Poly(ethylene glycol)-b-Poly(caprolactone) | mPEG: PCL (Mw 1500:50000)

OVERVIEW

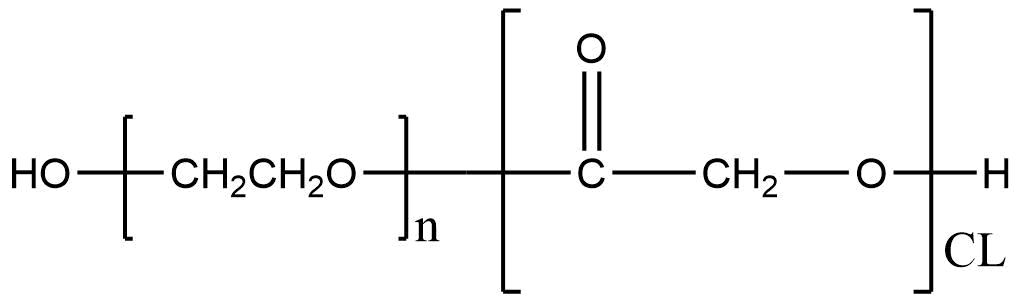

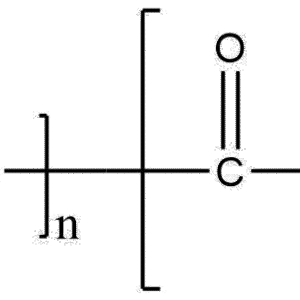

Poly(ethylene glycol)-b-Poly(caprolactone) | mPEG: PCL (Mw 1500:50000) is a biocompatible and biodegradable amphiphilic block copolymer widely used in advanced drug delivery, nanocarrier engineering, and regenerative medicine. The polymer combines a hydrophilic methoxy-PEG segment (Mw 1500) with a hydrophobic poly(caprolactone) block (Mw 50000), forming a versatile material that self-assembles into micelles, nanoparticles, or nanofibers depending on formulation conditions.

The unique molecular architecture enables controlled encapsulation of both hydrophilic and hydrophobic molecules, prolonged drug release, enhanced circulation half-life, and reduced clearance by the mononuclear phagocyte system. With excellent physicochemical tunability and FDA-recognized monomers, mPEG-PCL has become a preferred copolymer for translational research and pharmaceutical product development.

CHEMICAL INFORMATION

-

Chemical Name: Poly(ethylene glycol)-b-poly(ε-caprolactone)

-

Abbreviation: mPEG-PCL

-

Structure: ABA-type amphiphilic block copolymer with methoxy termination

-

Molecular Weights:

-

mPEG block: ~1500 Da

-

PCL block: ~50,000 Da

-

-

Physical Form: Typically off-white solid, waxy solid, or granules depending on degree of polymerization

-

Solubility:

-

Hydrophobic solvents: DCM, chloroform, THF — excellent

-

Polar solvents: methanol, ethanol — moderate

-

Aqueous media: forms micelles or nanoparticles above CMC

-

-

Thermal Behavior:

-

Semi-crystalline PCL block with low melting point (~55–60 °C)

-

PEG segment contributes flexibility and reduced crystallinity

-

KEY SYNONYMS

-

Methoxy poly(ethylene glycol)-b-poly(ε-caprolactone)

-

mPEG-b-PCL

-

PEG-PCL block copolymer

-

Poly(caprolactone)-graft-poly(ethylene glycol) (informal)

-

PEG-PCL amphiphilic copolymer

KEY FEATURES & PERFORMANCE ADVANTAGES

-

Amphiphilic Self-Assembly

The hydrophobic PCL block drives nanoparticle formation, while the PEG corona stabilizes colloidal structures in aqueous media, reducing aggregation and opsonization. -

Biodegradable & Biocompatible

Both PEG and PCL are recognized for excellent tolerability, hydrolytic degradability, and suitability for biomedical formulations. -

Improved Drug Loading Efficiency

The 50 kDa PCL segment provides a large hydrophobic domain for encapsulating poorly soluble APIs, small molecules, and lipophilic biologics. -

Extended Circulation Time

The PEG block (1.5 kDa) offers “stealth” properties that minimize protein adsorption and phagocytic uptake. -

Tunable Release Kinetics

PCL’s slow degradation rate enables sustained and controlled release over days to months, depending on formulation strategy. -

Excellent Film- and Fiber-forming Ability

Suitable for scaffolds, composite biomaterials, and regenerative applications.

APPLICATIONS

Drug Delivery Systems

mPEG-PCL is widely used for polymeric micelles, nanoparticles, and core-shell carriers for delivering hydrophobic small molecules, peptides, photosensitizers, and experimental therapeutics. The long hydrophobic chain (50,000 Da) enables high loading capacity, while the PEG corona stabilizes the colloidal form during circulation.

Controlled Release Formulations

The slow degradation of PCL makes this copolymer ideal for long-acting depots, injectable formulations, implantable matrices, and transdermal systems requiring prolonged release.

Nanomedicine & Encapsulation Technologies

mPEG-PCL is frequently applied in:

-

Nanoemulsions and polymeric nanocapsules

-

Hybrid lipid–polymer nanoparticles

-

Photothermal and photodynamic therapy carriers

-

Targeted delivery platforms when modified with ligands or peptides

Tissue Engineering & Regenerative Biomaterials

The mechanical strength and elasticity of the PCL block allow this copolymer to be used in:

-

Electrospun scaffolds

-

Hydrogels or cryogels

-

3D-printed biomaterials

-

Wound healing matrices

The PEG end group improves hydrophilicity, modulates protein adsorption, and enhances cell compatibility.

Biomedical Coatings & Surface Modification

mPEG-PCL provides non-fouling and biocompatible surface properties suitable for:

-

Medical device coatings

-

Biosensor surfaces

-

Anti-fouling layers

TECHNICAL ADVANTAGES FOR FORMULATION SCIENTISTS

-

Excellent batch-to-batch reproducibility when synthesized under controlled ROP conditions

-

Stable micellar structures even at low concentrations

-

Controllable crystallinity and thermal behavior

-

Low cytotoxicity profile

-

Ideal for combination studies with PLGA, PLA, PCL-PEG-PCL triblocks, or targeted copolymers

WHY CHOOSE RESOLVEMASS LABORATORIES INC.

ResolveMass Laboratories Inc. provides high-purity, precisely characterized mPEG-PCL (Mw 1500:50000) optimized for research, nanomedicine development, and preclinical formulation work. Each batch undergoes advanced spectroscopic and chromatographic verification to ensure accurate molecular weight, narrow PDI, and consistent performance in nanoparticle formation and encapsulation studies.

Read below Learn with Us Articles:

PLGA Nanoparticles Synthesis: A Step-by-Step Guide for Beginners

The Science Behind GPC: A Deep Dive into Analyzing PLA, PLGA, and PCL for Research

Reviews

There are no reviews yet.