Polymer testing is a critical aspect of modern materials science, ensuring that polymers used in various industries—from healthcare to aerospace—meet regulatory standards and performance requirements. With the increasing demand for high-quality polymeric materials, advanced testing techniques are essential for evaluating properties such as molecular weight, mechanical strength, thermal stability, and chemical composition.

In this blog, we will explore the latest trends and technologies shaping the future of polymer testing in Canada and the United States. We will also discuss key regulatory requirements, innovative analytical techniques, and industry applications that are driving advancements in this field.

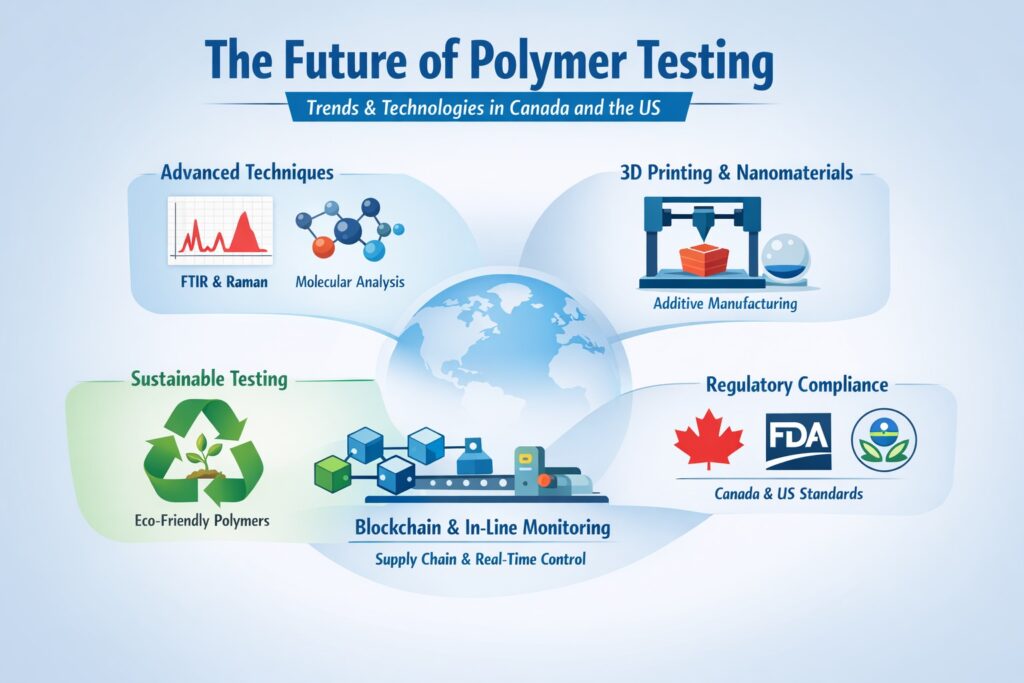

Key Highlights: The Future of Polymer Testing

- Polymer testing ensures material quality, safety, and regulatory compliance across industries like healthcare, aerospace, and packaging.

- Advanced techniques—such as FTIR, Raman spectroscopy, GPC, DSC, TGA, and rheometry—evaluate chemical, mechanical, and thermal properties.

- Emerging trends include automation, AI-driven analysis, additive manufacturing (3D printing) testing, and nanocomposite evaluation.

- Sustainable and eco-friendly approaches, including biodegradable polymer testing and life cycle analysis, are shaping the industry.

- Blockchain and real-time in-line monitoring improve supply chain transparency, process control, and predictive quality management.

- Regulatory compliance in Canada and the US is guided by agencies like Health Canada, the FDA, ASTM, ISO, and the EPA.

Importance of Polymer Testing

Polymers are used in diverse applications, ranging from medical devices and automotive components to packaging and textiles. Ensuring their reliability and performance requires comprehensive testing methodologies that evaluate their physical, chemical, and mechanical properties. Polymer testing helps manufacturers:

- Verify compliance with regulatory standards

- Improve product quality and durability

- Enhance safety and performance in real-world applications

- Optimize manufacturing processes

- Develop innovative materials for future applications

Emerging Trends in Polymer Testing

Integration of Automation in Polymer Testing

Automation is transforming polymer testing by streamlining repetitive processes and reducing human error. Robotic sample handling and automated testing platforms now enable high-throughput screening of polymer samples, significantly reducing turnaround times for analysis. These systems can handle multiple analytical techniques simultaneously, ensuring consistent and reproducible results.

Additionally, integration with digital data management tools allows manufacturers to store, track, and analyze testing data efficiently. This not only improves traceability but also supports regulatory compliance by maintaining accurate records of polymer performance over time. As automation becomes more sophisticated, polymer laboratories in Canada and the US are increasingly adopting these technologies to enhance productivity and reliability.

1. Advanced Spectroscopic Techniques

Spectroscopic methods, such as Fourier Transform Infrared (FTIR) Spectroscopy and Raman Spectroscopy, have become essential tools for polymer characterization. These techniques allow for rapid identification of polymer composition, molecular structure, and potential contaminants.

FTIR Spectroscopy

FTIR spectroscopy is widely used to determine functional groups present in a polymer, enabling manufacturers to verify material composition and detect degradation over time.

Polymer Testing in Additive Manufacturing (3D Printing)

The rise of additive manufacturing has introduced new challenges for polymer testing. Polymers used in 3D printing require precise control over viscosity, melting behavior, and layer adhesion. Specialized testing methods are now being developed to evaluate polymer performance in additive processes, ensuring parts maintain their intended mechanical and thermal properties.

Furthermore, post-processing techniques such as annealing or UV curing can alter polymer characteristics, making continuous testing critical. Analytical methods like DSC, TGA, and rheometry are adapted to assess these changes, allowing manufacturers to optimize both material selection and printing parameters. This integration of testing and manufacturing ensures high-quality outputs for industrial and medical applications.

Raman Spectroscopy

Raman spectroscopy provides complementary data to FTIR by analyzing molecular vibrations. It is particularly useful for characterizing complex polymer blends and composites.

2. Chromatographic Methods for Molecular Weight Analysis

The molecular weight of a polymer significantly impacts its mechanical properties, solubility, and processing behavior. Gel Permeation Chromatography (GPC), also known as Size Exclusion Chromatography (SEC), is a powerful technique for measuring molecular weight distribution.

Gel Permeation Chromatography (GPC)

GPC is used extensively in the polymer industry to assess polymer chain length and detect inconsistencies in production. Advances in multi-detection GPC techniques, such as combining refractive index and light scattering detectors, have improved the accuracy of molecular weight determination.

3. Thermal Analysis for Stability and Performance Evaluation

Thermal analysis techniques provide valuable insights into polymer behavior under different temperature conditions. These techniques include:

Differential Scanning Calorimetry (DSC)

DSC measures heat flow in a polymer sample as it undergoes phase transitions, such as melting or crystallization. It helps determine thermal stability, glass transition temperature, and curing characteristics.

Thermogravimetric Analysis (TGA)

TGA evaluates the thermal degradation of polymers by measuring weight loss as a function of temperature. It is crucial for assessing polymer stability and predicting material lifespan.

4. Mechanical and Rheological Testing

Mechanical and rheological testing assess the strength, flexibility, and processability of polymers under various conditions.

Dynamic Mechanical Analysis (DMA)

DMA measures a polymer’s viscoelastic properties by applying oscillating stress. It is particularly useful for studying temperature-dependent mechanical behavior.

Rheometry

Rheometry evaluates polymer flow behavior, helping manufacturers optimize processing conditions for extrusion, molding, and coating applications.

Nanocomposite Polymer Testing

Nanocomposite polymers, which incorporate nanoparticles such as graphene or silica, offer enhanced strength, thermal stability, and barrier properties. However, their complex microstructure requires specialized testing methods to evaluate dispersion, particle-polymer interactions, and overall material performance. Techniques such as transmission electron microscopy (TEM) and scanning electron microscopy (SEM) are now widely employed for structural analysis at the nanoscale.

Mechanical testing is also critical for nanocomposites, as the addition of nanoparticles can significantly affect flexibility and toughness. By combining nanoscale imaging with conventional mechanical and thermal tests, researchers and manufacturers in Canada and the US can design polymers that meet rigorous industrial and environmental standards while leveraging the benefits of nanotechnology.

5. Sustainable and Eco-Friendly Testing Approaches

With increasing emphasis on sustainability, polymer testing is evolving to support eco-friendly materials and biodegradable alternatives. Biodegradability testing and life cycle analysis (LCA) are now integral to assessing the environmental impact of polymer products.

Blockchain for Polymer Supply Chain Transparency

Blockchain technology is emerging as a tool to enhance transparency in the polymer industry. By recording polymer origin, testing results, and compliance certifications on a secure digital ledger, manufacturers can provide verifiable proof of material quality to clients and regulators. This reduces the risk of counterfeit materials and ensures consistent performance across the supply chain.

Moreover, blockchain facilitates traceability for recycled or biodegradable polymers, supporting circular economy initiatives. Consumers and industrial buyers increasingly demand evidence of sustainable practices, and blockchain-enabled polymer testing allows companies to demonstrate both environmental responsibility and product integrity in a transparent and auditable manner.

Regulatory Landscape for Polymer Testing in Canada and the US

Ensuring compliance with regulatory standards is essential for polymer manufacturers. In Canada and the United States, various agencies oversee polymer testing requirements:

- Health Canada regulates polymers used in medical devices, food packaging, and pharmaceuticals.

- The U.S. Food and Drug Administration (FDA) sets guidelines for polymers in healthcare and food contact applications.

- ASTM International and ISO Standards provide standardized testing methodologies for polymer properties.

- Environmental Protection Agency (EPA) assesses the environmental impact of polymer materials.

Compliance with these regulations ensures that polymer products meet safety and performance standards before reaching the market.

Future Innovations in Polymer Testing

AI and Machine Learning in Polymer Characterization

Artificial Intelligence (AI) and machine learning are revolutionizing polymer testing by enabling predictive analysis and automated data interpretation. AI-driven systems can identify trends in polymer properties, optimize testing protocols, and enhance quality control processes.

High-Resolution Imaging and 3D Analysis

Advanced imaging techniques, such as Atomic Force Microscopy (AFM) and X-ray Computed Tomography (XCT), provide nanoscale insights into polymer structure and defects. These technologies improve failure analysis and material design.

Real-Time In-Line Monitoring of Polymer Production

In-line monitoring of polymer production is gaining traction as a means to detect deviations in real time. Advanced sensors and spectroscopic probes installed on production lines can continuously measure properties such as molecular weight, viscosity, and thermal behavior without halting manufacturing. This approach allows for immediate adjustments, minimizing waste and ensuring uniform product quality.

Integration of real-time monitoring with AI-driven predictive analytics further enhances polymer process control. By identifying trends and potential defects before they propagate, manufacturers can reduce downtime, save costs, and maintain compliance with stringent regulatory standards. The combination of in-line monitoring and smart analytics is set to redefine polymer testing as a proactive rather than reactive process.

Sustainable and Biodegradable Polymer Testing

As the industry shifts towards sustainable materials, testing methods for biodegradable polymers, such as polylactic acid (PLA) and polycaprolactone (PCL), are gaining traction. Evaluating compostability, degradation rates, and mechanical integrity ensures the viability of eco-friendly alternatives.

Conclusion

Polymer testing is evolving with cutting-edge technologies and regulatory advancements to meet the growing demand for high-performance materials. Innovations in spectroscopy, chromatography, thermal analysis, and AI-driven testing are shaping the future of polymer characterization in Canada and the US. As industries move toward sustainability and advanced material development, polymer testing will continue to play a pivotal role in ensuring product safety, compliance, and performance.

REFERENCES

- Polymer Testing. (n.d.). ESI. Retrieved January 13, 2026, from https://esi.in/publications/polymer-testing

- Polymer Testing. (n.d.). JournalSeeker. Retrieved January 13, 2026, from https://journalseeker.com/journal.php?q=polymer%20testing

- Malucelli, G. (2024). Polymer analysis and characterization. PubMed Central (PMC). https://pmc.ncbi.nlm.nih.gov/articles/PMC11678654/

LET’S CONNECT

For expert polymer testing services, regulatory compliance guidance, and customized analysis, contact ResolveMass Laboratories Inc. today. Our team of specialists ensures precise and reliable polymer characterization tailored to your industry needs.

Peptide Sameness Study vs Biosimilar Comparability: What’s the Difference?

Introduction: Peptide Sameness vs Biosimilar Comparability is one of the most misunderstood concepts in modern…

Case Study: Root Cause Investigation of Unexpected NDMA Spike in Finished Product

Introduction In this NDMA Root Cause Investigation Case Study, we examine a real-world scenario involving…

Selecting the Right Nitrosamine Testing CRO: A Technical Due Diligence Checklist

Introduction Nitrosamine Testing CRO Selection requires detailed scientific evaluation and regulatory awareness. Global authorities continue…

Case Study: Sameness Evaluation of Semaglutide Generic project submission to Health Canada

Introduction: Semaglutide Sameness Evaluation for Health Canada is a scientifically rigorous analytical process required to…

Analytical Testing Services for Peptide-Oligonucleotide Conjugates

Introduction: Why Specialized Peptide Oligonucleotide Conjugate Analysis Is Essential Peptide Oligonucleotide Conjugate Analysis is critical…

NDA vs ANDA Nitrosamine Data Requirements: What Sponsors Must Submit

Introduction: The global pharmaceutical industry is facing strict regulatory control for mutagenic impurities, especially nitrosamines….