Introduction: Why PLGA Polymer Grade Selection Makes or Breaks Your Formulation

The role of PLGA polymer grade in long-acting release formulation is the single most critical decision that determines whether your injectable product will succeed or fail in clinical development. At ResolveMass Laboratories Inc., we’ve repeatedly observed—through real-world PLGA microsphere case studies how improper PLGA selection leads to uncontrolled burst release, incomplete drug liberation, or premature degradation.

Often, the difference between a one-month and a three-month release profile comes down to molecular weight, lactide-to-glycolide ratio, and end-group functionality. This guide draws from our hands-on expertise in polymer science, PLGA reverse engineering for ANDA, and PLGA polymer characterization for generics to help you navigate PLGA-based formulation desig

Summary

Key Takeaways

- PLGA polymer grade directly determines drug release kinetics, with molecular weight and lactide:glycolide ratio being critical selection factors

- Selecting the wrong PLGA grade can lead to formulation failure, including burst release, incomplete drug release, or stability issues documented in multiple PLGA formulation stability studies

- ResolveMass Laboratories specializes in PLGA-based formulation development with extensive experience in polymer characterization and selection

- Key considerations include inherent viscosity, end-group chemistry, and degradation profile when choosing PLGA for long-acting injectables

- Proper analytical characterization ensures reproducible manufacturing and supports Q1/Q2 polymer equivalence assessment

- Custom PLGA modification strategies can address unique challenges in sustained-release and PLGA depot formulation development

1: What Is PLGA Polymer and Why Is Grade Selection Critical?

PLGA (poly(lactic-co-glycolic acid)) is a biodegradable, biocompatible polymer whose degradation rate controls drug release. The grade of PLGA defines its physicochemical properties, which directly influence microsphere formation, drug loading, and long-term stability—particularly in PLGA microsphere formulation and depot systems.

Key PLGA Grade Parameters

| PLGA Parameter | Impact on Long-Acting Release |

|---|---|

| Lactide:Glycolide Ratio | Controls degradation speed |

| Molecular Weight | Affects release duration |

| End Group Chemistry | Influences water uptake |

| Intrinsic Viscosity | Impacts microsphere formation |

| Polymer Architecture | Alters mechanical integrity |

👉 Bottom line: Two PLGA polymers with the same name but different grades can produce dramatically different release profiles—an issue frequently uncovered during PLGA scale-up investigations.

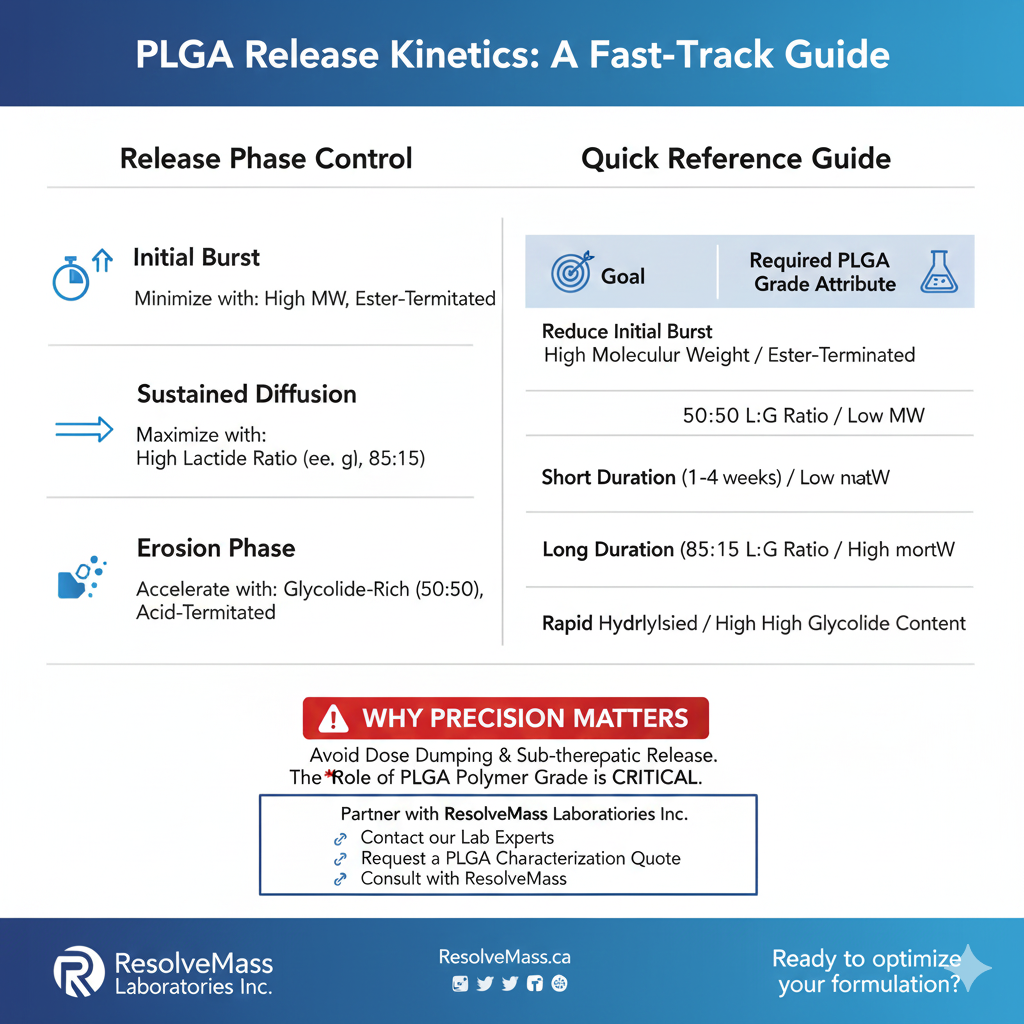

2: Role of PLGA Polymer Grade in Long-Acting Release Formulation Kinetics

The role of PLGA polymer grade in long-acting release formulation is most visible in drug release kinetics. PLGA controls release through a combination of diffusion and polymer erosion.

How PLGA Grade Affects Release Phases

Initial Burst Release

- Lower molecular weight PLGA → higher burst

- Acid-terminated PLGA → increased water uptake

Sustained Diffusion Phase

- Higher lactide content → slower diffusion

- Higher viscosity → denser polymer matrix

Erosion-Controlled Phase

- Glycolide-rich PLGA → faster bulk erosion

- End-group chemistry governs autocatalysis

Selecting the wrong PLGA grade can cause:

- Dose dumping

- Sub-therapeutic release

- Failed bioequivalence studies

—especially evident in long-acting reference products such as the Lupron Depot PLGA reverse-engineering case study.

3: Molecular Weight and Intrinsic Viscosity: Silent Drivers of Success

Molecular weight is one of the most misunderstood yet critical aspects of the role of PLGA polymer grade in long-acting release formulation.

Why Molecular Weight Matters

High MW PLGA:

- Longer release duration

- Higher mechanical strength

- Slower degradation

Low MW PLGA:

- Faster release

- Higher burst

- Rapid erosion

Intrinsic viscosity (IV) serves as a practical proxy for molecular weight and is a regulatory-relevant parameter in PLGA polymer characterization for generics.

4: Lactide:Glycolide Ratio and Its Impact on Degradation

The lactide:glycolide ratio defines hydrophobicity and degradation rate.

Common Ratios and Behavior

| Ratio | Degradation Speed | Typical Use |

|---|---|---|

| 50:50 | Fastest | Short-term depots |

| 65:35 | Moderate | Monthly injectables |

| 75:25 | Slow | 3–6 month release |

| 85:15 | Very slow | Long implants |

Incorrect interpretation of this ratio often leads to failures during scale-up and supplier changes, particularly when sourcing PLGA 50:50 polymers.

5: End-Group Chemistry: A Small Detail with Big Consequences

End-group chemistry is a subtle but decisive factor in the role of PLGA polymer grade in long-acting release formulation.

Acid-terminated PLGA

- Faster degradation

- Higher autocatalysis risk

- Higher burst release

Ester-capped PLGA

- Slower water penetration

- More controlled release

- Better long-term stability

These effects become especially critical in depot and PLGA drug-loading optimization strategies.

6: Analytical Characterization: Proving PLGA Grade Suitability

Regulatory success depends on demonstrating control over PLGA polymer grade.

Key Analytical Techniques

- GPC/SEC – Molecular weight distribution

- NMR – Monomer ratio & end-group confirmation

- DSC – Glass transition temperature

- FTIR – Chemical identity verification

- Residual solvent analysis – Process safety

Solvent selection itself must be justified, particularly when dissolving PLGA in pharmaceutical solvents or applying PLGA solubility enhancement strategies.

7: Regulatory Expectations: PLGA Grade Under the Microscope

Regulatory agencies no longer accept generic statements like “PLGA was selected for sustained release.”

They expect:

- Scientific rationale for grade selection

- Batch-to-batch consistency data

- Correlation between PLGA grade and release profile

- Risk assessment for polymer variability

Failure to address this has led to clinical holds and delayed approvals in multiple LAI programs.

Conclusion: PLGA Grade Is a Strategic Decision, Not a Commodity Choice

The role of PLGA polymer grade in long-acting release formulation extends far beyond polymer selection—it determines release kinetics, stability, manufacturability, and regulatory success.

Choosing the correct PLGA grade:

- Reduces development risk

- Shortens timelines

- Improves patient outcomes

- Strengthens regulatory confidence

Long-acting formulations succeed not by chance, but through deep scientific understanding of polymer behavior—supported by experienced partners such as a specialized PLGA reverse-engineering CRO.

FAQs on Role of PLGA Polymer Grade in Long-Acting Release

The “grade” of Poly(lactic-co-glycolic acid) (PLGA) polymer plays a crucial role in long-acting drug release systems by defining its physicochemical properties, which directly control the degradation rate, hydrophilicity, and the mechanism and duration of drug release.

PLGA polymers have been shown to be excellent delivery carriers for controlled administration of drugs, peptides and proteins due to their biocompatibility and biodegradability.

Effects of PLGA coating on properties of scaffolds. PLGA can be used to alter the bio-performance of tissue engineering scaffolds by virtue of its controllable biodegradability, desirable drug release behavior, proper biocompatibility, and stable mechanical characteristics.

PLGA polymers degrade by bulk hydrolysis of ester bonds, and breakdown to their constituent monomers, lactic and glycolic acids, which are eliminated from the body through Kreb’s cycle. The hydrolytic cleavage involves reaction with one molecule of water to form acidic and alcoholic end groups.

PLGA polymer grade determines how the polymer degrades, absorbs water, and allows drug diffusion. Small changes in molecular weight, lactide:glycolide ratio, or end-group chemistry can shift a formulation from controlled release to dose dumping. In long-acting injectables, PLGA is not an inert excipient—it actively governs release kinetics and stability.

Reference

- Injectable, long-acting PLGA formulations: Analyzing PLGA and

understanding microparticle formation. Journal of Controlled Release.http://kinampark.com/T-Polymers/files/All%20References/Park%202019%2C%20Injectable%2C%20long-acting%20PLGA%20formulations.%20Analyzing%20PLGA%20and%20understanding%20microparticle%20formation.pdf - Current trends in PLGA based long-acting injectable products: The industry perspective.https://www.tandfonline.com/doi/abs/10.1080/17425247.2022.2075845

- Long-acting injectable PLGA/PLA depots for leuprolide acetate: successful translation from bench to clinic.https://link.springer.com/article/10.1007/s13346-022-01228-0

- PLGA/PLA-Based Long-Acting Injectable Depot Microspheres in Clinical Use: Production and Characterization Overview for Protein/Peptide Delivery.https://www.mdpi.com/1422-0067/22/16/8884

- Accelerated in vitro release testing method for a long-acting peptide-PLGA formulation.European Journal of Pharmaceutics and Biopharmaceutics.https://www.sciencedirect.com/science/article/abs/pii/S0939641121001326