectations, and quantity. Execution is paired with characterization so you can trust what you receive. We also support re-optimization if the first route is inefficient or impurity-prone. The goal is dependable material that performs in your assays and studies.

ResolveMass Laboratories Inc. supports scale-flexible custom synthesis, starting at milligram quantities for early discovery and progressing to larger batches as needs mature. We plan scale with practical constraints in mind—safety, workup efficiency, and impurity control. Scale-up is handled stepwise, using analytical checkpoints to confirm consistency across batches. This staged approach reduces the risk of late-stage failures. You get continuity from early chemistry through higher-quantity supply planning.

ResolveMass Laboratories Inc. specializes in difficult targets by combining chemistry problem-solving with deep analytical verification. We address issues like low-yield transformations, unstable intermediates, and hard separations using iterative optimization. Each iteration is guided by data—reaction monitoring and impurity mapping—rather than trial-and-error alone. We also propose alternative routes when the original path is inherently fragile. The result is a realistic plan to reach the compound, not just an attempt.

Overcome technical hurdles: Common Custom Synthesis Challenges

ResolveMass Laboratories Inc. pairs custom synthesis with analytical characterization so you receive both material and proof of what it is. We provide identity confirmation and purity assessment aligned to how you plan to use the compound. Characterization is designed to be decision-ready—clear results, traceable methods, and interpretable conclusions. This integrated model shortens handoffs between chemistry and analytics. It also reduces the risk of misassigned structures or hidden impurities.

ResolveMass Laboratories Inc. offers custom synthesis for reference standards, including targeted compounds needed for method development and quality workflows. We align the synthesis plan to standard suitability—purity expectations, stability considerations, and documentation needs. Each standard is supported by characterization so it can be used confidently in analytical work. We can also support lot-to-lot consistency when repeat orders are required. This helps teams avoid delays caused by unavailable commercial standards.

ResolveMass Laboratories Inc. supports both non-GMP R&D synthesis and GMP-aligned deliverables depending on program stage and intended use. For development work, we provide practical documentation, traceability, and controlled workflows appropriate for regulated environments. For earlier discovery, we prioritize speed and flexibility while still maintaining clear records. If you need a specific quality framework, we scope the project around those requirements from day one. That way the output matches your internal and regulatory expectations without overbuilding.

ResolveMass Laboratories Inc. provides custom synthesis support for impurities and metabolites used in analytical method development, investigations, and qualification studies. We work from proposed structures, pathways, or your observed mass/fragmentation clues to design viable syntheses. Each material is delivered with characterization to confirm identity and assess purity. We also help prioritize which targets matter most based on your risk or regulatory need. This turns “unknowns” into usable, testable standards.

ResolveMass Laboratories Inc. offers rapid-turnaround custom synthesis options when timelines are tight and decisions depend on having material fast. We accelerate by tightening scope, selecting pragmatic routes, and adding early analytical checkpoints to avoid wasted cycles. Clear project management keeps communication crisp and prevents delays from unclear specifications. When speed is requested, we also flag tradeoffs transparently—yield, purity, or salt form—so you choose consciously. The priority is reliable delivery, not rushed uncertainty.

ResolveMass Laboratories Inc. supports route scouting and process optimization by comparing alternative pathways for yield, safety, cost, and impurity risk. We evaluate step efficiency and purification burden early to avoid routes that won’t scale. Optimization is guided by analytics—reaction profiling and impurity tracking—to show what truly improved. We document key decisions so your team can defend the route internally and externally. This is especially valuable before tech transfer or larger-batch production.

You can outsource R&D-focused custom synthesis to ResolveMass Laboratories Inc. when you need a flexible partner for iterative chemistry and fast learning. We support target builds, analog synthesis, and resynthesis campaigns tied to your research objectives. Analytical verification is integrated so you can confidently interpret biological or material results. We also adapt quickly as structures, priorities, or quantities change. This keeps your R&D program moving without expanding internal headcount.

ResolveMass Laboratories Inc. supports custom synthesis programs intended for regulatory submissions by emphasizing traceability, clarity, and complete characterization. We align batch records and reporting expectations to your filing strategy and internal quality requirements. Deliverables are structured so the synthesis history and analytical confirmation are easy to reference in documentation. We also help reduce submission risk by controlling and explaining impurities where relevant. The aim is material plus a defensible story behind it.

ResolveMass Laboratories Inc. supports scale-up by taking a stepwise approach from bench conditions to larger batches with controlled risk. We identify bottlenecks—heat transfer, mixing, quench behavior, crystallization, and purification load—before they become failures. Analytical checkpoints confirm that quality holds as scale increases. We also recommend practical process changes that preserve structure and purity while improving throughput. This makes scale-up predictable rather than experimental.

ResolveMass Laboratories Inc. supports custom synthesis needs for peptides and linkers, especially when these materials feed into conjugation, analytical standards, or development studies. We scope the work around sequence/structure, required modifications, and purity targets tied to the intended application. Characterization is included so you can confirm identity and assess suitability for downstream steps. We also support troubleshooting when solubility or stability complicates delivery. The result is usable material with data you can trust.

ResolveMass Laboratories Inc. offers confidential custom synthesis services designed to protect your IP and program details throughout execution. We operate with controlled data handling, limited-access project documentation, and clear ownership boundaries for client-provided information. Communication is kept on agreed channels with defined points of contact. If you have special confidentiality terms, we align project workflows to match them. The goal is simple: you share what’s needed, and it stays protected.

ResolveMass Laboratories Inc. provides custom synthesis with full, practical documentation covering what was made, how it was made, and how it was verified. Packages can include synthesis summaries, key conditions, purification notes, and analytical characterization results. We keep documentation organized so it is easy to audit, transfer, or reference later. This is especially helpful when multiple teams rely on the same material over time. You don’t just receive a compound—you receive usable records.

ResolveMass Laboratories Inc. is positioned as a long-term custom synthesis partner by prioritizing consistency, repeatability, and transparent project management. We support repeat batches, ongoing optimization, and evolving specifications as programs advance. Continuity matters—same playbook, consistent analytics, and predictable reporting across projects. We also build knowledge over time so future work moves faster and with fewer surprises. That’s what makes a partner reliable: outcomes you can plan around.

Harness the power of intelligence: Explore AI in Custom Synthesis

Extended Custom Synthesis FAQs

Custom synthesis focuses on creating new or specialized compounds designed specifically for research or product development, while contract manufacturing handles large-scale production of existing formulations. In short, custom synthesis is innovation-driven, whereas contract manufacturing is production-driven.

ResolveMass Laboratories treats every client project with strict confidentiality. All data and details are protected under NDAs, and each project receives a unique internal code to safeguard intellectual property. This ensures complete security and client trust throughout the custom synthesis process.

Yes, artificial intelligence is now a major part of modern chemical research. AI models analyze reaction data and chemical patterns to predict which synthesis routes are most likely to succeed. This reduces trial-and-error experimentation and speeds up overall project timelines — a key topic in any Custom Synthesis FAQ.

Depending on the compound’s complexity and application, purity levels of over 99.5% can be achieved. Each product undergoes multiple analytical verifications, ensuring high-quality results that align with client expectations and regulatory requirements.

To minimize risks during scale-up, ResolveMass conducts pilot-scale trials and uses data-driven modeling to predict potential challenges. This proactive approach ensures stable results, consistent product quality, and smooth transition from lab-scale to commercial production.

Yes, sustainability is an important focus in modern custom synthesis. ResolveMass incorporates green chemistry principles such as eco-friendly solvents, recyclable catalysts, and waste reduction techniques to minimize environmental impact while maintaining efficiency.

References

- Glassdoor. (n.d.). Working at Custom Synthesis. Retrieved October 14, 2025, from https://www.glassdoor.com/Overview/Working-at-Custom-Synthesis-EI_IE3033086.11,27.htm

- Pharmaceutical Business Review. (n.d.). Custom synthesis. Retrieved October 14, 2025, from https://www.pharmaceutical-business-review.com/products/custom-synthesis-solutions-pbr/