Introduction:

Thermogravimetric Analysis (TGA) is a fundamental thermal analysis technique used to measure changes in a material’s weight as a function of temperature or time under a controlled atmosphere. It is widely used in pharmaceuticals, polymers, chemicals, and material science to evaluate thermal stability, composition, and degradation behavior.

By monitoring mass loss during heating, cooling, or isothermal holding, TGA provides critical insights into moisture content, solvent loss, decomposition temperatures, oxidation behavior, and inorganic residue content.

Summary :

Thermogravimetric Analysis (TGA) is a technique that measures weight changes of a sample under controlled temperature conditions. It helps determine thermal stability, decomposition patterns, moisture content, volatile components, and residual ash. TGA is essential in pharmaceutical development, polymer characterization, quality control, and material research for understanding degradation mechanisms and predicting product performance under thermal stress.

1: What is Thermogravimetric Analysis (TGA)?

Thermogravimetric Analysis (TGA) is a thermal analysis technique that measures the change in mass of a material as a function of temperature or time under a controlled atmosphere. It is widely used to evaluate thermal stability, composition, moisture content, decomposition behavior, and oxidation characteristics of materials.

TGA is especially valuable in pharmaceuticals, polymers, petrochemicals, food, and materials science because it provides direct insight into how a substance behaves when exposed to heat—information critical for formulation, processing, storage, and quality control.

Thermogravimetric Analysis is an analytical method in which a small sample (typically 5–20 mg) is placed in a precision balance inside a furnace. The temperature is increased at a programmed rate, and the instrument continuously records weight changes.

The result is a TGA curve, which plots:

- Weight (%) on the Y-axis

- Temperature or Time on the X-axis

Any change in mass indicates a physical or chemical process occurring in the material.

2: How TGA Analysis Works: The Basics

TGA involves heating a small sample while it’s placed on a very sensitive scale inside a furnace. As the temperature increases, the sample might lose weight due to evaporation, decomposition, or chemical reactions. This weight change is tracked and shown on a graph, which helps scientists understand what’s happening inside the material. Each step in the process provides valuable information about the thermal behavior and structural integrity of the sample.

The weight loss curve allows experts to find out when a material starts to break down, how much moisture or filler it contains, and how long it can remain stable under heat. This makes TGA analysis an essential part of product design and quality control.

3: Key Principles Behind What is TGA Analysis

The principle of TGA is based on detecting weight changes due to:

- Moisture evaporation

- Loss of volatile compounds

- Thermal decomposition

- Oxidation reactions

- Combustion

- Reduction reactions

The experiment is conducted under controlled atmospheres such as:

- Nitrogen (inert atmosphere)

- Air or Oxygen (oxidative atmosphere)

- Argon or other gases depending on the study requirement

3.1 Controlled Heating Process

TGA testing often uses a constant heating rate, like 10°C per minute. This ensures that changes in weight are consistent and easy to track. It also helps repeat the test with the same results every time, which is important in research and quality control. By using a steady temperature increase, scientists can pinpoint exactly when thermal events like melting, decomposition, or evaporation occur. This consistency is essential for comparing different materials or formulations under the same conditions.

3.2 Special Gas Environments

TGA can be done using different gases like nitrogen, argon, or oxygen. Using these gases helps us see how materials react in different conditions, such as in air or without oxygen. This gives a clearer picture of how the material behaves in real life. For example, using oxygen can simulate burning or oxidation, while nitrogen helps observe thermal stability without chemical reactions. Choosing the right gas allows for more precise and targeted testing based on the product’s application.

3.3 Micro-Level Accuracy

The balance used in TGA is extremely sensitive and can detect even tiny weight changes. This is especially helpful for industries like pharmaceuticals or aerospace, where even small changes can make a big difference in safety and performance. It allows for accurate analysis using just a small amount of sample, making it both cost-effective and efficient. Such precision is crucial when testing expensive or limited-quantity materials that require high-stakes evaluation.

👉 DSC Analysis of Biodegradable Polymers

4: Types of TGA Analysis Methods

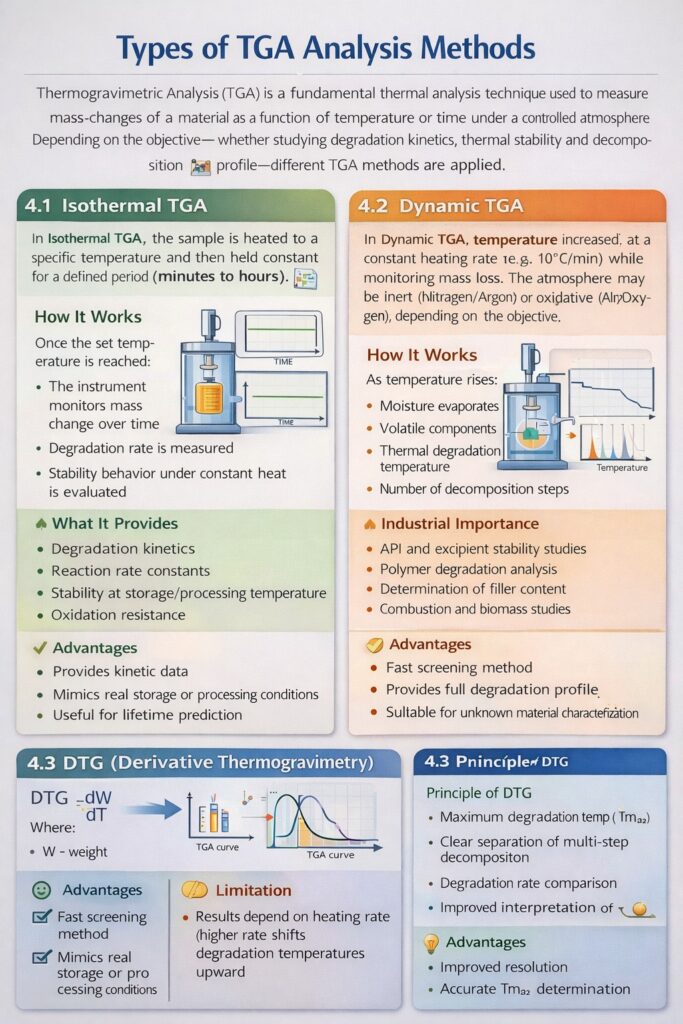

4.1 Isothermal TGA

In Isothermal TGA, the sample is heated to a specific temperature and then held constant for a defined period (minutes to hours).

How It Works

Once the set temperature is reached:

- The instrument monitors mass change over time

- Degradation rate is measured

- Stability behavior under constant heat is evaluated

What It Provides

- Degradation kinetics

- Reaction rate constants

- Stability at storage/processing temperature

- Oxidation resistance

The result is a mass vs. time curve rather than mass vs. temperature.

Industrial Importance

Used when you want to simulate real-world conditions, such as:

- Shelf-life prediction of pharmaceuticals

- Polymer aging studies

- Long-term thermal stability testing

- Oxidation behavior at fixed temperatures

Advantages

- Provides kinetic data

- Mimics real storage or processing conditions

- Useful for Arrhenius-based shelf-life prediction

Limitation

Time-consuming compared to dynamic TGA.

4.2 Dynamic TGA

In Dynamic TGA, the temperature is increased continuously at a constant heating rate (e.g., 5, 10, or 20 °C/min) while monitoring mass loss. The atmosphere can be inert (Nitrogen/Argon) or oxidative (Air/Oxygen), depending on the objective.

How It Works

As temperature rises:

- Moisture evaporates

- Volatile components are released

- Thermal degradation begins

- Oxidation or combustion may occur

Each event appears as a stepwise weight loss on the thermogram.

What It Provides

- Onset degradation temperature

- Peak degradation temperature (from DTG curve)

- Number of decomposition steps

- Thermal stability ranking

- Residual ash content

Industrial Importance

This is the most widely used TGA method because it quickly provides a full thermal profile.

Used in:

- API and excipient stability studies

- Polymer degradation analysis

- Determination of filler content

- Combustion studies

Advantages

- Fast screening method

- Provides complete degradation profile

- Suitable for unknown material characterization

Limitation

Results depend on heating rate (higher rate shifts degradation to higher temperatures).

4.3 DTG (Derivative Thermogravimetry)

Derivative Thermogravimetry (DTG) is a data treatment technique used in Thermogravimetric Analysis (TGA), where the rate of weight loss is plotted against temperature or time.

While TGA shows how much weight is lost, DTG shows how fast the weight is lost.

Mathematically: DTG=dWdTDTG = \frac{dW}{dT}DTG=dTdW

Where:

- W = weight

- T = temperature

The output is called a DTG curve.

Principle of DTG

As the sample is heated:

- Weight decreases due to moisture loss, solvent evaporation, or decomposition.

- The instrument calculates the first derivative of the TGA curve.

- Each decomposition event appears as a peak in the DTG curve.

👉 In TGA: You see steps.

👉 In DTG: You see peaks.

Interested in transition temperatures? Learn more at:

👉 DSC Glass Transition Analysis – Accurate Tg Detection

5: Industrial Examples of What is TGA Analysis

5.1 In Pharmaceuticals

TGA helps in checking the shelf life of medicines, how stable they are, and how they lose moisture over time. This is key in making sure medicines work well and are safe for patients.

👉 DSC Analysis in a Pharmaceutical Case Study

5.2 In Plastic and Polymer Production

Manufacturers use TGA to check for leftover solvents, filler content, and the point where materials begin to break down. This improves product performance and consistency.

👉 DSC Analysis in Montreal – Polymer & Thermal Services

5.3 In Battery Research

TGA is used to study how battery parts behave under heat. It ensures safety by helping design batteries that are stable and less likely to fail or overheat.

5.4 In Food and Agriculture

This technique measures how much moisture is in food, whether packaging holds up under heat, and how long a product might last. These results help improve food quality and packaging standards.

6: Applications of TGA Analysis in Real Industries

TGA is used in many sectors to improve materials and meet safety standards. Here are some common uses:

- Polymers: Analyze degradation and check filler levels

- Pharmaceuticals: Track moisture, shelf-life, and drug stability

- Batteries: Study thermal safety and composition of battery parts

- Rubber and Composites: Measure carbon black and detect impurities

- Food and Packaging: Monitor moisture levels and predict expiration dates

Each of these uses helps companies make better, safer, and longer-lasting products.

7: Comparing TGA with DSC Analysis

TGA checks weight changes, while DSC (Differential Scanning Calorimetry) measures heat flow during heating or cooling. When used together, they give a full thermal picture of a material. For example, TGA shows when something burns or breaks down, while DSC shows when it melts or solidifies. This combined data is especially useful for complex materials that undergo both physical and chemical changes. Using both methods helps researchers and engineers make more accurate predictions about product behavior and performance under heat.

Together, these tools help scientists and engineers make smarter, safer material choices. For a deeper dive into how TGA compares to DSC, visit our guide:

👉 DSC vs. TGA – A Simple Comparison Guide

8: Why Choose ResolveMass Laboratories for TGA Analysis?

At ResolveMass Laboratories, we use high-end instruments and follow global standards like ISO for accurate, reliable results. Our experienced scientists provide custom reports tailored to your product and industry. Whether you’re in pharma, polymers, batteries, or food—our team helps bring your innovation to life with trustworthy TGA analysis services.

Explore our core services:

Conclusion – The Future of TGA Analysis

What is TGA Analysis? It’s not just a scientific term—it’s a critical tool in today’s manufacturing and research industries. It helps companies design safer, more efficient, and more reliable products. From lab testing to product launch, TGA analysis supports innovation at every step. By understanding how materials respond to heat, businesses can reduce risks, meet regulations, and speed up development cycles. As industries continue to evolve, the role of TGA in quality assurance and product performance will only grow more important.

At ResolveMass Laboratories, we continue to help clients meet their goals through accurate and expert thermal testing.

FAQs – What is TGA Analysis and Common Questions

The principle of TGA is based on measuring the change in a material’s weight as it is heated over time. When the sample is exposed to heat, it may lose or gain mass due to processes like evaporation, decomposition, or oxidation. These weight changes help understand the material’s thermal stability and composition.

The three main types of TGA are Dynamic TGA, Isothermal TGA, and DTG (Derivative Thermogravimetry). Dynamic TGA increases temperature over time, isothermal keeps the temperature constant, and DTG shows how fast the weight changes. Each type gives different insights depending on the material and goal of testing.

TGA is analysed by studying the weight-loss curve recorded during the heating process. The curve shows how the sample’s mass changes with temperature or time. By looking at key points, such as sudden drops in weight, experts can identify thermal events like moisture loss, decomposition, or oxidation.

A typical TGA test can take anywhere from 30 minutes to 2 hours, depending on the heating rate, final temperature, and the nature of the sample. If multiple steps or slow heating is used, the test may take longer. Shorter tests are often used for routine checks.

Mass change in TGA is calculated by subtracting the final weight of the sample from its starting weight, then expressing the result as a percentage. For example, if a sample starts at 100 mg and ends at 80 mg, the mass loss is 20%. This helps identify the amount of moisture, filler, or other volatile components.

TGA is primarily a quantitative method because it measures exact weight changes during heating. However, it can also give qualitative information about thermal events and reaction behavior. When combined with other tests, it provides a full picture of a material’s thermal properties.

Several factors can affect TGA results, including heating rate, sample size, gas environment, and material properties. Even the placement of the sample in the pan can influence the accuracy. Controlling these factors is important to get reliable and repeatable results.

Common gases used in TGA include nitrogen, argon, oxygen, and air. Inert gases like nitrogen or argon prevent oxidation and allow pure thermal study, while reactive gases like oxygen help observe how materials burn or degrade in air. The gas type depends on the goal of the test.

References

- Comparative study in the identification of liquid to solid transition phase with DSC, Raman spectra analysis and chemiometrics methods applied to phase change materials used for icing-delay in civil engineering infrastructures

- Thermogravimetric Analyzer

- Thermal Analysis Methods.https://link.springer.com/chapter/10.1007/978-981-99-0546-1_3

- Applications of Thermal Analysis and Coupled Techniques in Pharmaceutical Industry.https://akjournals.com/view/journals/10973/68/2/article-p335.xml

- Comprehensive Insights into Thermo Gravimetric Analysis.https://link.springer.com/chapter/10.1007/978-981-96-5996-8_19