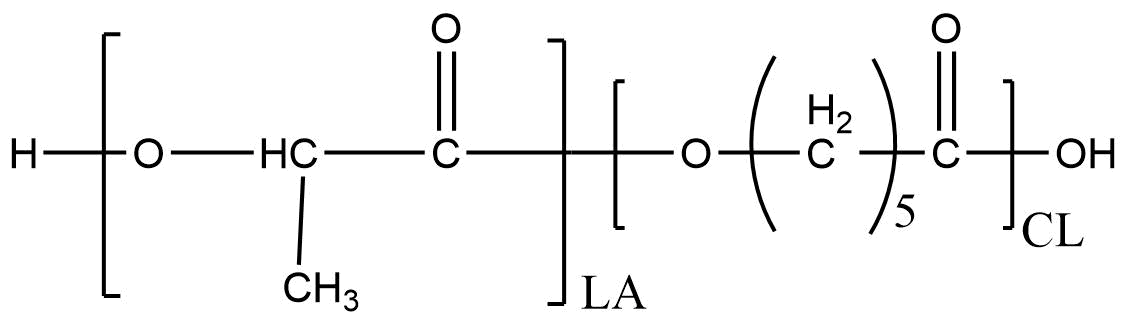

Poly(D,L-lactide)-b-poly(caprolactone) | Ratio: (PLCL 75:25) | Mw: 50000-120,000

OVERVIEW

Poly(D,L-lactide)-b-poly(caprolactone) | Ratio: (PLCL 75:25) | Mw: 50000-120,000 is a versatile, biodegradable, and biocompatible block copolymer engineered from two widely used aliphatic polyesters—poly(D,L-lactide) (PLA) and poly(caprolactone) (PCL). This specific formulation, PLCL 75:25 with a molecular weight range of 50,000–120,000, offers an optimal balance between mechanical flexibility and controlled degradation behavior. Its tunable physicochemical properties make it highly suitable for advanced biomedical research, drug-delivery systems, tissue-engineering scaffolds, and formulation development.

At ResolveMass Laboratories Inc., we provide high-quality PLCL with controlled molecular weight distribution and batch-to-batch consistency, supporting innovators in biomaterials, regenerative medicine, and pharmaceutical development.

CHEMICAL INFORMATION

-

Chemical Name: Poly(D,L-lactide)-b-poly(caprolactone)

-

Abbreviation: PLCL (75:25)

-

Composition: 75% D,L-lactide block : 25% ε-caprolactone block

-

Molecular Weight Range: 50000-120,000 Da (custom Mw available on request)

-

Structure: Linear A-B block copolymer

-

CAS Number: Not assigned (copolymer; varies by configuration)

-

Chemical Family: Biodegradable aliphatic polyester block copolymers

The 75:25 ratio provides a unique interplay between the stiffness of PLA and the elasticity of PCL, resulting in a copolymer with intermediate mechanical properties and a moderate degradation rate—faster than PCL yet slower and more flexible than PLA.

KEY MATERIAL PROPERTIES

-

Biodegradable and Biocompatible: Suitable for biomedical and pharmaceutical use.

-

Tunable Mechanical Flexibility: Offers enhanced elasticity compared to pure PLA.

-

Controlled Degradation Profile: Degrades via hydrolytic cleavage of ester bonds, ideal for long-term or sustained-release applications.

-

Solubility: Soluble in common organic solvents such as dichloromethane (DCM), acetone, chloroform, and THF.

-

Thermal Behavior: Exhibits amorphous-to-semi-crystalline characteristics depending on molecular weight and block distribution.

-

Film-Forming Capability: Easily cast into thin films, microspheres, and scaffolds.

-

Low Cytotoxicity: Compatible with cell-based applications.

This balance of mechanical strength and pliability allows PLCL 50:50 to perform exceptionally well in soft tissue engineering and controlled drug-release matrices.

APPLICATIONS

Drug Delivery Systems

PLCL is widely used in formulation development for controlled and sustained release of small molecules, peptides, and biologics. Its intermediate degradation rate enables flexible release profiles spanning weeks to months. It is ideal for:

-

Injectable depots

-

Microspheres and nanospheres

-

Implantable drug-release matrices

-

Long-acting formulations

-

Transdermal patches and films

Tissue Engineering and Regenerative Medicine

The elasticity of PLCL 75:25 mimics the mechanical properties of soft tissues, making it a preferred material in:

-

Soft tissue scaffolds

-

Cartilage regeneration

-

Vascular tissue engineering

-

Nerve regeneration guides

-

3D-printed biomaterial constructs

Its biocompatibility and mechanical compliance support cell adhesion, proliferation, and differentiated tissue growth.

Medical Device and Implant Research

PLCL offers a balance between flexibility and structural stability, suitable for:

-

Resorbable sutures

-

Flexible implants

-

Wound-healing matrices

-

Injectable gels

Its degradation rate is suitable for mid-term resorbable devices where mechanical support is required temporarily.

Polymer Research & Custom Material Development

PLCL is frequently used in academic and industrial research involving:

-

Polymeric micelles

-

Surface modification

-

Hydrophobic–hydrophilic balance studies

-

Block copolymer self-assembly

-

Novel biomaterial design

Researchers value its ability to be tailored by adjusting molecular weight, lactide-to-caprolactone ratio, and block length distribution.

ADVANTAGES OF PLCL 75:25

-

Balanced mechanical properties ideal for soft and flexible constructs

-

Suitable for both in vitro and in vivo applications

-

Highly customizable molecular weight and end-group chemistry

-

Excellent processability for electrospinning, casting, molding, and 3D printing

-

Predictable hydrolytic degradation mechanism

-

Strong track record in biomaterial research and pharmaceutical formulation science

WHY CHOOSE RESOLVEMASS LABORATORIES INC.

ResolveMass Laboratories Inc. provides high-purity PLCL with precise molecular weight control, low residual monomers, and excellent reproducibility. Our materials are designed for researchers who require reliable performance in drug-delivery, biomedical engineering, and advanced polymer development. We support custom synthesis, tailored copolymer ratios, and project-specific technical guidance.

Read below Learn with Us Articles:

PLGA Nanoparticles Synthesis: A Step-by-Step Guide for Beginners

The Science Behind GPC: A Deep Dive into Analyzing PLA, PLGA, and PCL for Research

Reviews

There are no reviews yet.