Summary

- Deuterated aromatic compounds improve OLED lifetime and stability by replacing hydrogen with deuterium, strengthening molecular bonds and reducing degradation, burn-in, and luminance loss.

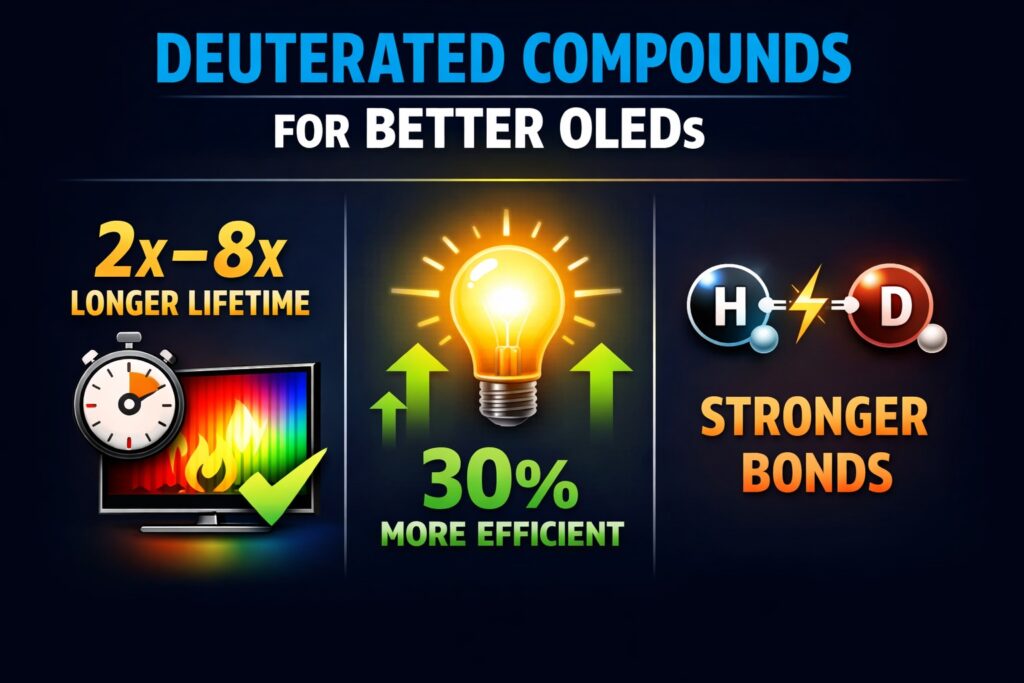

- They enhance performance by increasing efficiency, reducing heat generation, and delivering up to 2–8× longer operational lifetime and ~30% higher luminous efficiency.

- The Kinetic Isotope Effect lowers molecular vibration and makes bonds harder to break, which is especially important for stabilizing high-energy blue OLED emitters.

- Advanced synthesis and electronic-grade purification are required to achieve high isotopic purity and ensure reliable, long-term device performance.

- Using deuterated materials across multiple OLED layers further improves charge balance, durability, and overall device lifetime.

- Demand is growing rapidly as deuterated materials enable brighter, more energy-efficient, and longer-lasting displays for modern electronics.

Introduction:

Deuterated Aromatic Compounds for OLED are now recognized as one of the most effective solutions for improving the lifetime and stability of organic light-emitting displays. These advanced materials use the Kinetic Isotope Effect to strengthen molecular bonds and increase resistance to electrical and thermal stress during long operating hours. By carefully replacing hydrogen atoms with the heavier isotope deuterium, weak points in the molecule become more stable. This slows down chemical breakdown, reduces luminance loss, and minimizes burn-in issues in high-resolution displays.

The shift from traditional hydrogen-based materials to custom-synthesized Deuterated Aromatic Compounds for OLED is driven by the natural instability of organic molecules under high energy conditions. In standard OLED systems, the carbon-hydrogen (C–H) bond is often the weakest link, especially in blue-emitting layers where energy levels are very high. Through precise regioselective deuteration, these sensitive positions are reinforced without changing the core electronic structure of the material. As a result, the molecular framework becomes more resistant to oxidation, bond cleavage, and long-term thermal stress during device operation.

Explore our specialized synthesis services for display technology: Deuterated Labelled Chemical Synthesis Company in United States

Beyond durability, deuterated aromatic materials also offer clear performance benefits. Because deuterium is heavier than hydrogen, it lowers molecular vibration and reduces zero-point energy. This limits non-radiative decay, where energy is lost as heat instead of light. The result is improved external quantum efficiency (EQE), better color stability, and reduced power consumption in both smartphones and large OLED television panels. Over time, this improved efficiency lowers internal heating and reduces stress on surrounding device layers.

Access high-quality benzene-d6 for your next project: Buy Deuterated Benzene-D6 for OLED

Performance comparisons clearly highlight the advantages of isotopic substitution in OLED systems:

| Performance Metric | Standard Hydrogenated Material | Deuterated Aromatic Compound | Impact on Device |

|---|---|---|---|

| Operational Lifetime (LT95) | Baseline | 2x to 8x Improvement | Reduced burn-in and replacement frequency |

| Luminous Efficiency | Baseline | ~30% Increase | Lower power consumption for mobile devices |

| Bond Energy (C-X) | ~413 kJ/mol | 414–418 kJ/mol | Enhanced thermal and chemical stability |

| Vibrational Loss | High (High Frequency) | Low (Suppressed) | Reduced non-radiative recombination |

| Color Shift | Prone after 1,000 hrs | Stable over 20,000 hrs | Consistent display quality over time |

These improvements are especially important for high-brightness television panels and professional monitors, where color accuracy and long service life are critical requirements. Stable materials directly translate into fewer display failures and better customer satisfaction.

Molecular Mechanics of Deuterated Aromatic Compounds for OLED Stability

The enhanced stability of Deuterated Aromatic Compounds for OLED comes from changes in molecular vibration and energy surface behavior. In high-energy OLED systems, especially blue fluorescent and phosphorescent devices, molecules can reach unstable excited states. When this happens, bond breaking and degradation may occur. Deuterium substitution slightly modifies the potential energy surface, making it harder for molecules to reach unstable geometries that lead to permanent damage.

Learn more about the role of isotopes in advanced materials: Stable Isotope Labeled Compounds

During normal operation, OLED emitters switch between ground and excited states thousands of times every second. Even a small improvement in bond strength can significantly reduce long-term wear. Deuteration lowers vibrational intensity and stabilizes excited states, which reduces chemical breakdown over time. These molecular-level improvements result in measurable gains in LT80 and LT90 performance in commercial OLED testing.

The Kinetic Isotope Effect (KIE) and Bond Energetics

The Kinetic Isotope Effect is the scientific principle behind the success of Deuterated Aromatic Compounds for OLED. Deuterium has nearly double the mass of hydrogen, which lowers the vibrational frequency of the carbon–deuterium (C–D) bond compared to the carbon–hydrogen (C–H) bond. This change reduces zero-point energy and makes the bond harder to break.

The vibrational relationship is described by the harmonic oscillator equation:

ν = (1 / 2π) √(k / μ)

In this equation, k is the bond force constant and μ is the reduced mass. When hydrogen is replaced by deuterium, the reduced mass increases and vibrational frequency decreases. As a result, more energy is needed to break the C–D bond. In OLED devices, where materials are constantly exposed to electrical excitation, even small increases in bond energy can greatly slow chemical degradation.

This effect is particularly important in blue emitters, where exciton energy is highest and molecular damage is more likely. Over thousands of hours of operation, the cumulative benefit becomes significant.

Understand the technical foundations of these materials: Deuterated Polymers: A Cornerstone Guide to Synthesis and Applications

Suppression of Non-Radiative Decay in Deuterated Aromatic Compounds for OLED

Non-radiative decay is one of the main reasons for efficiency loss in OLED devices. In hydrogen-based materials, high-frequency C–H vibrations can couple with electronic transitions. This causes energy to be released as heat instead of visible light, reducing brightness and increasing device temperature.

When hydrogen atoms are replaced with deuterium, vibrational modes shift to lower energy levels. These lower vibrations are less likely to interact with excited electronic states. As a result, a larger portion of energy is released as light, improving brightness and overall device efficiency. Reduced heat generation also protects neighboring layers within the OLED stack, improving long-term reliability.

Find the right reagents for your electronic applications: Deuterated Reagents for Electronics

Conical Intersections and Dissociation Pathways

A key degradation mechanism in blue OLED systems involves high-energy excited states reaching conical intersections. These are points where two energy surfaces meet, allowing a rapid transition from a light-emitting state to a bond-breaking state. Once this transition occurs, permanent molecular damage may follow.

Deuteration helps reduce this risk by flattening the energy pathway toward dissociation. This makes it less likely for the molecule to reach unstable geometries. For Blue TADF emitters, which are especially sensitive to degradation, deuterium incorporation significantly improves operational stability. Materials such as deuterated carbazole-based systems show both high EQE and longer LT80 lifetimes under accelerated testing conditions.

Catalytic Synthesis of Deuterated Aromatic Compounds for OLED Building Blocks

The production of Deuterated Aromatic Compounds for OLED depends on advanced hydrogen–deuterium exchange (HDE) and organometallic synthesis methods. These techniques allow high isotopic purity and precise control of substitution sites. Transition metal catalysts such as iridium, palladium, and platinum are commonly used with deuterium sources like D₂O.

Maintaining high isotopic incorporation is essential because incomplete substitution lowers stability benefits. Reaction temperature, solvent purity, and catalyst selection must be carefully controlled to achieve electronic-grade quality. Industrial production also requires consistent batch reproducibility and minimal residual metal contamination.

Partner with experts for your custom molecule needs: Custom Deuterated Compounds

Homogeneous Iridium Catalysis

Homogeneous iridium catalysts are widely used due to their selectivity and compatibility with aromatic substrates. The catalyst [Cp*IrCl₂]₂ is frequently applied for site-specific deuteration of carbazole and indole derivatives used in OLED host and transport materials.

The reaction generally follows three key steps:

- Oxidative Addition – The C–H bond attaches to the iridium center.

- Ligand Exchange – Hydrogen is replaced with deuterium from the deuterium source.

- Reductive Elimination – The C–D bond forms and the catalyst regenerates.

This method can achieve high deuterium incorporation rates, often above 90% at selected positions. Such precision keeps the molecule’s electronic properties intact while increasing bond stability.

Heterogeneous Synthesis and Microwave-Assisted Flow Chemistry

For large-scale production, heterogeneous catalysts such as Pd/C and Pt/C are commonly used. These systems are easier to separate and scale for industrial manufacturing. Modern production also uses microwave-assisted flow reactors to increase efficiency and reduce processing time.

Compared to traditional batch reactors, microwave flow systems provide faster and more uniform heating. Reaction times can be reduced from nearly one hour to just a few minutes. This improves yield, reduces energy consumption, and supports sustainable manufacturing practices.

| Synthetic Parameter | Batch Method (Ref) | Flow-Type Microwave Reactor | Improvement Factor |

| Efficiency (1-Naphthol) | 27% (10 min) | 91% (3 min) | ~10x Higher Efficiency |

| Heating Time (200 °C) | 60 minutes | 1.5 minutes | 40x Faster Heating |

| Energy Consumption | Baseline | 30% Reduction | Improved Sustainability |

| Catalyst Separation | Manual Filtration | Continuous/Integrated | Simplified Process |

This approach supports scalable production of important OLED intermediates at pilot and commercial levels.

Purification of Electronic-Grade Deuterated Aromatic Compounds for OLED

Electronic-grade Deuterated Aromatic Compounds for OLED require much higher purity than standard laboratory-grade materials. Isotopic enrichment must typically reach at least 99.96 atom % deuterium. Metal contamination must be reduced to parts-per-billion levels to prevent charge trapping or exciton quenching.

Trace hydrogen content, residual catalysts, moisture, and halogen impurities must be tightly controlled. Even extremely small contamination levels can reduce OLED lifetime or create batch variation. High-performance analytical tools such as ICP-MS, high-resolution NMR, Karl Fischer titration, and mass spectrometry are used for strict quality verification.

Ensure your compounds meet strict analytical standards: Analytical Characterization of Deuterated Compounds

Distinguishing NMR-Grade from Electronic-Grade Materials

Standard NMR-grade solvents are not suitable for OLED production because they may contain residual hydrogen or trace metals. These impurities can act as degradation points within the device structure.

Electronic-grade materials must meet strict requirements:

- Isotopic Enrichment: ≥ 99.96 atom % D

- Trace Metals: < 10 ppb for Pd, Pt, Au

- Moisture: < 0.005% (50 ppm)

- Halogens (Br, Cl): Not detectable

ResolveMass Laboratories follows these strict standards to ensure consistent performance in advanced display manufacturing. Reliable purity control directly supports long-term OLED device stability.

Advanced Purification and Handling Protocols

Reaching true electronic-grade purity requires much more than simple recrystallization techniques. The process begins with dissolving the material in carefully selected solvents, followed by repeated washing steps using ultra-high-purity water. Typically, this washing procedure is performed between 8 and 15 cycles to effectively remove ionic impurities and trace metal residues. After washing, adsorption-based drying is carried out with specialized chromatography columns under an inert gas atmosphere. This step removes remaining polar contaminants while maintaining the compound’s isotopic composition and structural stability.

The final stage of purification involves high-vacuum sublimation. Many OLED materials have melting points that are very close to their decomposition temperatures, which makes traditional distillation methods unsuitable. Sublimation allows the desired compound to transition directly from solid to vapor and then back to solid, separating it from non-volatile metal residues and unwanted organic by-products. This technique produces highly purified material that is appropriate for use in vacuum thermal evaporation (VTE) processes.

Quality verification is completed using advanced analytical instruments with very high sensitivity. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is applied to identify trace metal contamination at parts-per-billion (ppb) and even parts-per-trillion (ppt) levels. High-resolution ¹H and ²H Nuclear Magnetic Resonance (NMR) spectroscopy confirms isotopic enrichment and verifies the absence of remaining proton signals. Karl Fischer titration is used to accurately measure moisture content. In addition, LDI-TOF mass spectrometry analyzes fragmentation behavior to confirm that no material degradation has occurred during synthesis or sublimation.

Systemic Integration in OLED Architecture: EML, HTL, and ETL

The greatest gains in device durability are observed when deuterated aromatic compounds for OLED are applied across the full organic layer structure. This includes both the host and dopant materials inside the emissive layer, along with the hole and electron transport layers. While the Emissive Layer (EML) is the main target for deuteration efforts, research shows that a unified, multi-layer approach can increase LT90 performance by as much as eight times in blue fluorescent OLED devices.

Browse our full inventory of deuterated solutions: Availability of All the Deuterated Chemicals

The Emissive Layer: Hosts and Dopants

Inside the EML, anthracene-based host materials are commonly accepted as the benchmark for blue light emission. When these host compounds are deuterated, molecular packing becomes tighter and reorganization energy is lowered. These structural improvements support better charge carrier mobility and reduce the operating voltage needed to drive the device.

The term external deuteration effect describes how a deuterated host matrix stabilizes the guest dopant molecule. By creating an environment with reduced vibrational energy, the host limits non-radiative decay processes in the dopant. This leads to sharper emission profiles and enhanced color purity, often reflected in improved CIEy values. In deep-blue PhOLEDs (Phosphorescent OLEDs), the use of deuterated exciplex-forming host systems has delivered LT95 lifetimes reaching 290 hours under high-brightness conditions, which is nearly 60 percent longer than comparable non-deuterated systems.

Hole and Electron Transport Layers

The Hole Transport Layer (HTL) is exposed to considerable thermal load because it is positioned next to the anode. Deuterated versions of common HTL materials such as NPB and TCTA show stronger morphological stability and greater resistance to hole trapping, a factor that often leads to efficiency roll-off during prolonged use.

Within the Electron Transport Layer (ETL), deuterated analogues of materials like BPhen or Alq3 improve electron injection capability and offer better protection against radical-driven oxidation. When the ETL and HTL are optimized alongside the EML, the charge recombination zone stays balanced and stable for extended operating periods that can exceed tens of thousands of hours.

| Device Component | Primary Material | Impact of Deuteration | Lifetime Gain (LT90) |

| EML Host | Anthracene-based | Reduced exciton quenching; denser packing | 4x Improvement |

| EML Dopant | Ir-complex / TADF | Suppressed bond dissociation; PES flattening | 2x Improvement |

| Transport Layers | NPB / BPhen | Better charge balance; oxidative resistance | 1.6x Improvement |

| Complete Stack | Systemic All-Layer | Maximized Kinetic Isotope Effect (KIE) | 8x Improvement |

Market Evolution and Commercial Demand for Deuterated Aromatic Compounds for OLED

The demand for Deuterated Aromatic Compounds for OLED continues to grow as display manufacturers focus on higher brightness and longer lifetimes. Automotive displays, medical monitors, and 8K televisions require materials that can operate reliably for many years.

The global OLED materials market is expanding rapidly, driven by consumer electronics and next-generation panel technologies. High-purity deuterated materials are becoming a key investment area for major display manufacturers. As production capacity increases, large-scale adoption of deuterated materials is expected to accelerate further.

The “OLED EX” and the Blue Bottleneck

The introduction of OLED EX technology demonstrated how deuterium incorporation can increase brightness by about 30% while maintaining color stability. This marked an important milestone in isotopic engineering for commercial displays.

However, deep-blue emitters remain the most challenging component in OLED systems. Deuteration is currently one of the most practical solutions for extending the operational lifetime of blue fluorescent and TADF materials beyond 20,000 hours. Continued innovation in this area is essential for future premium display technologies.

Sustainability and Circular Economy Initiatives

Although the custom synthesis of deuterated materials requires advanced processing, sustainability programs are improving economic feasibility. ResolveMass Laboratories supports solvent recovery and isotopic re-enrichment strategies to reduce waste and production costs.

These initiatives allow manufacturers to recycle valuable deuterated solvents and maintain supply stability. Extended panel lifetimes also reduce electronic waste, supporting global environmental goals. Sustainable production practices are becoming increasingly important in advanced electronics manufacturing.

Conclusion

The future of high-performance display technology strongly depends on Deuterated Aromatic Compounds for OLED. Through controlled hydrogen replacement, the Kinetic Isotope Effect strengthens molecular bonds, reduces vibrational losses, and limits non-radiative decay. Achieving electronic-grade purity with extremely low contamination levels is critical for maximizing OLED lifetime, especially in deep-blue emissive layers.

As the OLED industry continues to grow, full-stack integration of deuterated materials, advanced catalytic synthesis, and sustainable recovery programs will play a central role in delivering brighter, more energy-efficient, and burn-in-resistant displays.

For technical consultation regarding custom synthesis, electronic-grade standards, or bulk supply of deuterated building blocks, please contact ResolveMass Laboratories:

Technical Consultation: Contact us

Frequently Asked Questions (FAQs)

Custom synthesis is viewed as the gold standard because it targets the main chemical reason behind OLED degradation, which is the breaking of carbon–hydrogen bonds under electrical stress. By replacing hydrogen with deuterium, the bond becomes stronger due to the Kinetic Isotope Effect (KIE). This slows down chemical breakdown and significantly improves operational lifetime. As a result, device stability is enhanced at the molecular level rather than through surface-level modifications.

NMR-grade materials usually provide around 99.5% isotopic purity and may contain trace metal impurities at parts-per-million (ppm) levels. In contrast, electronic-grade compounds require at least 99.96% deuterium enrichment and metal contamination below 10 parts per billion (ppb). These stricter standards are necessary to protect OLED devices from charge trapping and early failure. Higher purity directly supports longer device lifespan and consistent performance.

Studies show that applying deuteration across multiple layers, including the host, emitter, and transport layers, can dramatically improve durability. In blue fluorescent OLED systems, LT90 values have increased by up to eight times compared to non-deuterated designs. This means the display maintains 90% of its brightness for a much longer period. The improvement is especially important for high-energy blue emitters.

In most cases, deuteration does not change the fundamental emission wavelength of the material. Instead, it can improve color quality by reducing unwanted side emissions and narrowing the Full Width at Half Maximum (FWHM). This leads to sharper spectral output and better color precision. As a result, displays can achieve improved visual clarity without shifting the intended color balance.

Potential Energy Surface (PES) flattening describes how deuterium substitution slightly reshapes the molecule’s energy profile. The modified surface makes it harder for the molecule to reach unstable geometries that lead to bond breakage. This reduces the likelihood of reaching conical intersection points associated with degradation. In simple terms, the molecule becomes more resistant to destructive excited-state transitions.

The Emissive Layer (EML), particularly the blue host and emitter materials, gains the most benefit because it operates under the highest energy conditions. However, the Hole Transport Layer (HTL) and Electron Transport Layer (ETL) also play critical roles in maintaining charge balance. Deuterating these layers improves overall device stability and reduces efficiency loss over time. A full-stack approach delivers the best long-term results.

Microwave-assisted flow processing significantly increases reaction speed and efficiency compared to traditional batch methods. Heating times are reduced from hours to just minutes, while yields can increase up to tenfold. This makes large-scale production of high-purity deuterated intermediates more practical. The method also reduces energy use and improves process consistency.

Reference

- Whitlow, J., Jia, Z., Wang, Y., Fang, C., Kim, J., & Brown, K. R. (2023). Quantum simulation of conical intersections using trapped ions. Nature Chemistry, 15(11), 1509–1514. https://doi.org/10.1038/s41557-023-01303-0

- Dhillon, P., Kathiravan, S., Wiklander, J. G., & Nicholls, I. A. (2025). Iridium/silver-catalyzed H/D exchange for perdeuteration of indoles and site-selective deuteration of carbazoles: Application in late-stage functionalization. Journal of Organic Chemistry, 90(33), 11791–11801. https://doi.org/10.1021/acs.joc.5c00702

- Kwon, H., Oh, S., Park, S., Park, S., Lee, H., & Park, J. (2024). Highly efficient blue host compound based on an anthracene moiety for OLEDs. Applied Sciences, 14(13), 5716. https://doi.org/10.3390/app14135716

- Liu, X., Li, Q., Sun, W., Zang, C., & Yu, Q. (2013). Pre-purification method before sublimation and purification of OLED (organic light emitting diode) material (CN103449947A). Yantai Derun Liquid Crystal Materials Co., Ltd. https://patents.google.com/patent/CN103449947A/en